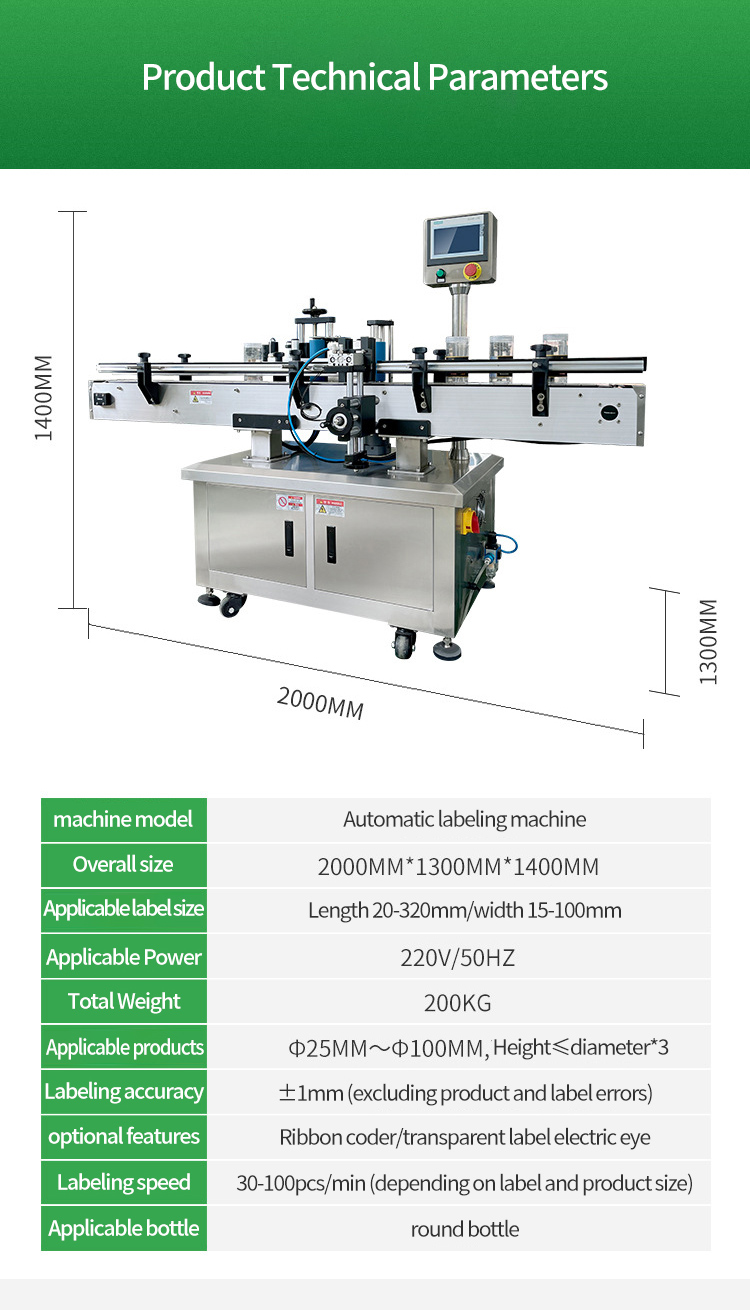

High speed automatic labeling machine

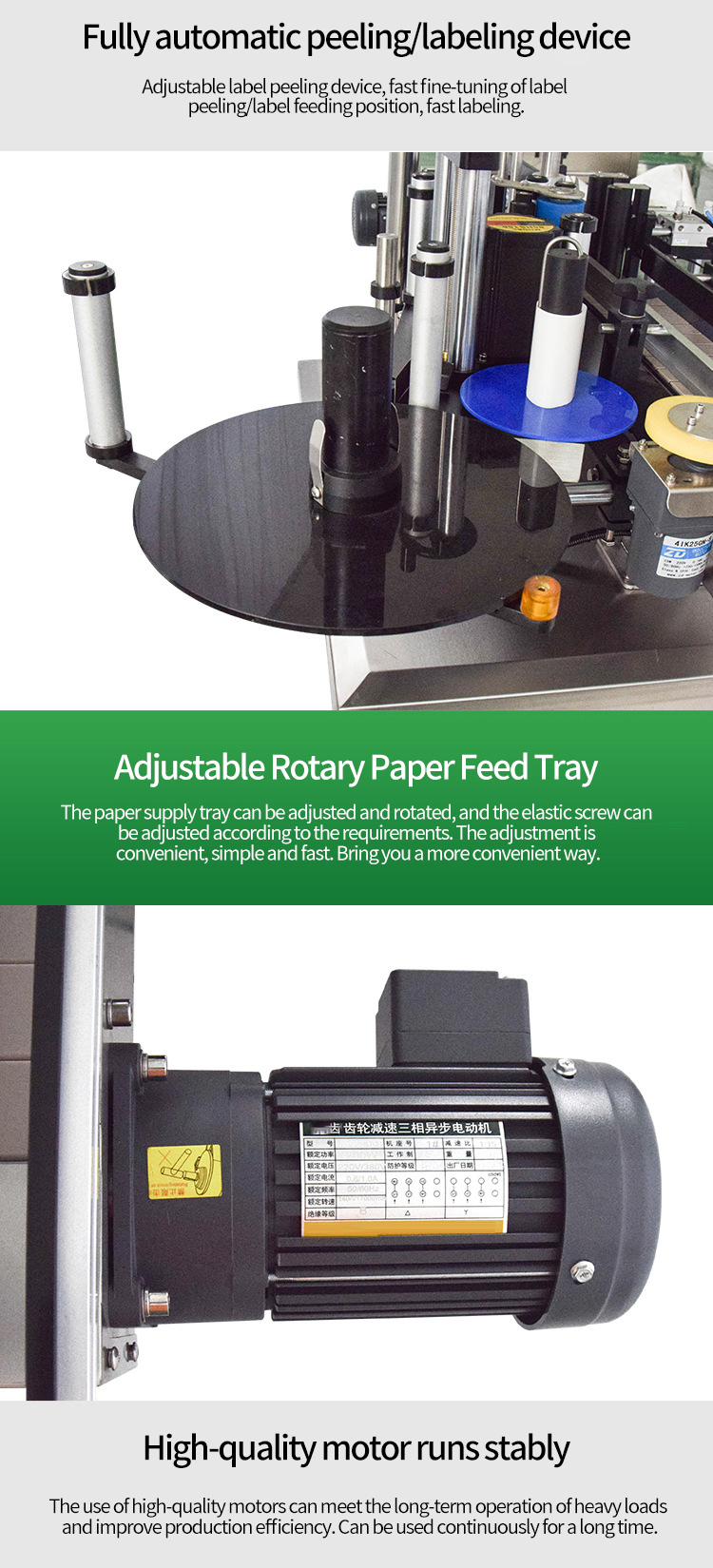

1. With advanced mechanical structure and control system, it can achieve high-speed operation and complete labeling of a large number of products per minute.

2. With good stability and reliability, it can run continuously for a long time, reducing production delays caused by equipment failure or downtime.

3. Equipped with high-precision sensors and positioning systems, it can accurately identify the position and size of the product to ensure that the label is accurately attached to the designated position of the product.

4. Through optimized labeling process and appropriate labeling pressure control, the label can be tightly and flatly attached to the product surface.

5. It realizes fully automated operation from label supply, attachment to product delivery, reducing manual intervention and labor intensity.

The labeling speed of high-speed automatic labeling machines is usually several times or even dozens of times faster than that of traditional labeling machines, which can meet the needs of large-scale production and improve production efficiency.

The use of advanced sensor technology and control systems can achieve high-precision labeling, and the labeling accuracy can generally reach ±0.5mm - ±1mm.

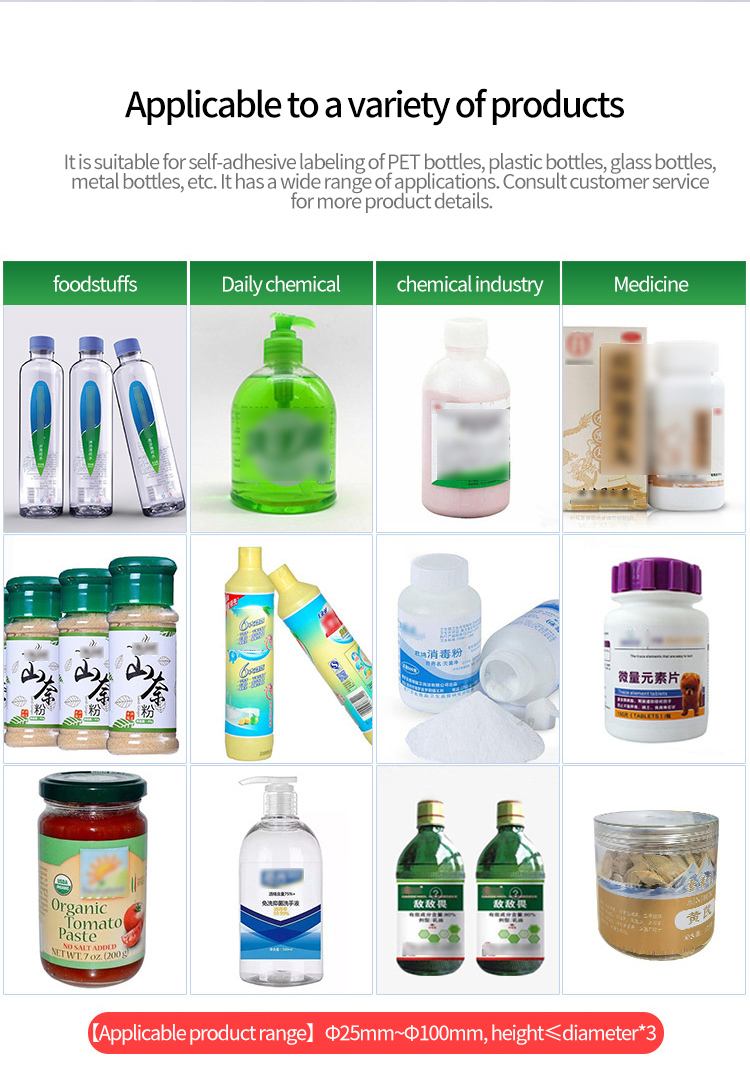

It can adapt to products and labels of different shapes and sizes, whether it is round, square, or oval products, or various specifications of self-adhesive labels, electronic supervision codes, barcodes, etc., it can accurately label them.

The mechanical structure and electrical control system of the equipment have been carefully designed and optimized, which can ensure long-term stable operation, reduce downtime and improve production continuity.

It has the functions of automatic photoelectric tracking, no labeling without object, automatic correction without label, automatic label detection, etc.

It can also realize intelligent management such as production counting, fault alarm, parameter setting protection, etc., reduce manual operation costs and improve production management efficiency.

Safety devices such as safety light curtain, emergency stop button, guardrail, etc. are installed. The safety light curtain can detect when a person enters the dangerous area and immediately stop the equipment; the emergency stop button can quickly cut off the power supply of the equipment in an emergency to protect the safety of personnel and equipment.