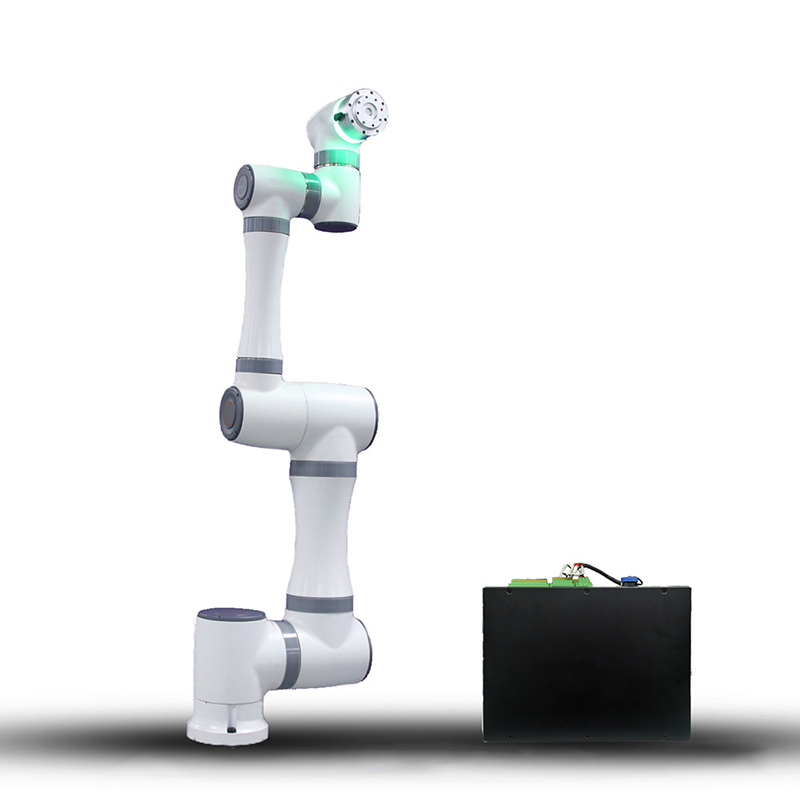

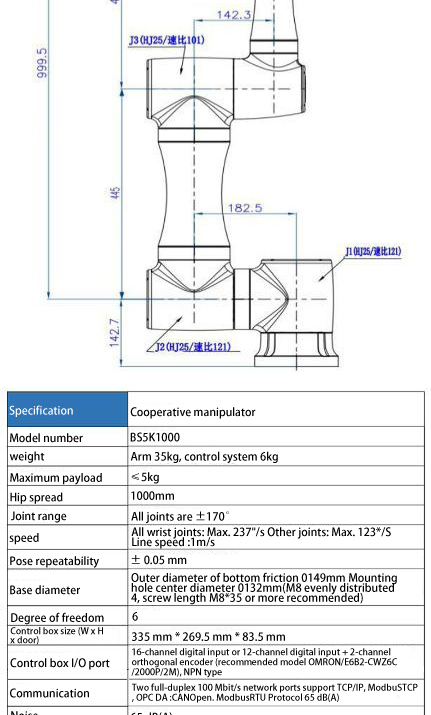

Intelligent collaborative robot arm

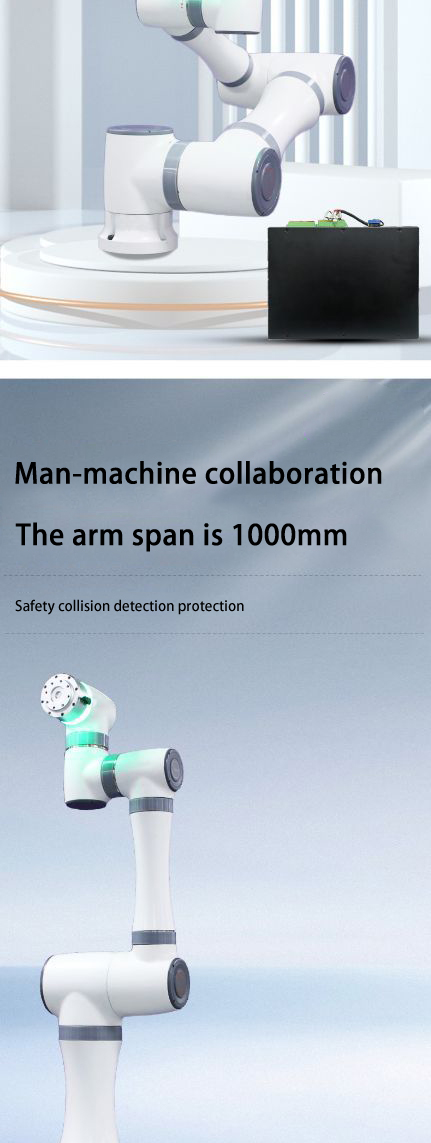

1. Equipped with high-precision force sensors, it can sense the contact force with the human body or other objects in real time. .

2. The surface of the robot arm is smooth, without sharp edges and gaps, and the joints are rounded to reduce the risk of operators being pinched or scratched during contact.

3. It usually has multiple degrees of freedom, can achieve complex and diverse motion trajectories in three-dimensional space, and can flexibly reach different positions and angles.

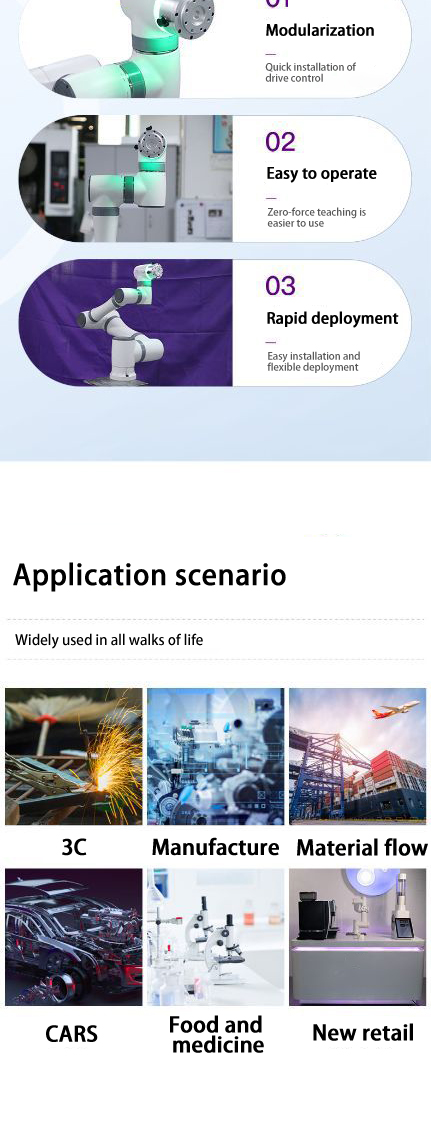

4. It uses lightweight materials and compact design, has a light weight, and is easy to move and install. It can be quickly deployed in different work scenarios.

5. Supports teaching programming mode. The operator can manually drag the robot arm to the target position and posture, record the motion trajectory and action parameters, and the robot arm can automatically reproduce the operation process.

The intelligent collaborative robot arm is an innovative industrial equipment that integrates advanced artificial intelligence technology, precision mechanical design, multimodal sensing and efficient human-computer interaction functions.

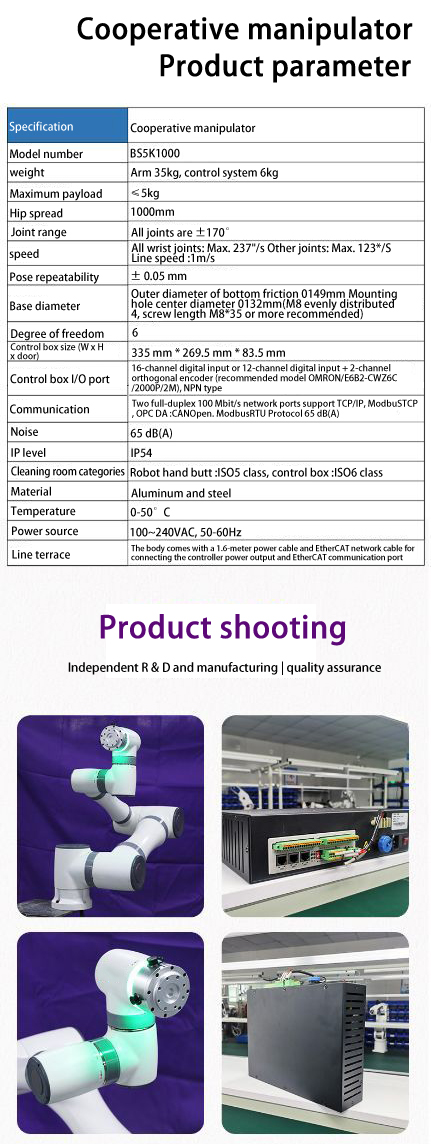

Made of lightweight and strong materials such as high-strength aluminum alloy or carbon fiber, the robotic arm has good rigidity while its weight is effectively controlled, thus achieving fast and flexible movement response.

It is equipped with a rich variety of quickly replaceable end effectors to adapt to various complex task scenarios.For the grasping and operation of tiny parts, it is equipped with high-precision pneumatic grippers or electric grippers, and the gripper fingers are made of special flexible materials and adaptive design.

A comprehensive and advanced sensing system is integrated to provide key support for intelligent collaboration and high-precision operation. Force sensors are widely distributed in the joints and end effectors of the robot arm to monitor the force and torque information of the robot arm during movement and operation in real time.

With a high-performance multi-axis motion controller as the core, it runs intelligent control algorithms optimized for intelligent collaboration and high-precision operation. At the same time, the control system also supports a variety of communication protocols and interfaces.

The use of advanced deep learning algorithms and computer vision technology enables the robot to intelligently perceive and understand complex working environments and operating objects.

Based on reinforcement learning algorithms and machine learning models, the robot arm can make autonomous decisions and select the optimal operation strategy in different task scenarios.

An advanced compliant control algorithm has been developed to enable the robotic arm to exhibit compliance and flexibility similar to that of a human arm when interacting with the external environment.

It can be widely used in different production links of multiple industries, such as electronic manufacturing, automobile manufacturing, equipment, logistics warehousing, education and scientific research, and can adapt to various types of work tasks and production environment requirements.