Explosion-proof spraying handling robot

1. Excellent explosion-proof performance: The shell is made of high-strength explosion-proof material, which can withstand the impact of explosions and prevent dangerous factors such as sparks and high temperatures from spreading to the surrounding environment. This material has been specially treated to have good sealing and corrosion resistance.

2. Reliable gas detection and protection mechanism: Equipped with advanced gas detection sensors, it can monitor the concentration of flammable and explosive gases in the surrounding environment in real time.

3. High-precision spraying technology: Equipped with advanced spraying equipment and control systems, it can achieve precise paint flow control and spraying angle adjustment. Through precise algorithms, the robot can automatically adjust the spraying parameters according to the shape, size and surface requirements of the sprayed object.

4. Multiple spraying modes and material adaptability: Supports multiple spraying modes, such as air spraying, electrostatic spraying, high-pressure airless spraying, etc., which can be flexibly selected according to different paint types and spraying requirements.

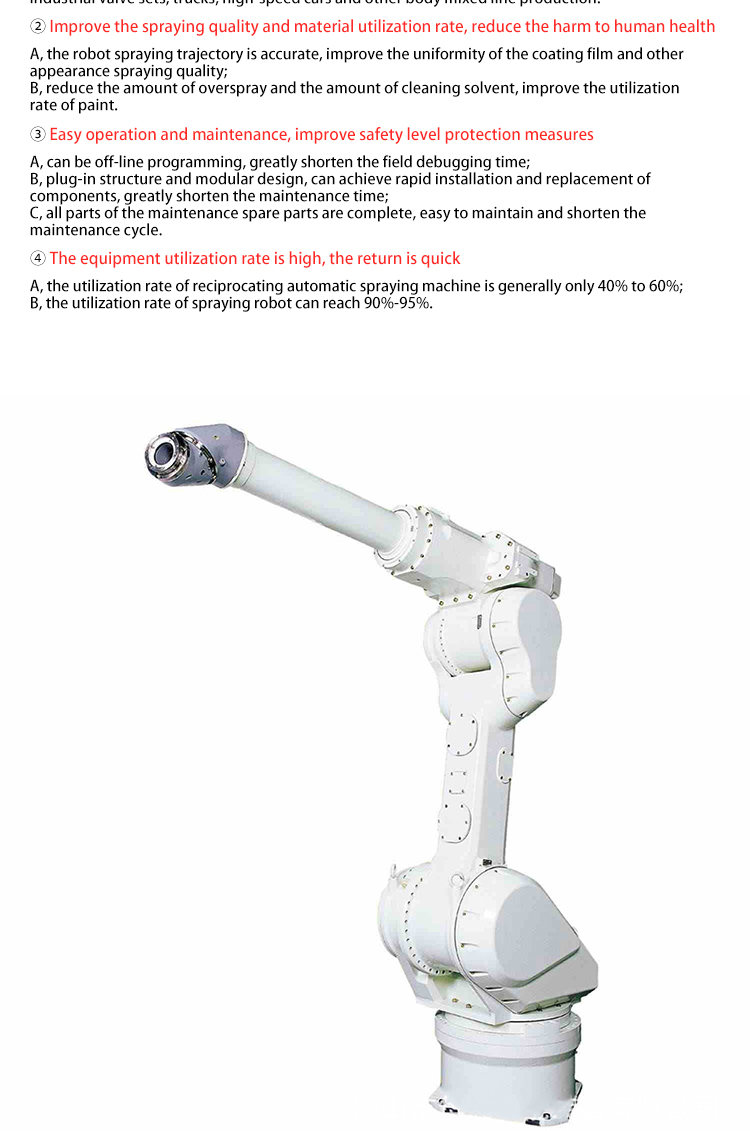

5. Powerful load and flexible motion performance: It has a high load capacity and can easily carry spraying workpieces or materials of different weights and sizes. Its robotic arm and transmission system are specially designed to carry heavier loads while ensuring stable operation, meeting the needs of large-scale cargo handling in industrial production.

6. Intelligent handling path planning: Using advanced path planning algorithms, the robot can automatically plan the optimal handling path according to the layout of the working environment and task requirements. In an environment with obstacles, it can avoid obstacles in real time and choose the fastest and safest route.

7. Safety protection and human-machine collaboration function: In addition to the explosion-proof safety design, the robot is also equipped with a series of safety protection devices. In the process of working with the operator, it automatically adjusts the action or stops running to ensure the safety of personnel.

The explosion-proof spray handling robot is a high-tech automated equipment designed for spraying and handling operations in hazardous environments. It combines advanced explosion-proof technology, precise spraying technology and efficient handling capabilities, and can operate safely and stably in special industrial fields such as petroleum, chemical industry, and military industry where there are flammable and explosive risks, providing reliable protection for the production operations of enterprises.

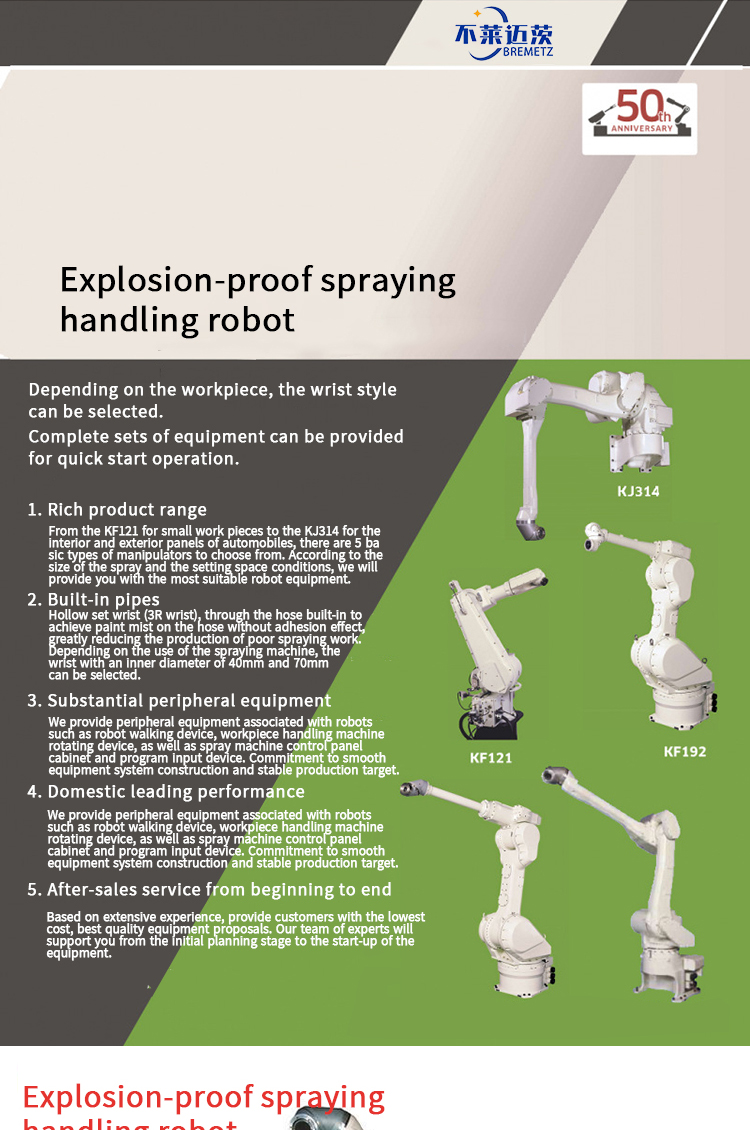

1. Rich product range

According to the size of the spray and the setting space conditions, we will provide you with the most suitable robot equipment.

2. Built-in pipes

Hollow set wrist (3R wrist), through the hose built-in to achieve paint mist on the hose without adhesion effect, greatly reducing the production of poor spraying work.

3. Substantial peripheral equipment

We provide peripheral equipment associated with robots such as robot walking device, workpiece handling machine rotating device, as well as spray machine control panel cabinet and program input device.

4. Domestic leading performance

We provide peripheral equipment associated with robots such as robot walking device, workpiece handling machine rotating device, as well as spray machine control panel cabinet and program input device.

5. After-sales service from beginning to end

Based on extensive experience, provide customers with the lowest cost, best quality equipment proposals.

Explosion-proof structural design: The body shell is made of high-strength, explosion-proof alloy material and processed by special technology. This material has excellent pressure resistance and impact resistance, can effectively resist possible explosion shocks, prevent the splash of debris generated by the explosion, and ensure the safety of the surrounding environment and personnel

Explosion-proof electrical system: The electrical system is strictly designed in accordance with international explosion-proof standards. All circuit wiring uses fire-proof and explosion-proof cables, and the connection between the cables uses special sealing joints to ensure that no electric sparks sufficient to cause an explosion will be generated during normal operation and fault conditions.

Gas monitoring and alarm system: Equipped with high-precision and high-sensitivity combustible gas and explosive gas monitoring sensors. These sensors can monitor the gas concentration in the robot's surrounding environment in real time and continuously, and transmit data to the control system. When the gas concentration is detected to reach the preset dangerous threshold, the robot will automatically trigger the alarm system and send out a strong sound and light alarm signal.

Advanced spraying technology: It adopts a combination of advanced electrostatic spraying technology and air-assisted spraying technology. Electrostatic spraying can make the paint particles better adsorbed on the surface of the sprayed object under the action of the electric field, improving the adhesion and coverage of the paint. Air-assisted spraying can further refine the paint particles, making the spraying effect more uniform and smooth.

Intelligent spraying control system: It integrates an intelligent visual recognition system, which can quickly and accurately scan and identify the sprayed object in three dimensions. It supports the preset and adjustment of multiple spraying modes and parameters. Users can easily set the spraying mode on the operation interface according to different paint types, materials of the sprayed objects and spraying requirements, such as automatic mode, manual mode, fixed-point spraying mode, etc.

High-load and flexible robotic arm: It has a strong load capacity. The robotic arm design adopts high-strength lightweight alloy materials and advanced transmission structure, which can withstand heavier loads.