Fully automatic hand-pressed film roll sealing machine

1. Easy to use: Fully automatic operation mode, just place the film roll and start the machine to automatically complete the sealing process.

2. Fast sealing speed: The advanced transmission system and control technology are adopted to quickly complete the film sealing operation, greatly improving production efficiency.

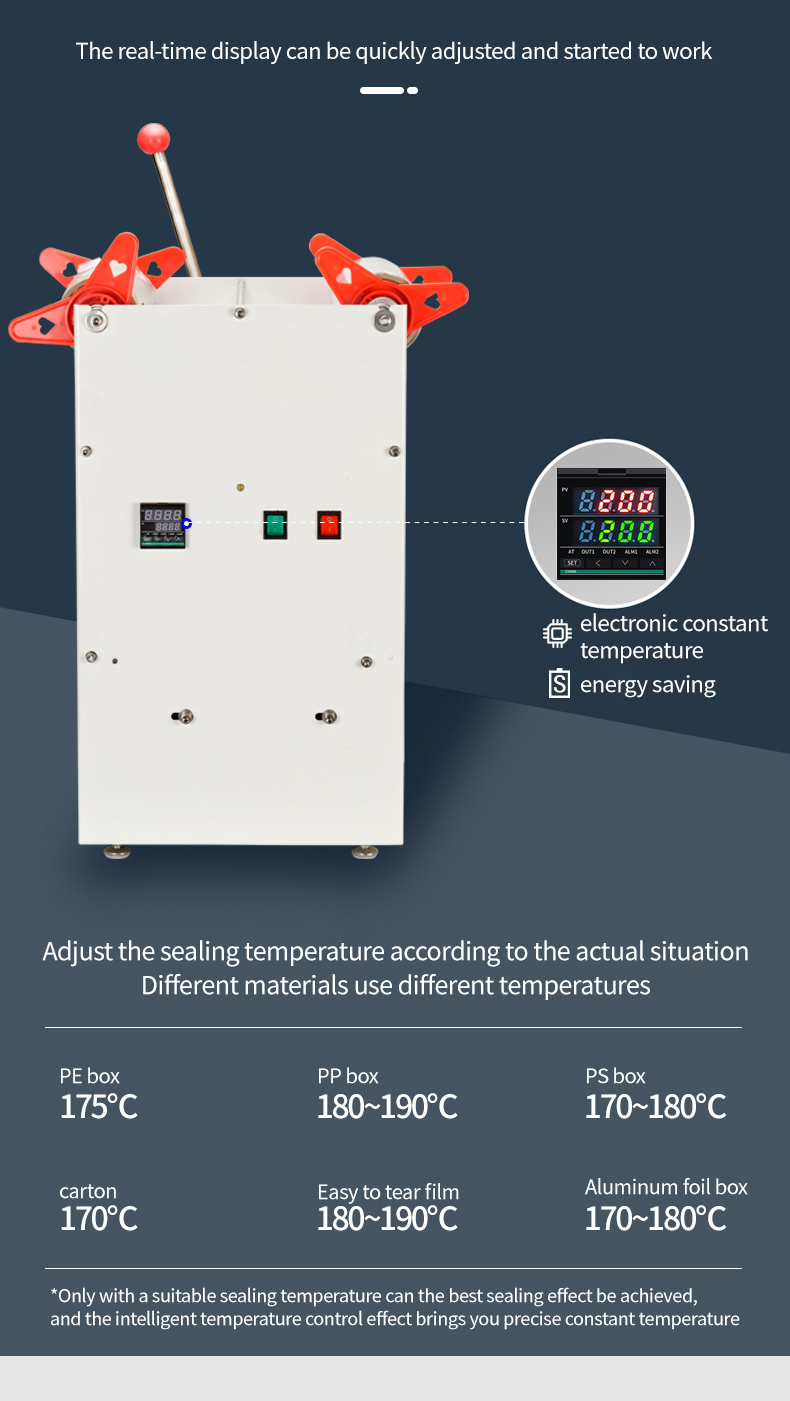

3. Accurate temperature control: Equipped with an electronic constant temperature control system, it can accurately control the sealing temperature to ensure that the film is heated evenly during the sealing process, so that the film at the sealing can be fully melted and firmly bonded together.

4. Stable pressure application: The machine can provide stable and uniform pressure during sealing, ensuring the tightness and flatness of the seal, so that the film thickness at the sealing is consistent.

5. Applicable to packages of different shapes and sizes: By adjusting relevant parameters and replacing some accessories, the machine can adapt to the sealing needs of packages of different shapes and sizes, and can achieve good sealing effects.

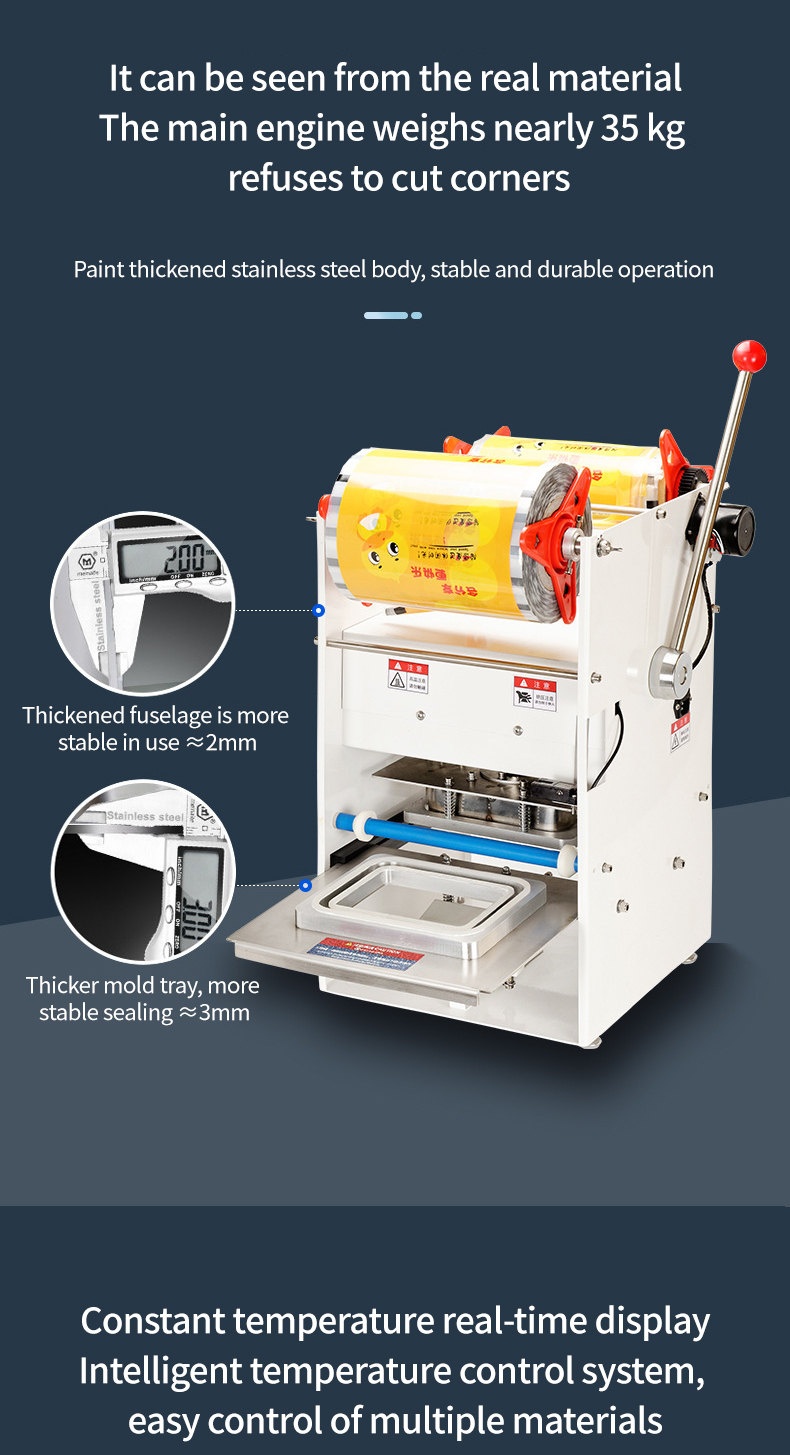

6. Durable parts: Made of high-quality materials and parts, it has high wear resistance, corrosion resistance and service life, reducing the failure rate and maintenance cost of the equipment.

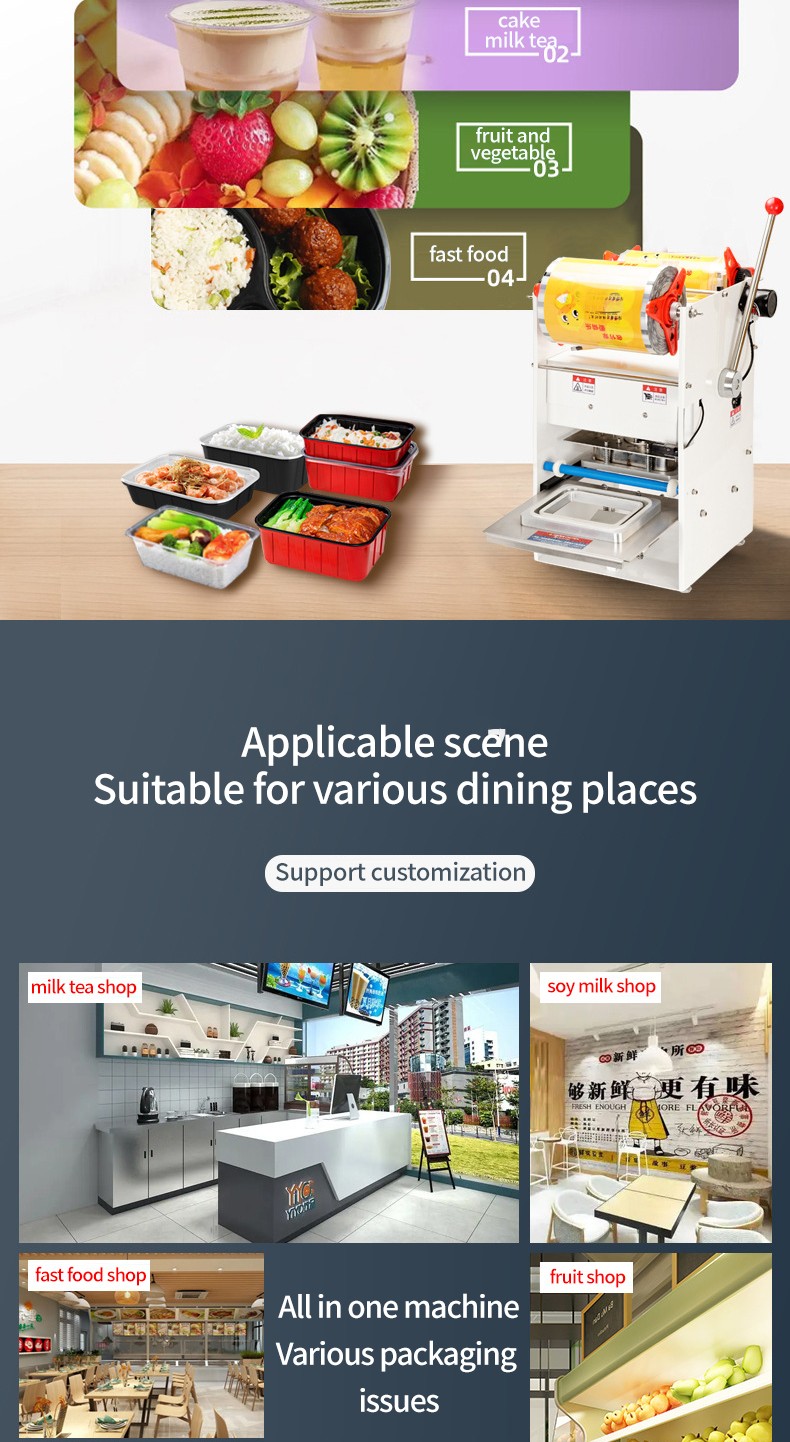

Fully automatic hand-pressed film roll sealing machine is an advanced packaging equipment, which combines automation technology with convenient manual pressing operation, providing an efficient, accurate and reliable solution for film roll sealing operations.

It combines the efficiency of fully automatic operation with the flexibility of manual pressing. During normal production, the equipment can automatically and continuously run according to preset parameters to achieve fast sealing; when encountering special packaging requirements, the operator can accurately control the sealing position and timing through manual pressing to ensure the sealing quality. This unique design enables the equipment to adapt to a wider range of packaging scenarios.

With the help of advanced heating and pressure control technology, high-quality sealing can be achieved. The film at the sealing point melts evenly and fuses tightly, without bubbles, wrinkles or gaps. The sealing strength is high, which can effectively prevent the packaging contents from leaking, getting damp, oxidizing, etc., and extend the shelf life and shelf life of the product. Whether it is for products such as food and medicine that have extremely high requirements for packaging quality, or for hardware, electronics and other products that require moisture-proof and dust-proof packaging, it can provide reliable sealing guarantees.

It has a wide range of adaptability to film materials and packaging sizes. It can handle a variety of film materials, covering various common plastic films and composite films on the market; at the same time, it can adapt to film rolls of different widths and lengths, as well as packages of different shapes and sizes, without the need to frequently replace equipment or accessories, providing companies with a one-stop film roll sealing solution, reducing equipment procurement and operating costs.

Product Name: Semi-automatic Lunch Box Roll Sealing Machine

Product size: 330*450*650mm

Product voltage: 220V/50Hz

Product power: 300~500W

Product net weight:>30kg

Working temperature: 0~300°C

Body material: paint

Sealing time: 600-700 hours

Sealing size: according to the customer's box

The operation panel is concise and clear, and the function buttons are reasonably arranged, so operators can easily set and adjust the operating parameters of the equipment. The equipment can be started and stopped quickly and conveniently, and even personnel without professional training can master the operation method in a short time. In addition, the status information and fault prompts during the operation of the equipment are clear and intuitive, which helps operators to find and solve problems in time, reduce equipment downtime, and improve production efficiency.

It is equipped with complete safety protection devices, including overheat protection, leakage protection, emergency stop button, etc. The overheat protection device can automatically cut off the power supply when the temperature of the heating element is too high, preventing the equipment from being damaged due to overheating, and avoiding safety accidents caused by high temperature; the leakage protection function ensures the personal safety of operators during the use of the equipment; the emergency stop button can quickly stop the operation of the equipment in an emergency to ensure the safety of the equipment and personnel. In addition, the equipment follows strict safety standards during the design and manufacturing process, and uses high-quality materials and components to ensure the overall reliability and stability of the equipment.

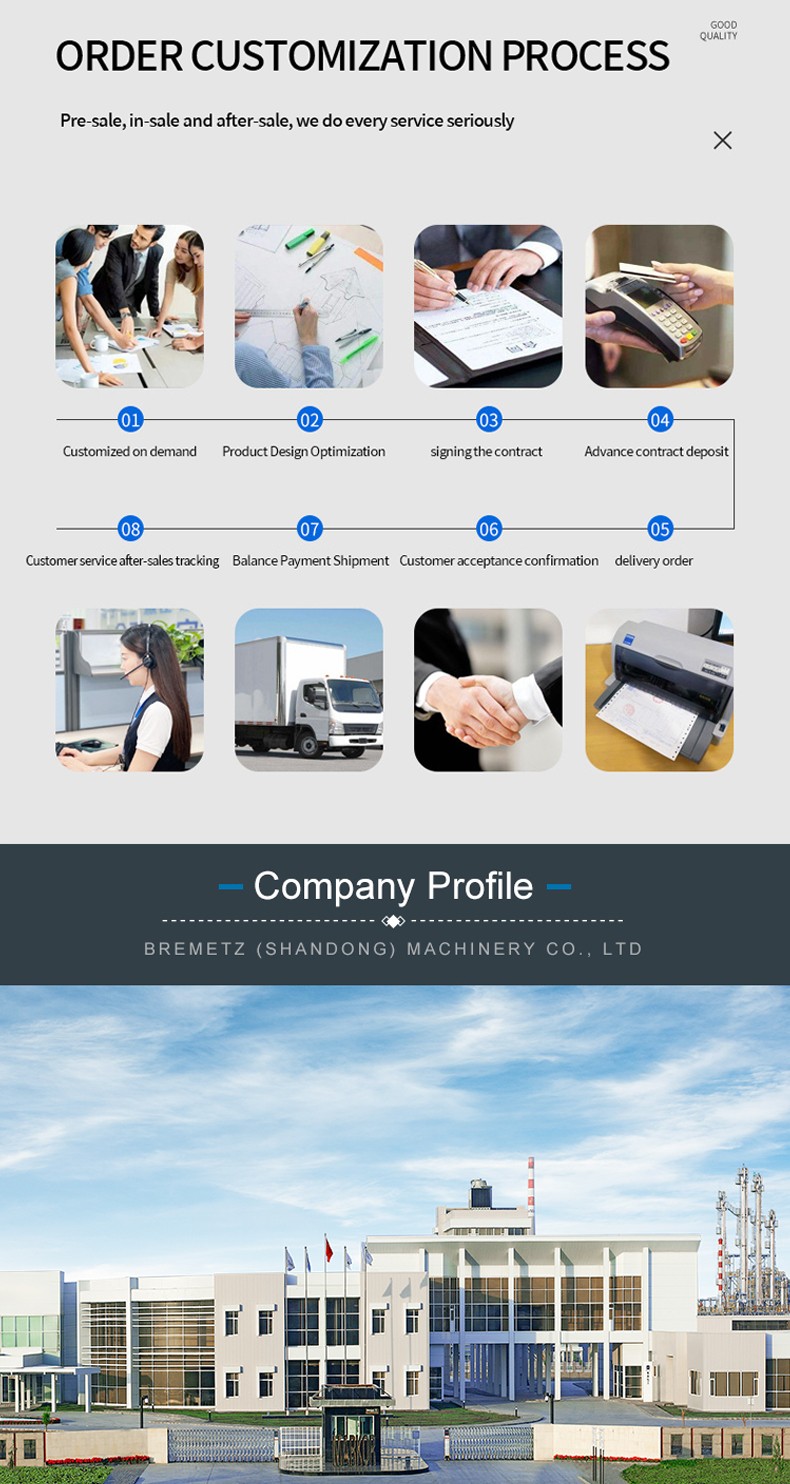

A professional after-sales maintenance team is the key to ensuring the quality of after-sales service. We have a number of experienced and professionally trained after-sales service engineers who can quickly and accurately diagnose and solve various problems.

Online support: Provide users with technical advice and answers through online customer service, email, etc., to help users solve problems encountered during use.

Telephone support: Set up a special after-sales service hotline, users can call at any time when encountering problems, and professional technicians will guide users to operate and troubleshoot over the phone.

Establish a complete spare parts inventory management system to ensure sufficient supply of commonly used spare parts. For some special parts, they can also be allocated or produced in a timely manner to shorten maintenance time.

With the continuous development of technology and changes in user needs, manufacturers will upgrade the control system software of the equipment to provide users with more powerful functions and a more optimized operating experience.