Tape wrapping machine

1. The tape wrapping machine adopts an advanced control system, which can accurately set the key parameters of the tape winding speed, tension, and number of winding layers.

2. Whether it is a thin plastic tape or a thick fiber tape, it can maintain constant tension so that the tape fits tightly to the surface of the product.

3. It has strong continuous operation capability, and can operate stably for a long time without frequent downtime or replacement of operators.

4. It can adapt to the winding needs of products of different shapes, sizes and materials.

5. There is no strict restriction on the material of the product. Whether it is metal, plastic, wood, glass or ceramic, it can be packaged on the tape wrapping machine.

6. It can be compatible with tapes of different types and specifications. Whether it is a narrow tape of a few millimeters or a tape with a width of tens of millimeters or even hundreds of millimeters, it can be used smoothly on the machine.

The tape wrapping machine is a mechanical device specially used for wrapping various products with tape, and is widely used in many fields such as industrial production, logistics and warehousing. It wraps the tape evenly and tightly around the surface of the product through automatic or semi-automatic operation, which plays a protective role and effectively improves the efficiency and quality of product packaging.

It has a highly automated operating process and can automatically complete a series of actions such as conveying, winding, and cutting of the tape, greatly improving packaging efficiency, reducing manual intervention, and reducing labor intensity and labor costs.

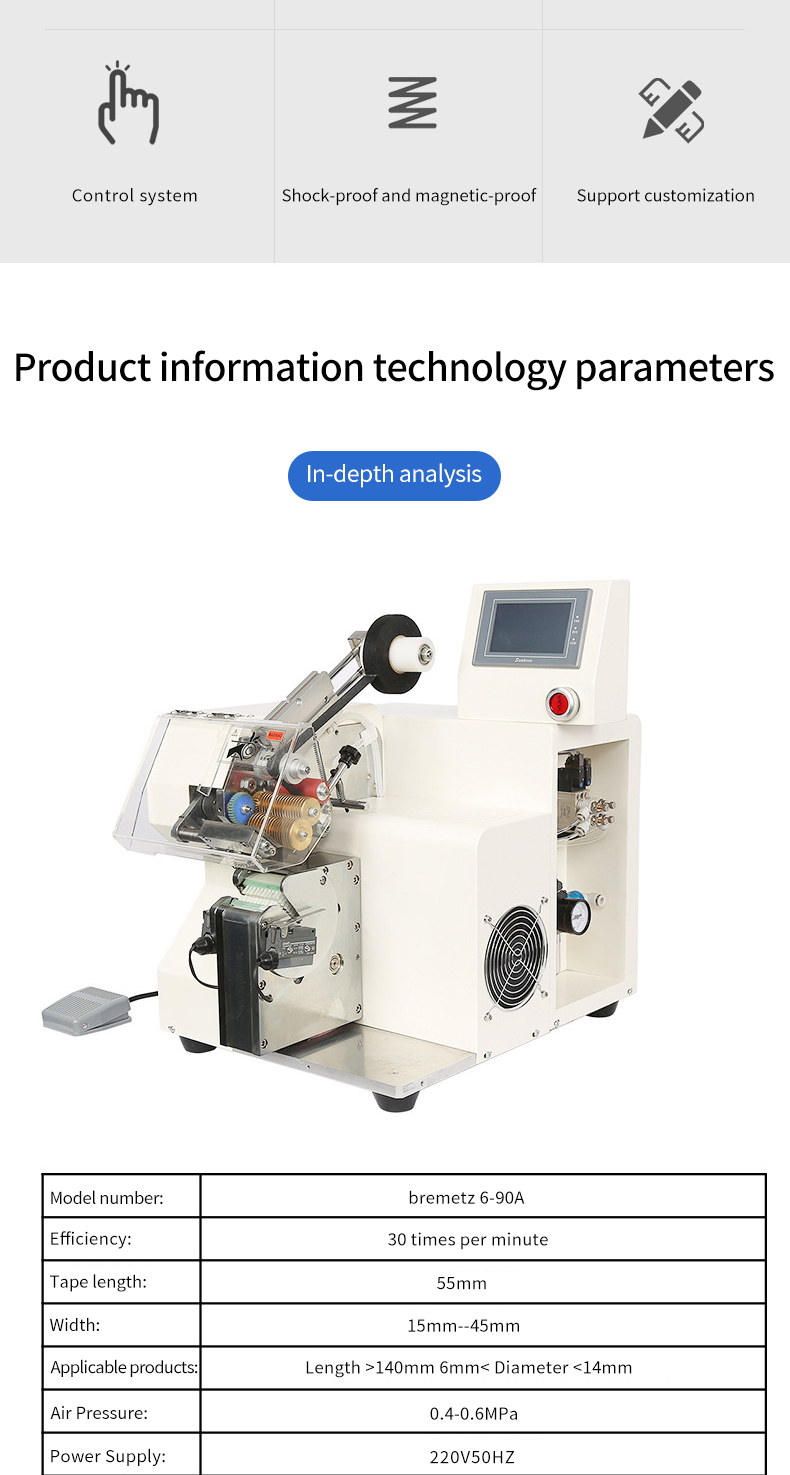

Model number:Bremetz 6-90A

Efficiency:30 times per minute

Tape length:55mm

Width:15mm--45mm

Applicable products:Length >140mm 6mm< Diameter <14mm

Air Pressure:0.4-0.6 MPa

Power Supply:220V50HZ

power:200W

Weight:48kg

Overall dimensions:W300XH250XD500

The use of advanced control systems and high-precision sensors can accurately control the tape winding parameters, such as winding speed, tension, number of layers, etc., to ensure that the tape is evenly and tightly wound on the product surface, avoiding problems such as the tape being too loose or too tight, or unevenly wound.

The human-machine interface is simple and intuitive. Operators can easily start and control the equipment by simply setting parameters and inputting operating instructions through the touch screen.

The use of high-quality mechanical parts and electrical components, and strict quality inspection and performance testing ensure that the equipment has stable and reliable performance during long-term continuous operation.

Equipped with complete safety protection devices, such as emergency stop button, protective door, light curtain sensor, etc., when the equipment is abnormal or the operator makes a mistake, the equipment can be stopped in time to ensure the personal safety of the operator and the normal operation of the equipment.

Application areas:

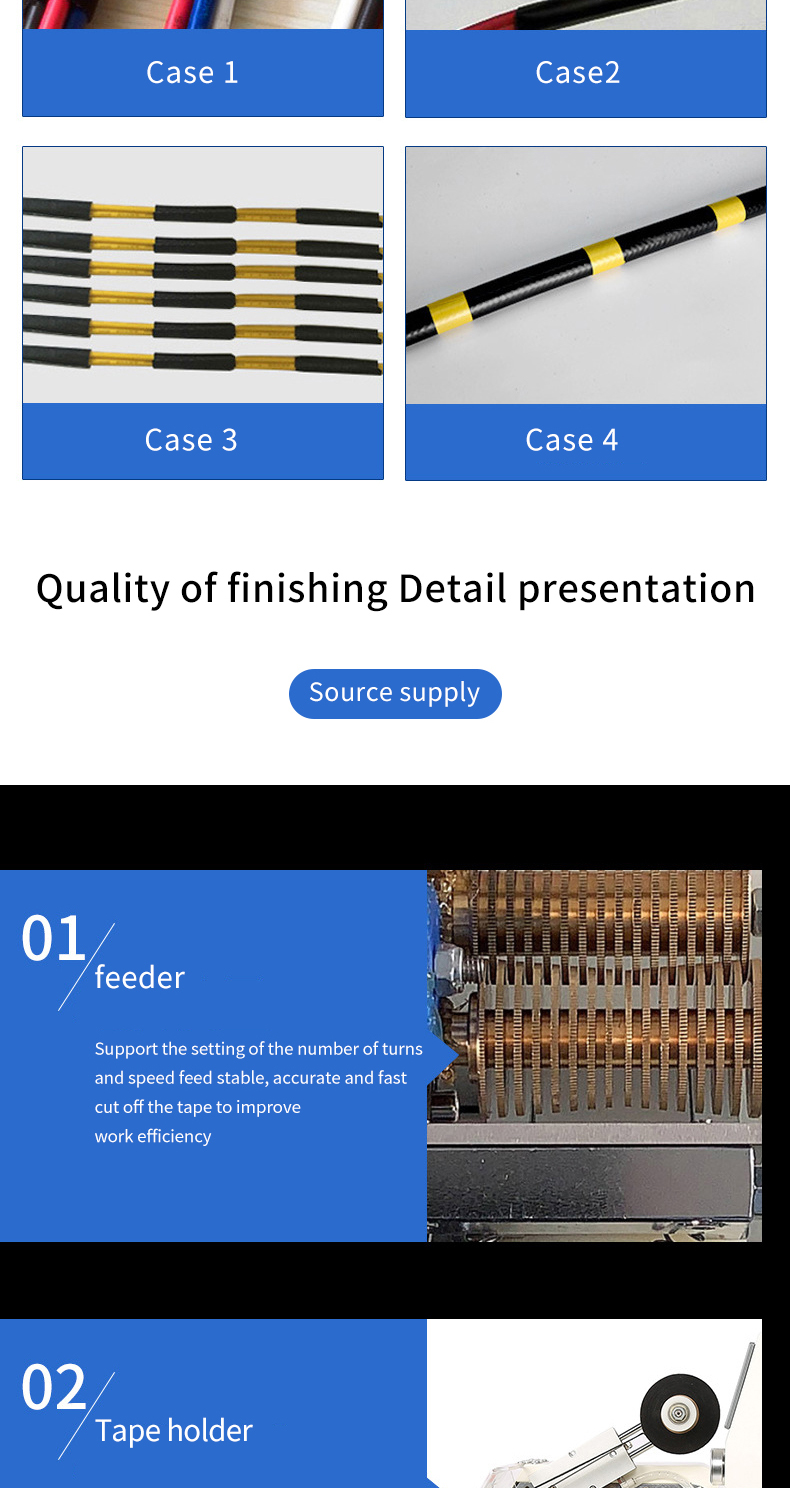

Industrial manufacturing: In the machinery manufacturing, automobile manufacturing and other industries, it is used to package various parts, semi-finished products and finished products.

Logistics and warehousing: Wrapping and packaging cargo pallets, cartons, wooden boxes, etc. to enhance the stability and integrity of the goods.

Commercial packaging: Used to reinforce and decorate the outer packaging of products, such as packaging boxes, packaging bags, etc.

Other fields: In addition to the above fields, the tape wrapping machine can also be used in agriculture, construction, home furnishing and other industries.