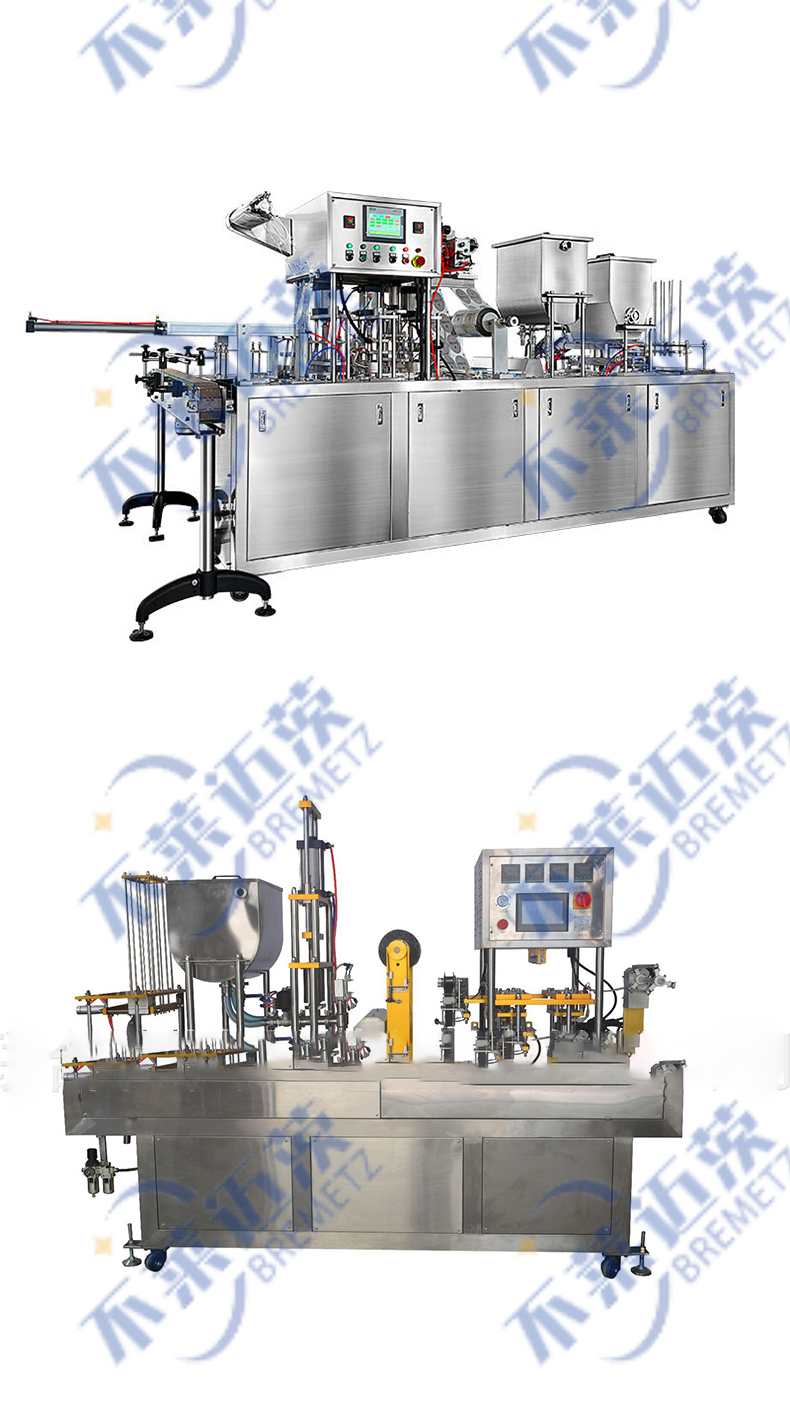

Fully automatic quantitative filling and sealing machine

1. Improve production efficiency: It can automatically complete the quantitative filling and sealing operations of materials without a lot of manual intervention, and can work 24 hours a day.

2. Reduce labor costs: Reduce dependence on manual operation, reduce errors and labor intensity caused by manual operation.

3. Accurately control the filling volume: The use of advanced sensing technology and precise metering system can accurately control the amount of material filled each time to ensure filling accuracy.

4. Stable mechanical structure and performance: The overall structure is reasonably designed, made of high-quality materials and components, and has good stability and durability.

5. Multiple material types: It can handle materials of various forms and properties, and is widely used in multiple industries to meet the diversified production needs of different enterprises.

The fully automatic quantitative filling and sealing machine integrates advanced mechanical technology and intelligent control. The appearance design adheres to the fusion of industrial aesthetics and pragmatism, with a compact overall structure and smooth lines.

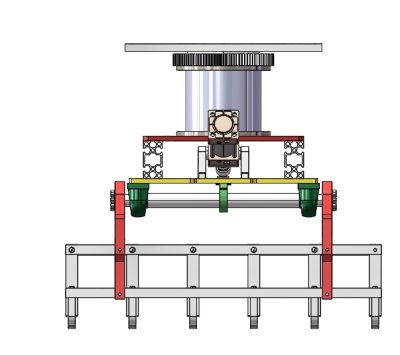

High-precision metering device: For liquid materials, plunger pumps, gear pumps or peristaltic pumps are used with high-precision flow sensors to monitor flow rate and flow in real time. For powder and granular materials, screw meters, vibrating feeders and weighing sensors are used to make fine adjustments based on material density and fluidity.

Heat sealing module: Suitable for thermoplastic packaging materials such as plastic film and aluminum foil. The heating element (such as nickel-chromium alloy heating wire) quickly heats up according to the preset temperature (100-300℃ controllable), and cooperates with the pressure cylinder and silicone heat sealing strip to apply pressure evenly. The sealing width is 5-20 mm, with high strength, leakage prevention and breathability. It is often used for soft food packaging.

Human-machine interaction interface: The touch screen operation panel visually displays the equipment operating parameters and fault alarms. The process parameters can be easily set and the product mode can be switched with a simple tap of the finger. It is easy for novices to use and also has permission management and data record traceability functions.

Precision and efficiency: The filling and sealing accuracy leads the industry, ensuring product quality consistency; the production speed is fast, and the large machine can fill and seal thousands of pieces per hour.

Multi-adaptability: The materials include liquid, powder, granule, paste, and the packaging containers include bottles, cans, bags, and boxes. The materials are compatible with plastics, glass, metal, etc., and can flexibly respond to the complex needs of multiple industries.

Stable and durable: solid mechanical structure, anti-interference electrical system, long life of key components, low operating failure rate, low maintenance cost, ensuring continuous and stable production.

Intelligent and convenient: PLC control has strong automation, easy operation, remote monitoring and data storage to help refine production management and improve operational efficiency.

Widely used in the following fields:

Food and beverage: filling juice, milk, condiments, sealing snacks, quick-frozen foods, preserving freshness and quality.

Medical and health: accurate packaging of medicines, health products, and Chinese medicine preparations, strictly adhering to dosage specifications, and preventing pollution.

Chemical and daily chemical: quantitative bottling of chemical raw materials, exquisite packaging of daily chemical products, convenient for transportation and storage.

Agricultural materials and building materials: accurate packaging of seeds, fertilizers, coatings, etc., to help agricultural harvests and stable building quality.