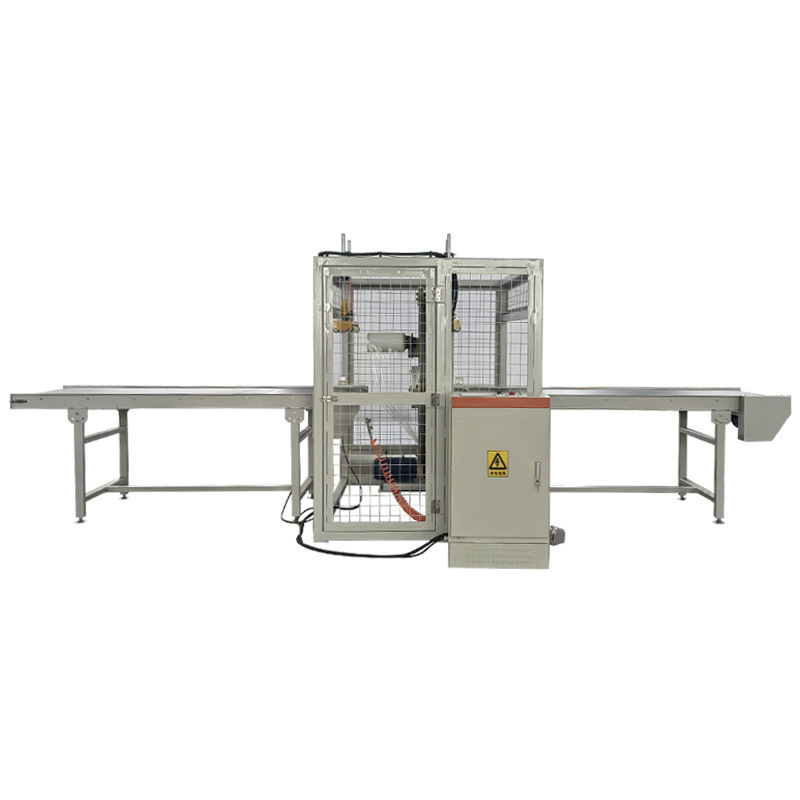

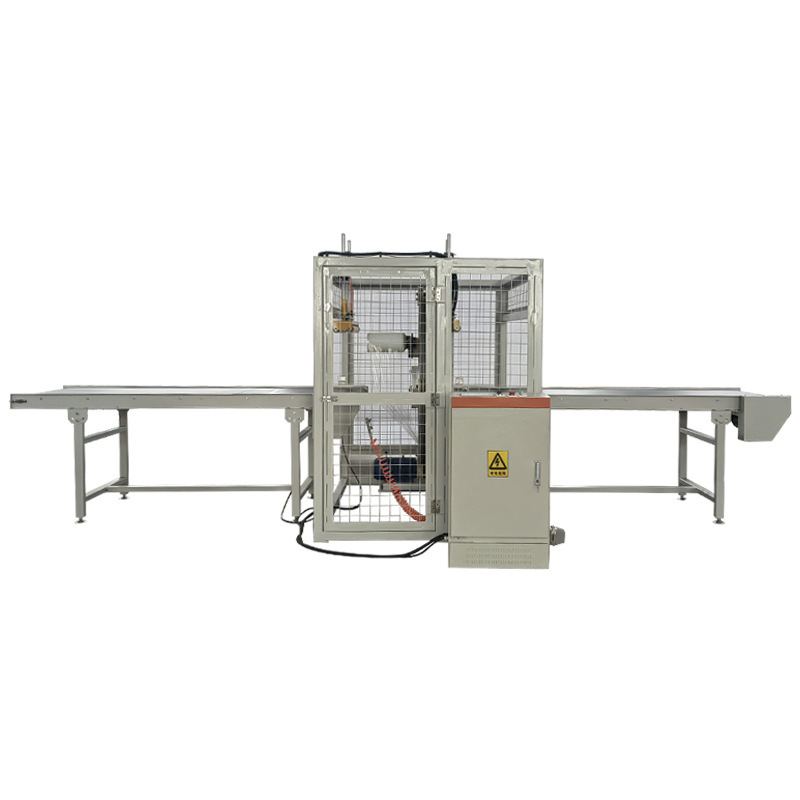

Horizontal wrapping machine

1. Fast packaging speed: able to complete the packaging task of a large number of products in a short time, significantly improving production efficiency.

2. Strong continuous operation capability: It can operate stably for a long time and carry out packaging operations without interruption, ensuring the smoothness of the production process and further improving the overall production efficiency.

3. Reduce labor costs: The degree of automation is high, which can replace a large number of manual operations and reduce dependence on manpower.

3. Save packaging materials: Through precise control systems and reasonable packaging design, the usage of packaging materials can be effectively controlled and the cost of packaging materials can be reduced.

4. Good packaging effect: packaging parameters can be flexibly adjusted according to the shape, size and packaging requirements of different products.

5. Strong product adaptability: able to adapt to product packaging of various shapes and sizes, whether long bars, pipes, or profiles.

The packaging of products is achieved by wrapping and wrapping the packaging material around the horizontally placed products. The machine is usually equipped with a feeding device, a wrapping device, a cutting device and a control system, which can automatically complete the packaging process and improve packaging efficiency and quality.

Application areas:

Food industry: Packaging of products such as biscuits, candies, and fruits can be customized according to the characteristics and packaging requirements of different foods.

Industrial field: Applied to the packaging of mechanical parts, electronic components, building materials and other products, which can meet the needs of large-scale production, such as the outer packaging of metal pipes, plastic steel profiles, sandwich panels and other products.

Logistics and warehousing industry: Wrapping the pallet goods to ensure the stability and safety of the goods during transportation and storage, and prevent the goods from being damaged, damp, scattered, etc.

Efficiency: The packaging speed is fast, and it can complete the packaging task of a large number of products in a short time, significantly improving production efficiency; it has strong continuous operation capability, and can run stably for a long time, and carry out packaging operations without interruption, ensuring the smoothness of the production process.

Economical: Reduce labor costs, have a high degree of automation, can replace a large number of manual operations, reduce reliance on manpower, thereby reducing the company's labor costs; save packaging materials, through precise control systems and reasonable packaging design, It can effectively control the usage of packaging materials, avoid waste and reduce the cost of packaging materials.

Good packaging quality: Packaging parameters can be flexibly adjusted according to the shape, size and packaging requirements of different products, such as the number of winding layers, the overlap of the packaging belt, the tightness, etc., to make the packaging more compact, firm and beautiful, and effectively protect the product from damage during transportation and storage; the product has strong adaptability and can adapt to the packaging of products of various shapes and sizes. Whether it is long bars, tubes, profiles, or flat plates, etc., good packaging effects can be achieved by adjusting equipment parameters and replacing some accessories. It has strong versatility and flexibility.

Technical Support: We have a professional technical team to provide customers with long-term technical support, including answering technical questions encountered by customers during use, providing suggestions for equipment upgrades and improvements, etc., to help customers better use and manage equipment and improve production efficiency.