Fully automatic bottle sealing machine

1. High-speed sealing operation: Fully automatic bottle sealing machine has the ability to seal quickly. It adopts advanced transmission system and automatic control technology, and can complete the sealing operation of a large number of bottles per minute.

2. Continuous and stable operation: It can run continuously for a long time. Under a stable working environment, its performance is reliable and will not affect production efficiency due to frequent start and stop.

3. Accurate sealing parameter control: With precise control technology, it can accurately set and adjust key parameters such as sealing temperature, pressure, time, etc.

4. Consistent sealing effect: The sealing quality of each bottle can be highly consistent. The appearance, sealing and firmness of the seal are almost the same.

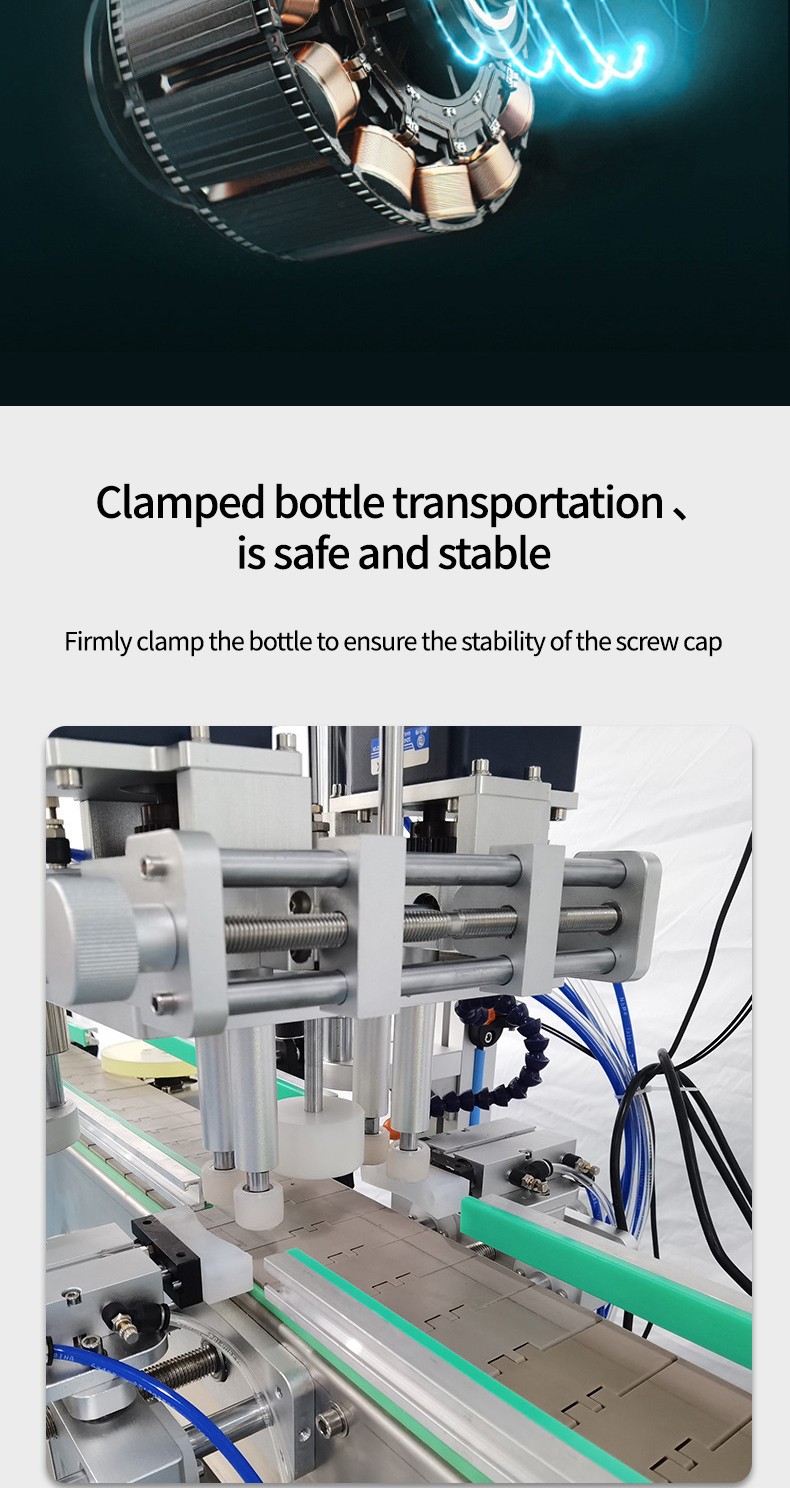

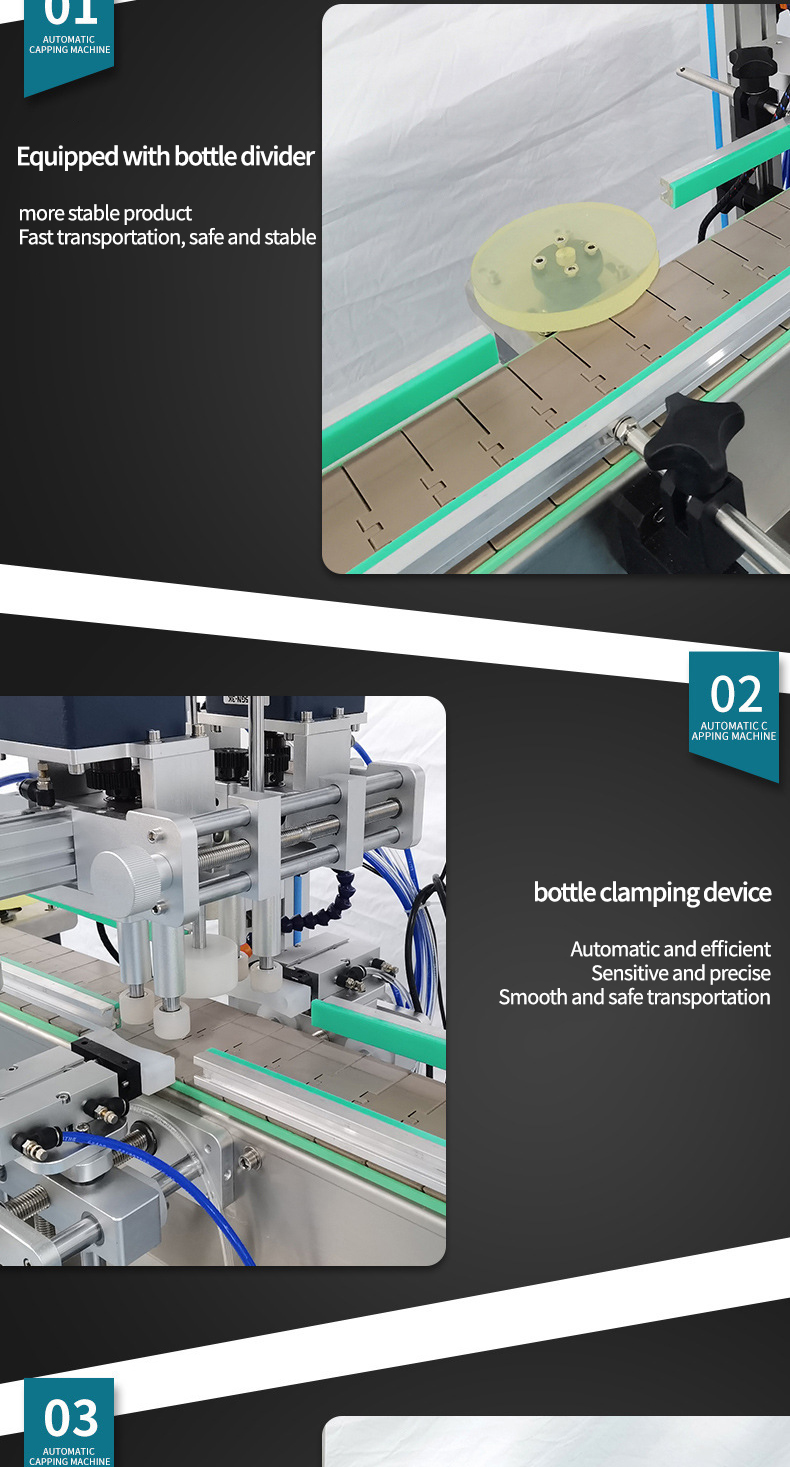

5. Automatic bottle loading and positioning: With automatic bottle loading function, the bottle can be accurately and orderly transported to the sealing station through conveyor belt, robotic arm or other bottle loading device, without manual placement one by one.

6. Automatic detection and feedback: Equipped with a variety of sensors, it can detect the presence of bottles, the installation of bottle caps, and the quality of sealing in real time.

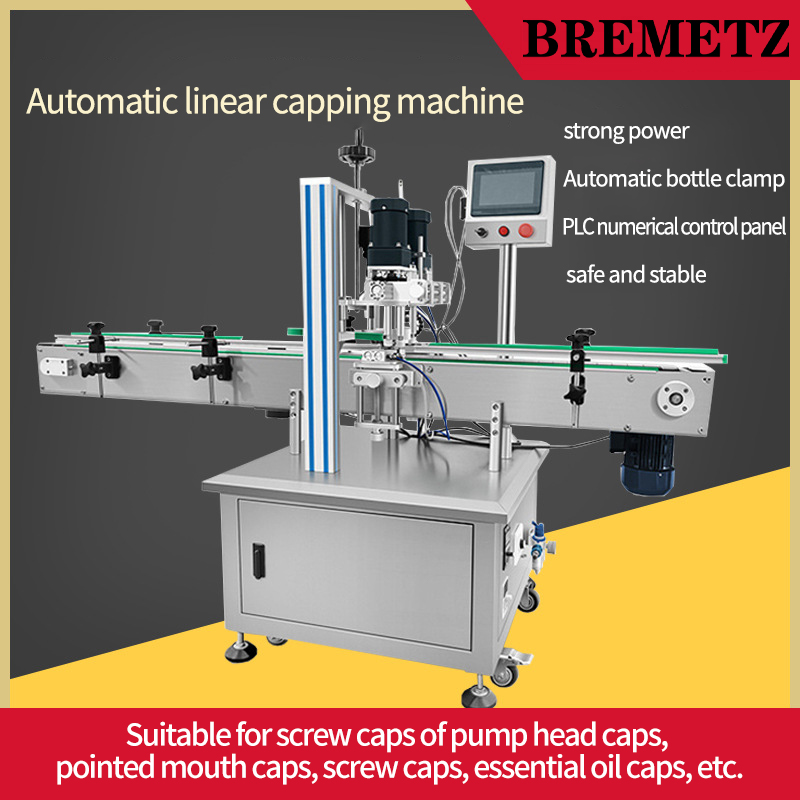

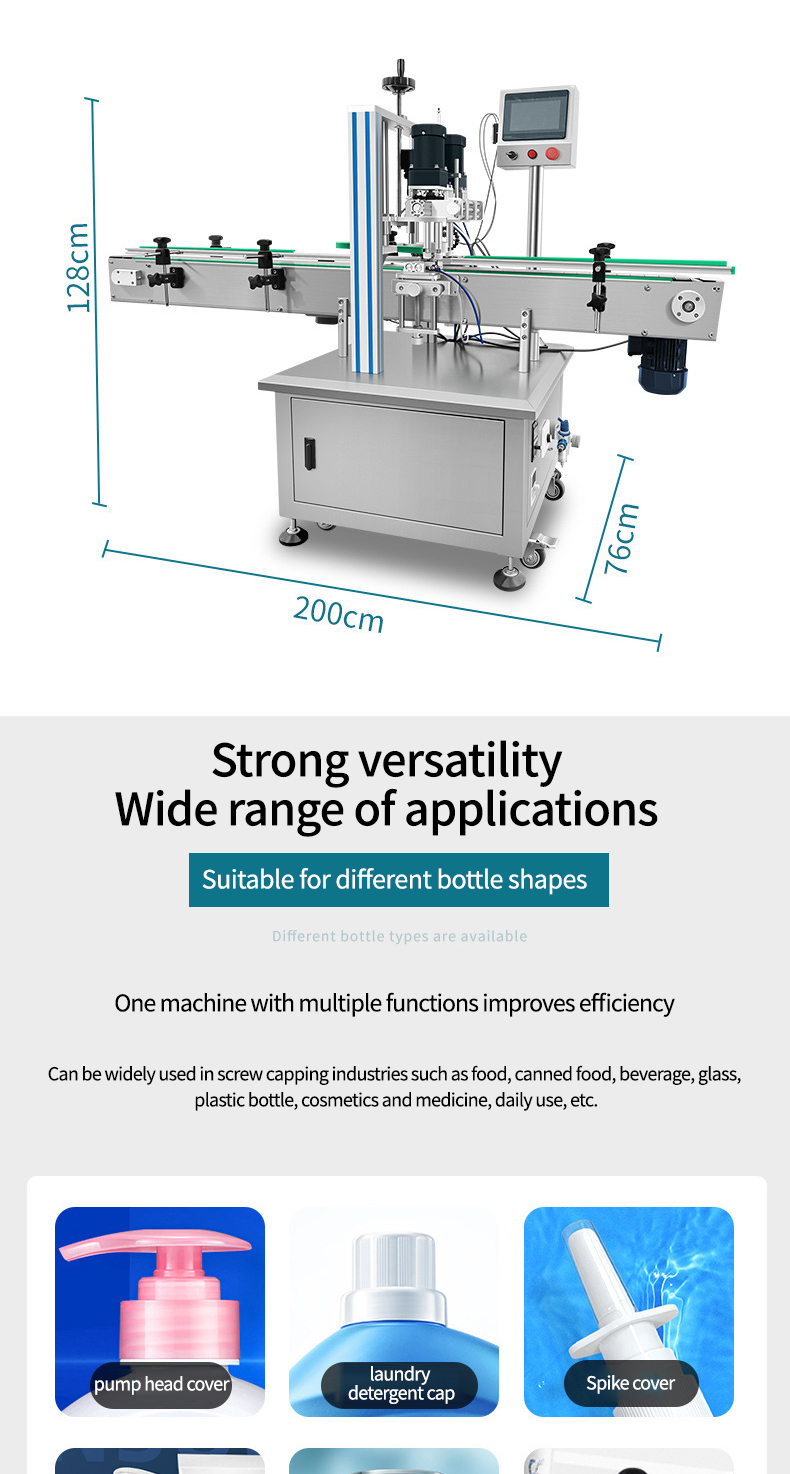

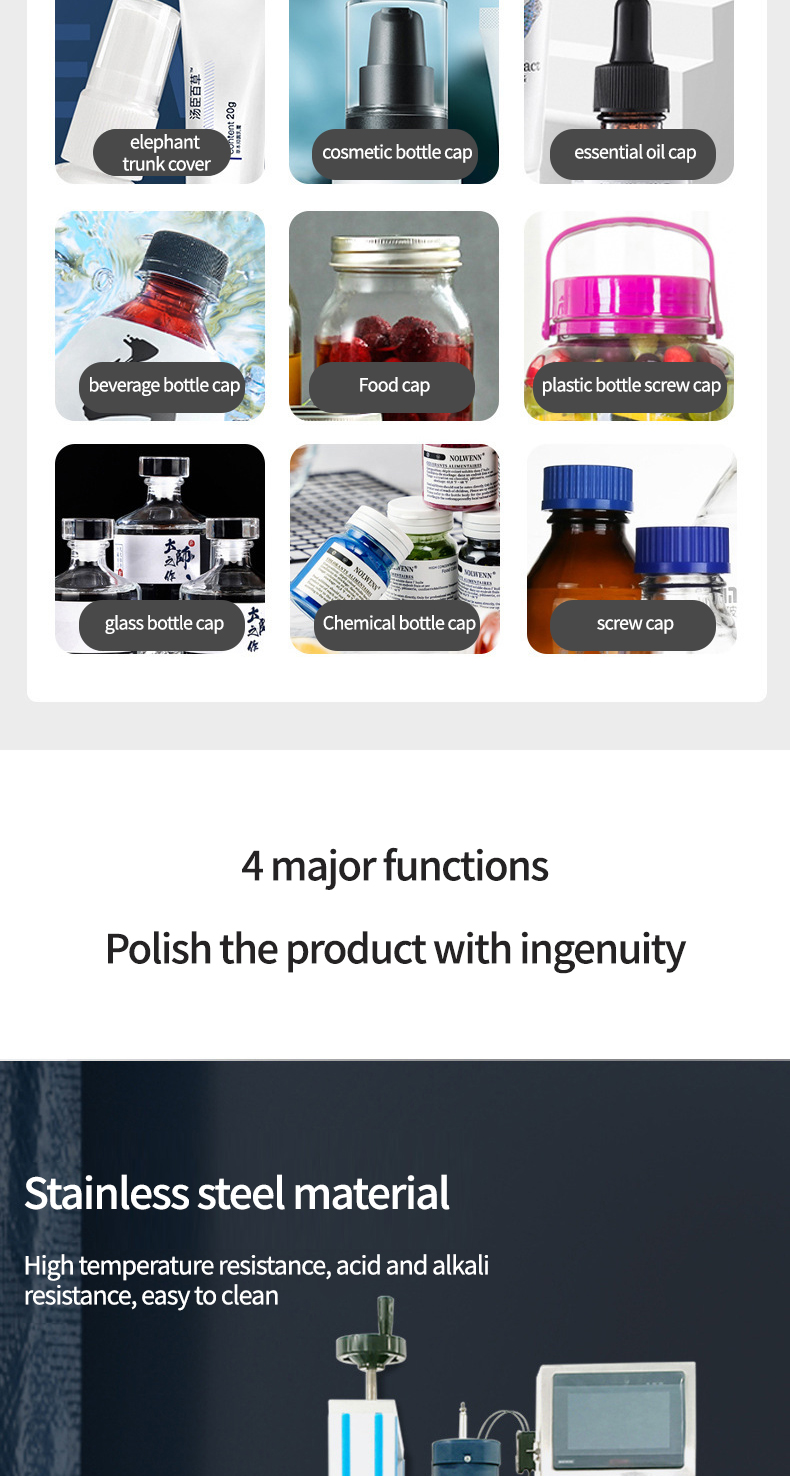

Fully automatic bottle sealing machine is an advanced packaging equipment specially designed for bottled products, aiming to meet the modern industrial production's demand for efficient, accurate and stable bottle sealing operations. It is widely used in many industries such as food, beverage, medicine, cosmetics, etc., and can provide high-quality sealing solutions for bottles of different types and specifications, ensuring the sealing, stability and safety of the products in the bottle, playing a vital role in the entire production process.

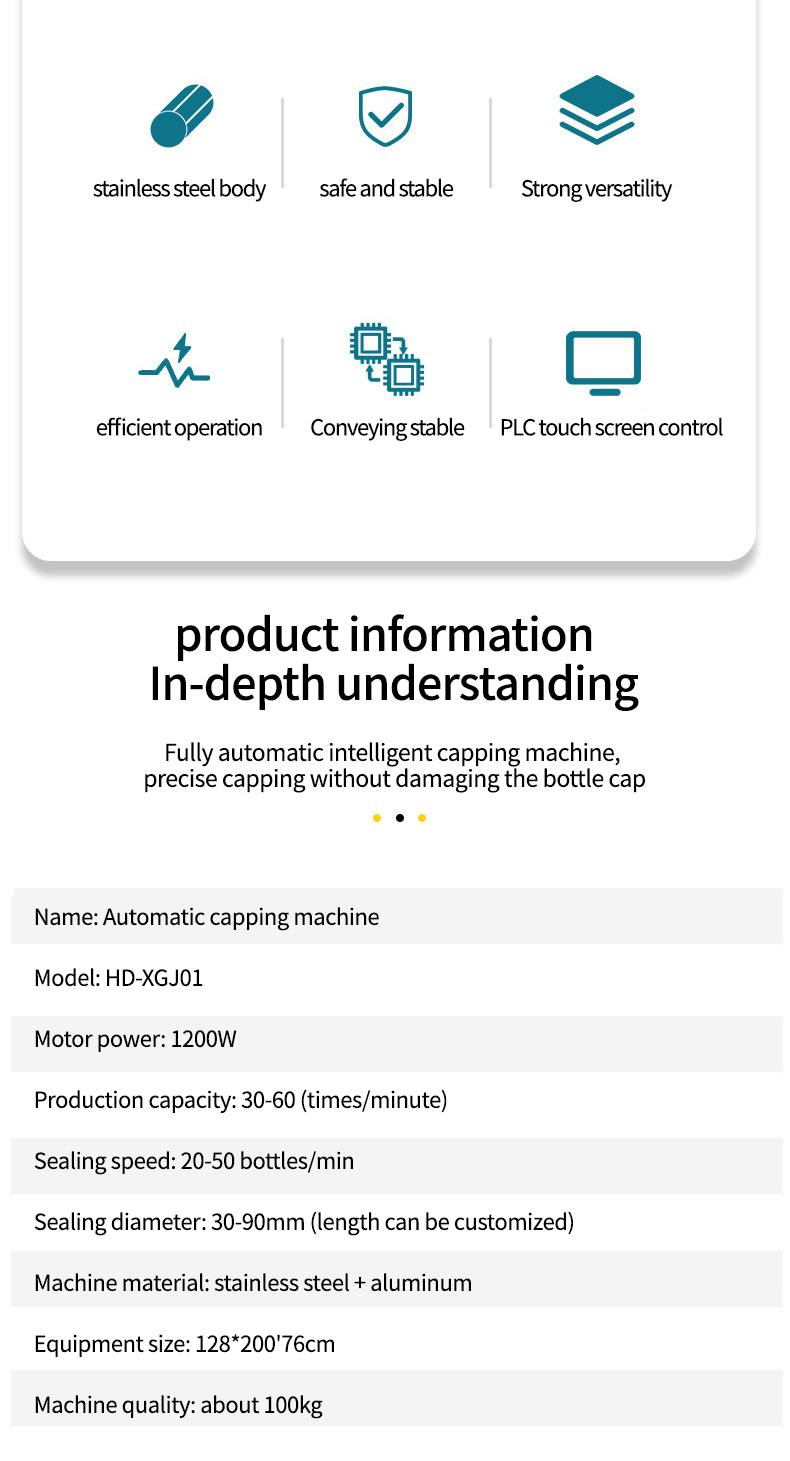

Name: Automatic capping machine

Model: HD-XGJ01

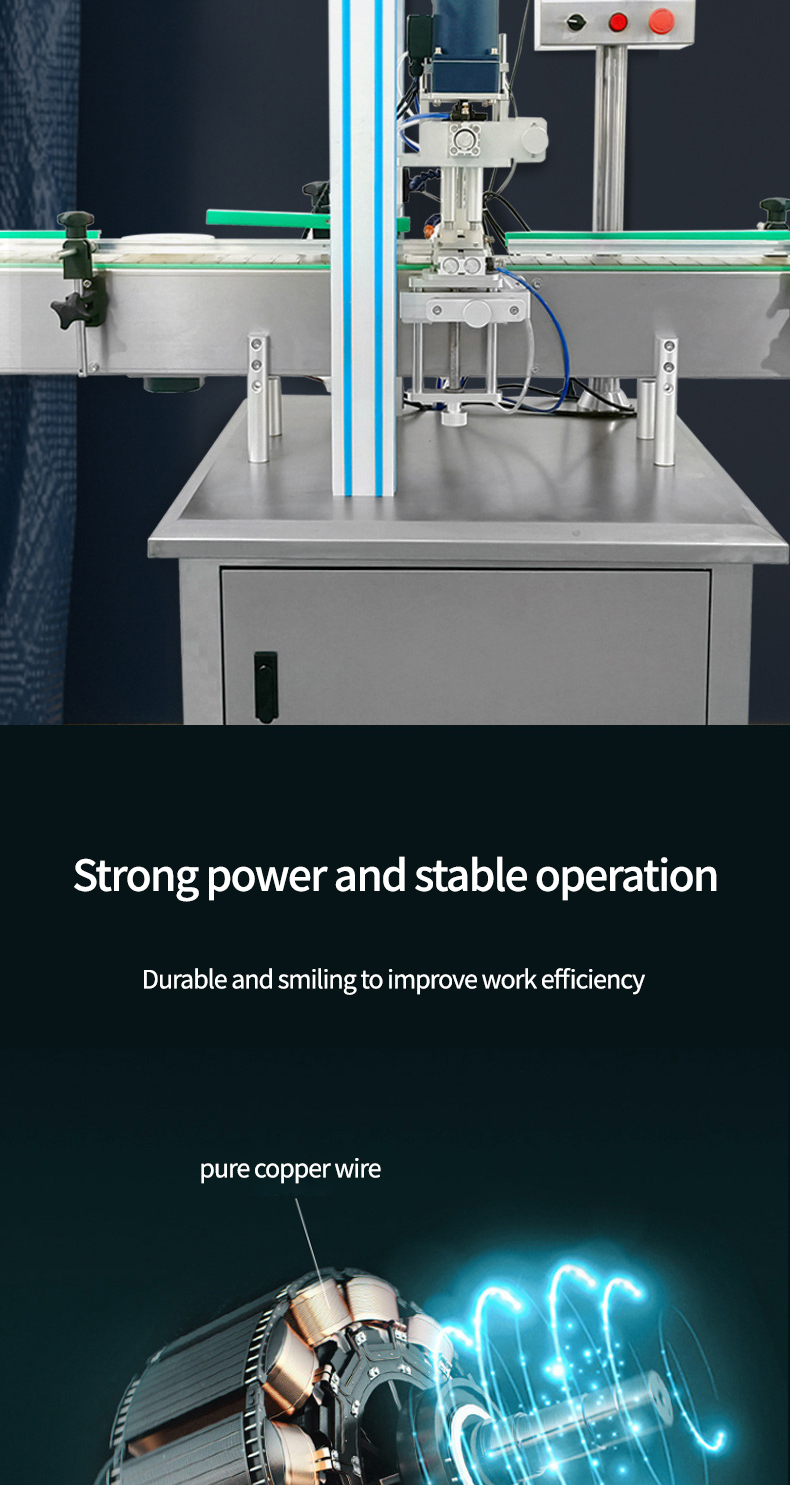

Motor power: 1200W

Production capacity: 30-60 (times/minute)

Sealing speed: 20-50 bottles/min

Sealing diameter: 30-90mm (length can be customized)

Machine material: stainless steel + aluminum

Equipment size: 128*200'76cm

Machine quality: about 100kg

It has strong compatibility with the types and specifications of bottles and caps, and can meet the packaging needs of different industries and different products. Enterprises do not need to configure a variety of sealing equipment for different bottles and caps, which reduces the equipment procurement cost and the complexity of production management, and improves the versatility and use value of the equipment.

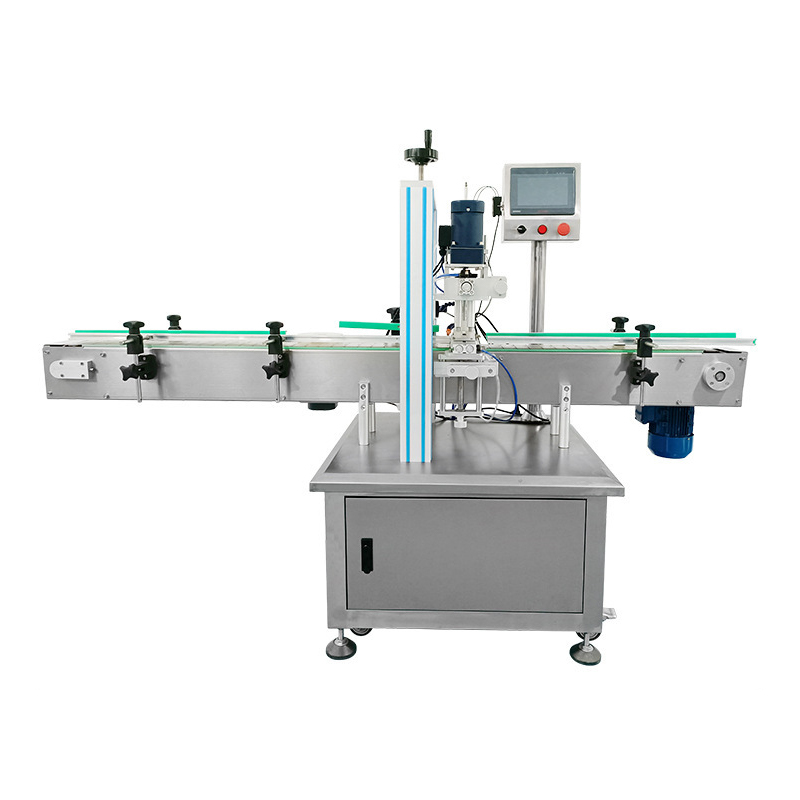

The machine adopts a solid metal structure, such as stainless steel or high-strength aluminum alloy, to ensure the stability and reliability of the equipment during operation. The machine frame is carefully designed to withstand the forces generated by each component during operation, while having good anti-vibration performance to reduce the impact of vibration on the sealing quality.

With its fast sealing speed and continuous and stable operating performance, it can significantly improve production efficiency. In large-scale production lines, it can complete the sealing operation of a large number of bottles in a short time, reduce the production cycle, and meet the enterprise's requirements for output. It is especially suitable for the high-speed production needs of beverage, food and other industries.

Through precise parameter control and advanced sealing technology, we ensure that the sealing quality of each bottle is highly consistent. Whether it is the firmness of the seal, the tightness or the appearance quality, it can meet high standards, effectively protect the quality and safety of the product in the bottle, and reduce product loss and quality accidents caused by sealing problems.

It realizes a fully automated process from bottle conveying, bottle cap supply to sealing operation, reduces manual intervention, reduces labor costs and errors caused by manual operation. The automatic bottle loading, positioning, detection and feedback mechanism ensures the stability and reliability of the production process and improves the intelligence level and production efficiency of the equipment.

The use of food-grade materials and sanitary design ensures that the parts in contact with the product meet the sanitary standards to prevent contamination of the product in the bottle. The perfect safety protection device ensures the personal safety of the operator and the normal operation of the equipment, reduces the probability of safety accidents, and meets the strict requirements of modern production for safety and hygiene.

It is equipped with complete safety protection devices, such as emergency stop button, protective door, overload protection, etc., to ensure the safety of operators during the operation of the equipment. At the same time, the structural design and manufacturing process of the equipment ensure its reliability in the long-term operation process, reduce equipment failures and downtime, and reduce the company's maintenance costs and production losses.

The parts in contact with the bottles and caps are made of food-grade or hygienic materials to avoid contamination of the products in the bottles and meet the strict hygiene requirements of the food, medicine, cosmetics and other industries. In addition, the equipment pays attention to environmental protection during design and operation, such as the use of energy-saving motors and optimized control systems to reduce energy consumption, while also minimizing noise and waste generation.

We have a professional team of installation engineers who have rich experience in installing Fully automatic bottle sealing machine. After the customer purchases the equipment, the installation team will respond quickly and install the equipment according to the customer's production site and equipment layout requirements.

Provide customers with comprehensive operation training courses, including theoretical explanation and on-site practice. The theoretical part covers the basic structure of the equipment, working principle, functions of each system, etc., so that operators can have a deep understanding of the Fully automatic bottle sealing machine.

We develop personalized regular maintenance plans for customers based on factors such as the frequency of use of the equipment and the production environment. Regular maintenance includes cleaning and lubrication of the equipment, checking the wear of parts, calibrating sealing parameters, etc.

We have established multiple customer feedback channels, including customer service hotlines, online customer service platforms, emails, suggestion boxes, etc., to ensure that customers can promptly provide us with any questions, suggestions or comments during the use of the equipment.