Fully automatic collaborative robot arm

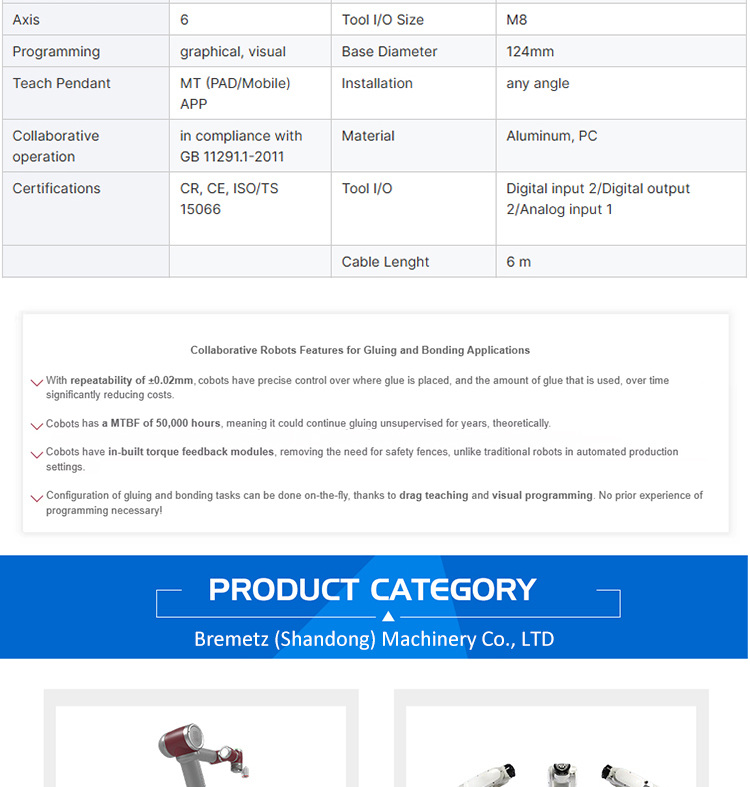

1. It can automatically complete various tasks according to preset programs, and maintain high consistency and accuracy during the operation process.

2. It is equipped with advanced sensor systems, which can perceive the surrounding environment and the location, movement and other information of personnel in real time.

3. It strictly follows relevant safety standards and specifications during the design and manufacturing process, and has complete safety functions and protection mechanisms.

4. Operators can quickly program and debug the robot without professional programming knowledge and skills to adapt it to new production tasks or product changes.

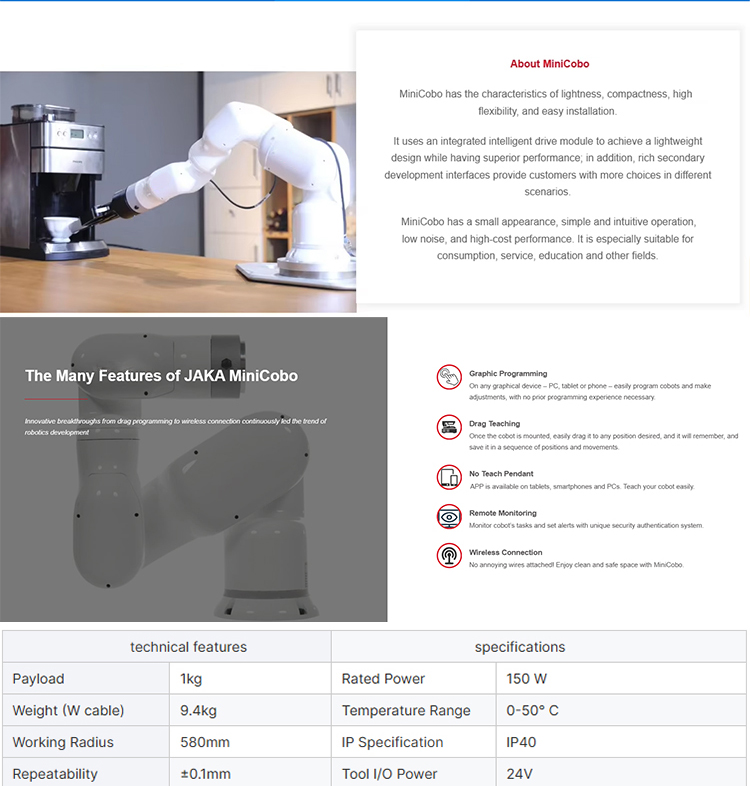

5. The structure is relatively compact and the design is relatively sophisticated, occupying less space in the production workshop or workplace.

The fully automatic collaborative robot arm is an innovative automation device that integrates advanced mechanical design, intelligent control technology and precision sensing system. It is designed for complex tasks in modern industrial production, logistics and warehousing, etc.

It adopts a multi-joint structure, usually with 6 degrees of freedom, and can move flexibly in three-dimensional space, simulating various movements and postures of human arms.

The main body of the robotic arm is made of lightweight and high-strength materials such as aviation aluminum alloy, which effectively reduces its own weight and movement inertia while ensuring that the robotic arm has sufficient rigidity and load-bearing capacity.

The internal structure is compact and reasonable, and the motor, driver, controller, sensor and various cables are highly integrated, reducing the number and complexity of external connection lines.

With industrial-grade dedicated controller as the core, it runs powerful and intelligent robot control software. The control system adopts advanced multi-axis linkage control technology, which can simultaneously perform real-time coordinated control of multiple joints of the robot arm.

The multi-degree-of-freedom design of the robot arm and the quickly replaceable end effector make it highly adaptable to tasks. By replacing different types of end effectors, the robot can easily handle tasks of various shapes, sizes, materials and process requirements.