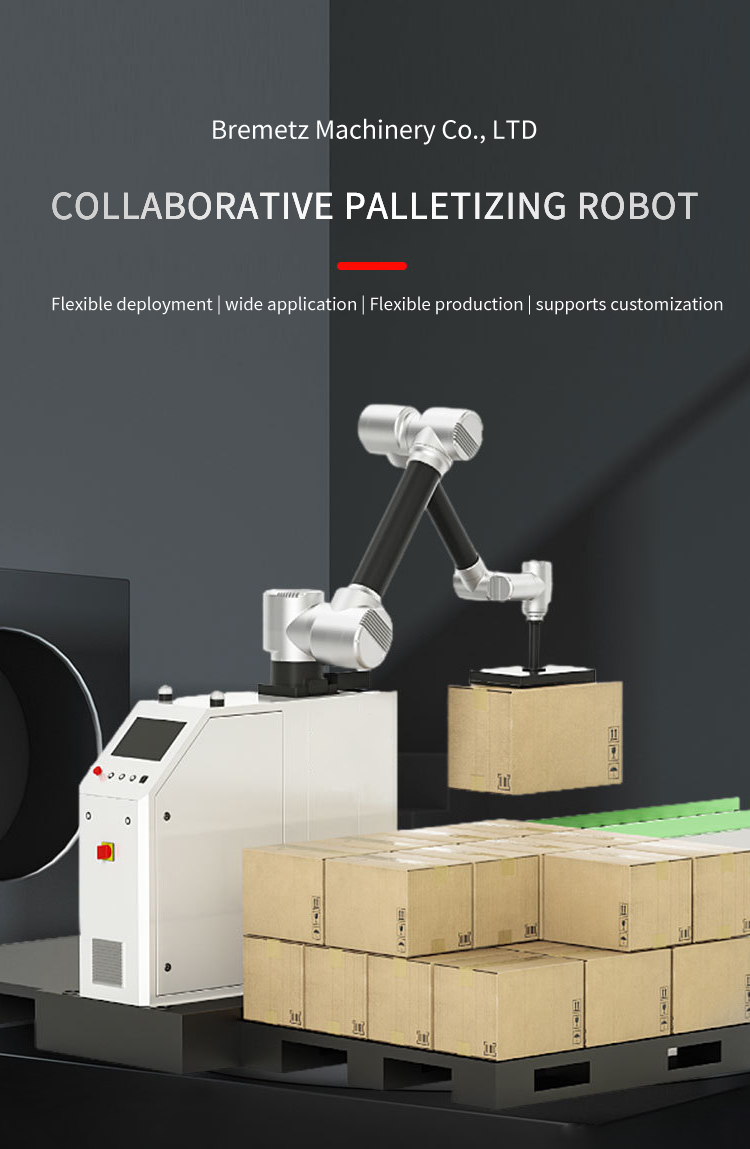

Efficient and intelligent collaborative robots

1. Equipped with safety sensors and advanced collision detection mechanisms, it can stop working immediately once it collides with people or objects.

2. It can sense the surrounding environment in real time, and automatically reduce the running speed or change the movement path when it detects that a person is approaching.

3. It can easily adapt to different production tasks and working environments, and quickly switch between multiple tasks such as handling, assembly, testing, and packaging.

4. It generally has an intuitive programming interface and simple operation method, which lowers the threshold for use and reduces dependence on professional technicians.

5. It has high motion accuracy and high repeated positioning accuracy, and can accurately complete various operation tasks, reducing errors and delays in production.

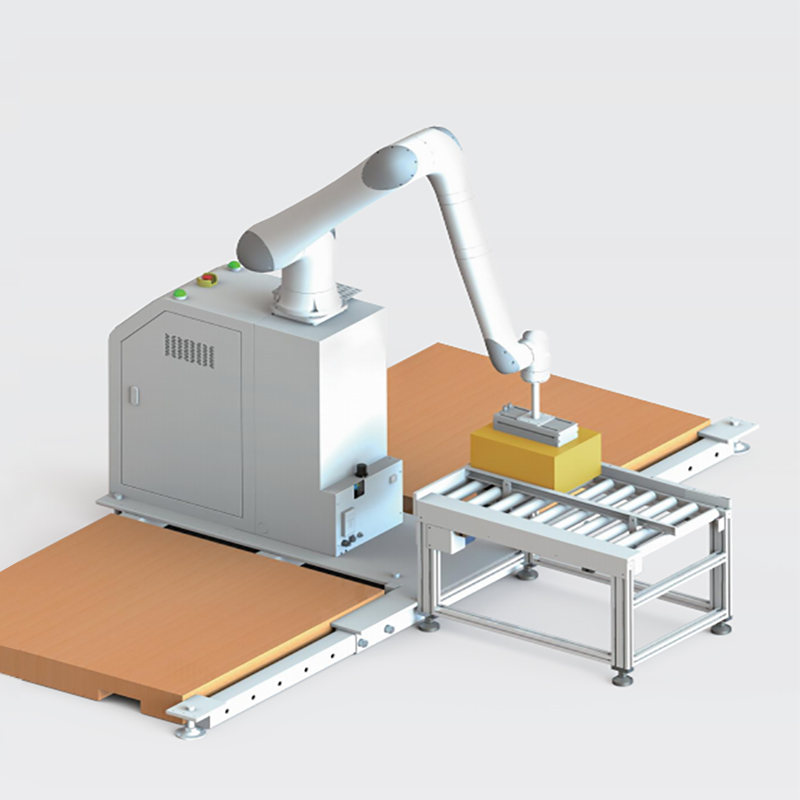

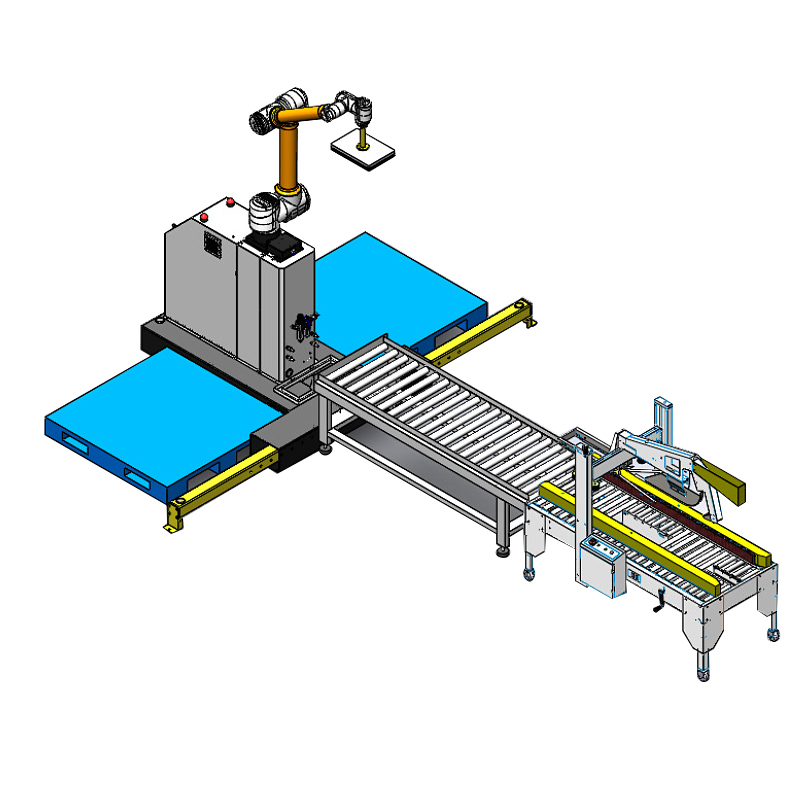

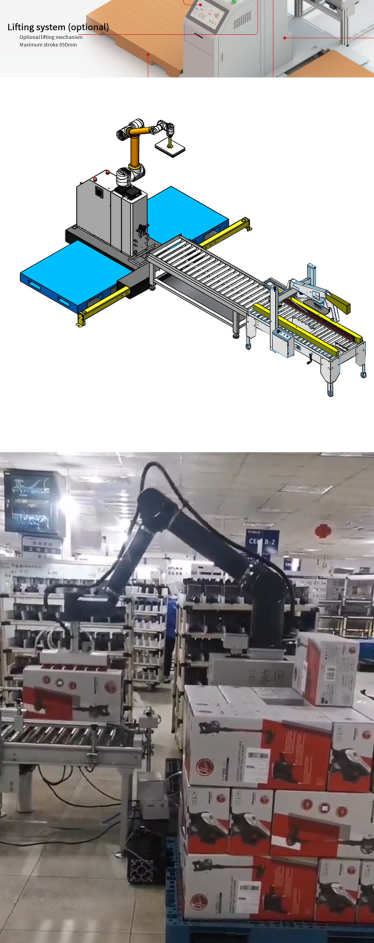

It usually adopts a small and compact design, with a light structure and a small footprint. It can easily adapt to various narrow spaces and complex working environments and can be flexibly deployed in different places such as production lines and warehouses.

It integrates multiple sensors such as cameras, infrared sensors, lidar, etc. to achieve real-time perception of the external environment and accurately obtain information such as the location, shape, and distance of objects.

With the help of advanced visual algorithms and sensor technology, it can perform high-precision identification and positioning of objects of different shapes and materials, and accurately grasp the target objects.

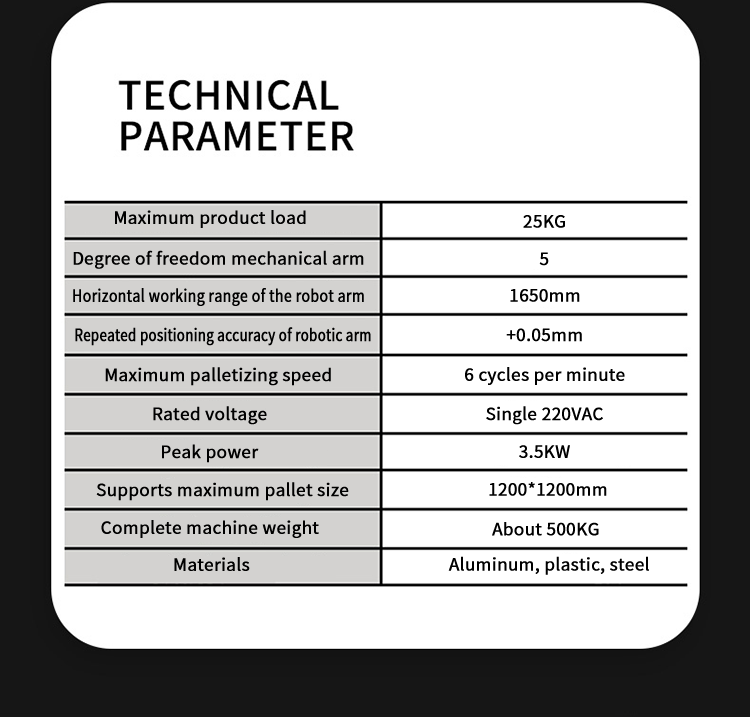

Maximum product load:25KG

Degree of freedom mechanical arm:5

Horizontal working range of the robot arm:1650mm

Repeated positioning accuracy of robotic arm:+0.05mm

Maximum palletizing speed:6 cycles per minute

Rated voltage:Single 220VAC

Peak power:3.5KW

Supports maximum pallet size:1200*1200mm

Complete machine weight:About 500KG

Materials:Aluminum, plastic, steel

By using path planning and trajectory planning technology, you can quickly find the optimal path in a complex environment, avoid obstacles, and complete the task efficiently.

Advanced control algorithms ensure that the robot maintains high speed, high precision and stability during movement, has high repeated positioning accuracy, and can accurately complete various operations.

Connect with the warehouse management system to realize automatic shelving, de-shelfing and inventory of goods, grasp inventory information in real time, and improve the intelligent level of warehouse management.