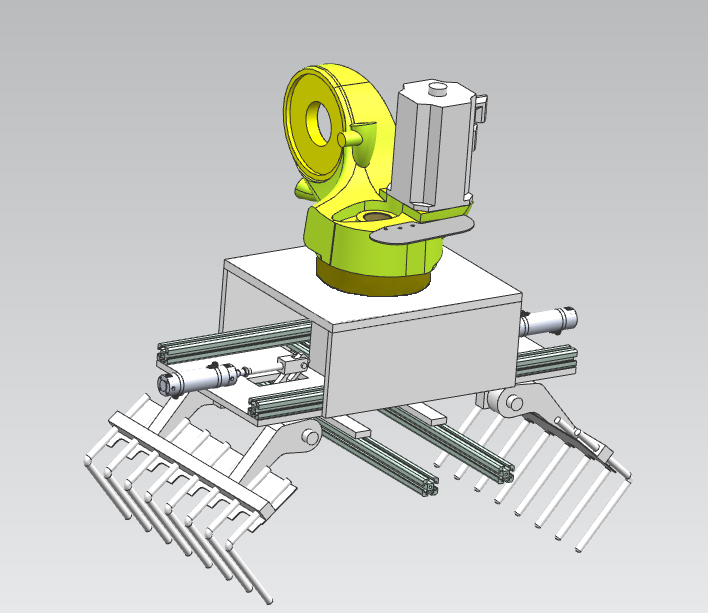

Palletizing robot single claw gripper

1. The single-claw gripper has a relatively simple structure and a compact overall design, which not only reduces the manufacturing and assembly costs, but also reduces the possible failure points caused by complex structures.

2. The control logic is relatively simple, and only needs to control the movement of a single claw, which makes it easier to achieve precise control during programming and debugging.

3. The single-claw gripper can be equipped with high-precision sensors and advanced control systems to more accurately locate and grasp goods.

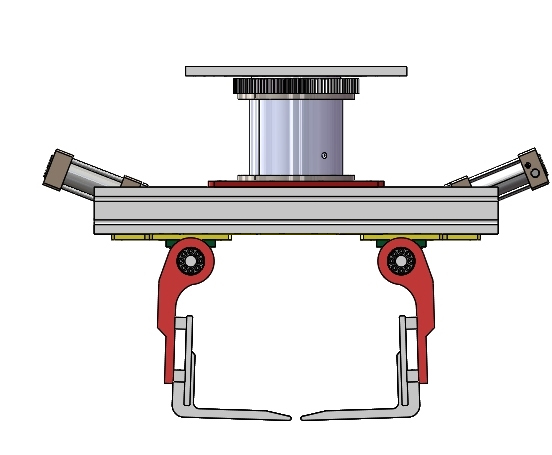

4. When a single claw grasps goods, all the grasping force is concentrated on one point or one surface, which can provide a more concentrated and stable grasping force.

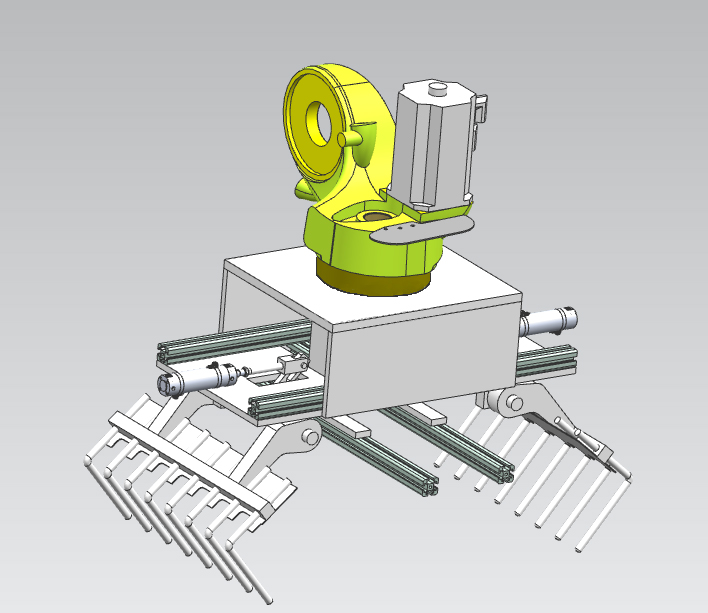

5. Due to its relatively small and flexible structure, the single-claw gripper is easier to operate in a small space and can be more conveniently installed and used.

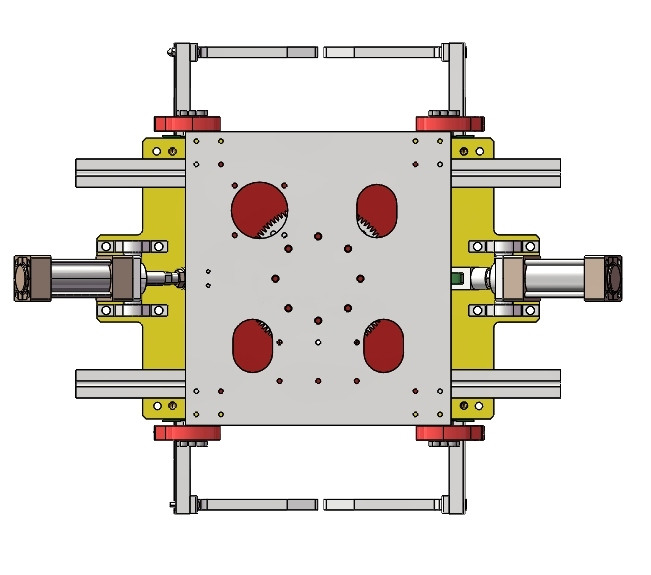

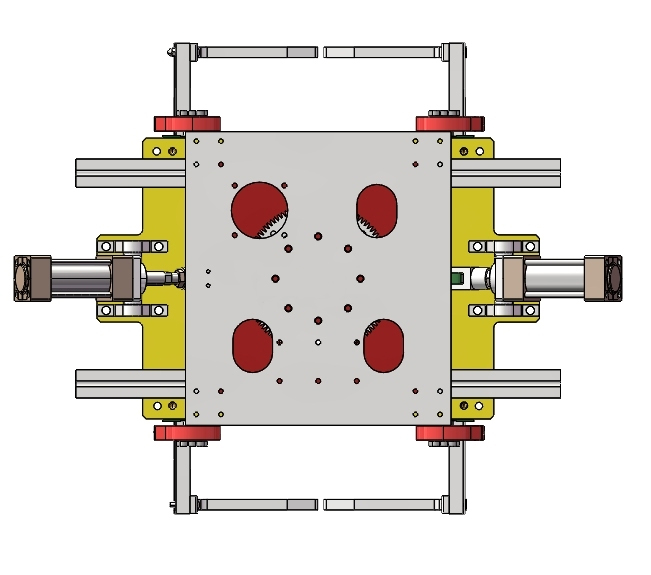

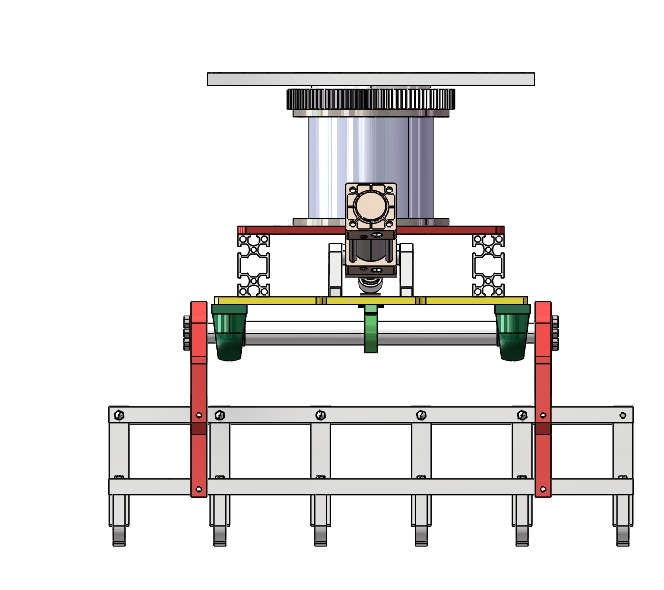

High-strength aluminum alloy or stainless steel is usually used. The claw body made of aluminum alloy is light in weight, which can reduce the load of the robot and improve the running speed and flexibility.

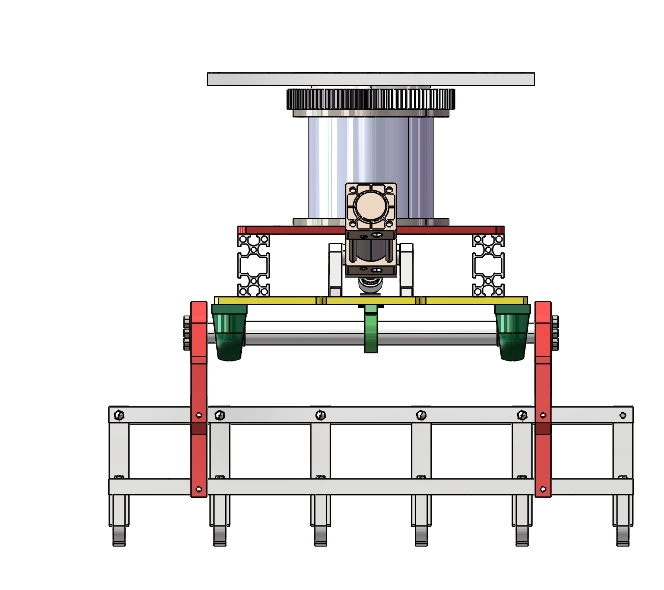

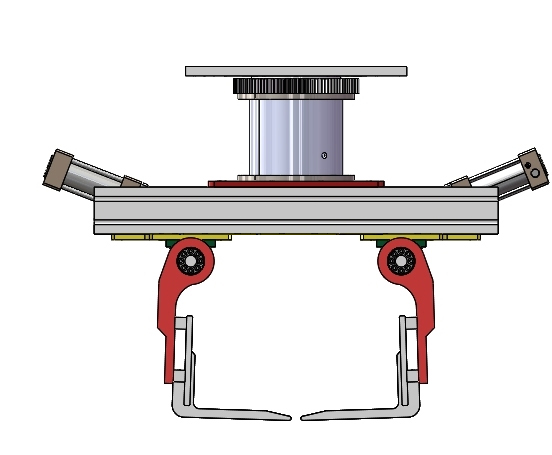

It is connected to the palletizing robot arm through high-precision joints and transmission devices. The joints mostly use harmonic reducers or planetary reducers with high transmission accuracy and large torque, which can ensure the accuracy and stability of single claw movement.

Depending on the application scenarios and grasping objects, the appearance shape of the single-claw gripper has a variety of designs.

The gripping force and position can be automatically adjusted according to the weight, shape and size of the goods.

It is deeply integrated with the palletizing robot control system and can complete palletizing tasks in collaboration with the robotic arm according to preset programs and instructions.