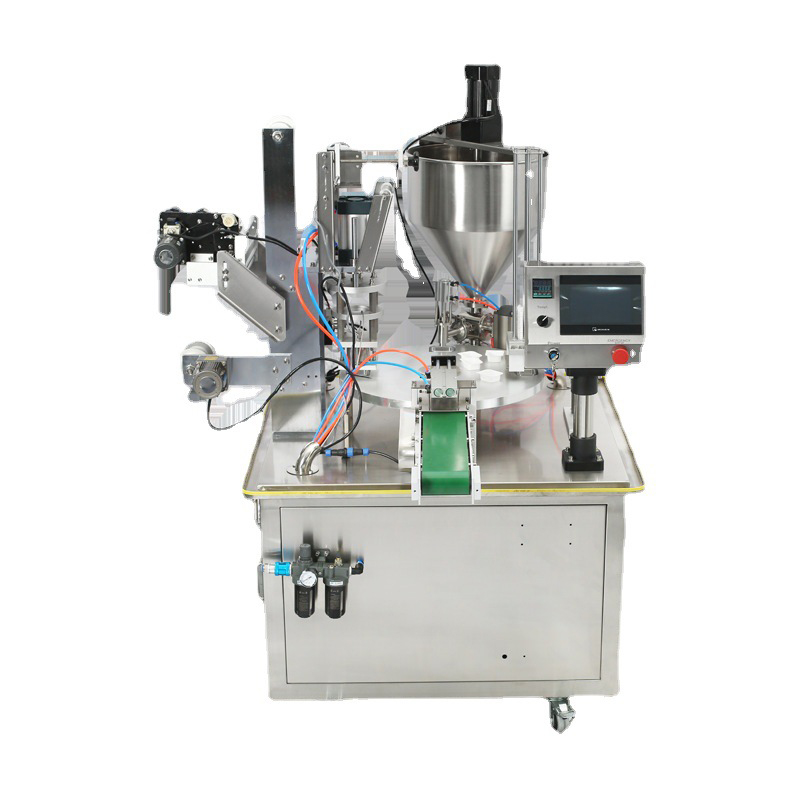

Automatic rotary plate filling and sealing machine

1. High speed: The machine adopts a rotary design, which can realize continuous filling and sealing operations with extremely high production efficiency.

2. Multifunctional integration: It integrates multiple functions such as automatic cup dropping, filling, sealing, film cutting, film collection and cup discharging, which reduces the equipment footprint.

3. High filling accuracy: Through advanced metering devices and control systems, the filling volume can be accurately controlled to ensure that the material filling volume in each container is consistent.

4. Good sealing quality: Using constant temperature hot pressing sealing technology, parameters such as sealing temperature, pressure and time can be accurately adjusted.

5. Applicable to a variety of containers: Equipped with different molds and accessories, it can be applied to packaging containers of various shapes and specifications, such as plastic cups, plastic boxes, cans, etc.

6. Stable operation guarantee: The mechanical structure is sturdy and durable, the electrical system is stable and reliable, and it has undergone strict quality inspection and debugging.

The automatic rotary plate filling and sealing machine uses a rotating disc structure to transport the containers to be filled and sealed to each work station in sequence. At the filling station, the precise metering device injects the material into the container according to the preset amount; then, at the sealing station, the filled container is sealed using appropriate sealing technologies such as heat sealing and pressure sealing to complete the entire packaging process.

High production efficiency: The rotary design enables the equipment to perform filling and sealing operations continuously, greatly improving the production speed, meeting the needs of large-scale production, and effectively improving the company's production capacity.

High filling accuracy: Equipped with a high-precision metering device, it can accurately control the filling volume with a very small error range, ensuring the stability and consistency of product quality and reducing material waste.

Wide range of applications: It can adapt to various types of containers and materials. By replacing different filling heads, sealing molds and other accessories, it can fill and seal plastic cups, plastic bottles, cans and other containers of different shapes and specifications. It can also handle various forms of materials such as liquids, pastes, powders, and particles. It is widely used in many industries such as food, beverages, medicine, and daily chemicals.

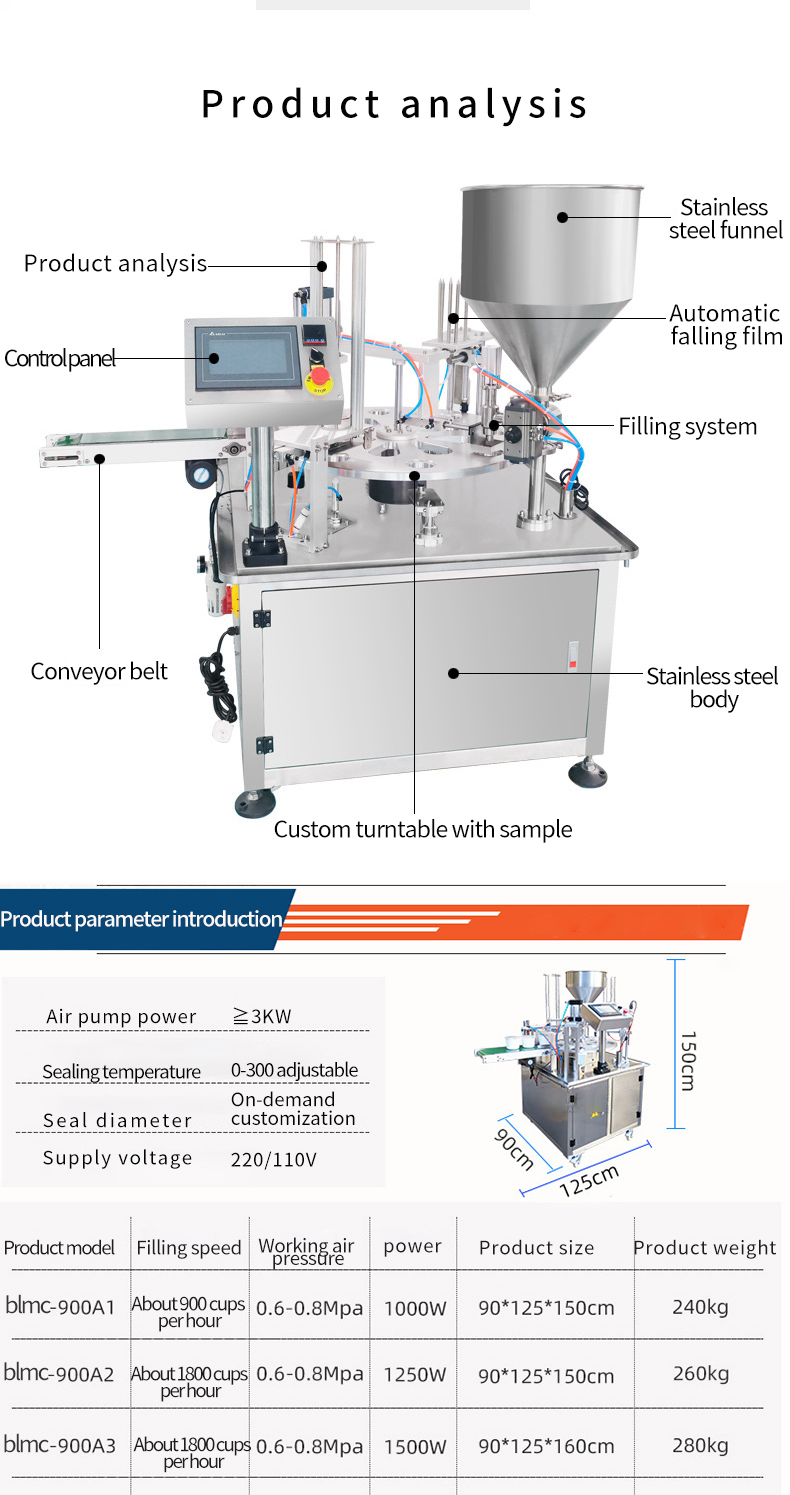

Product parameter introduction:

Air pump power:≥3KW

Sealing temperature:0-300 adjustable

Seal diameter:On-demand customization

Supply voltage:220/110V

Product model:blmc-900A1,blmc-900A2,blmc-900A3

Filling speed:About 900 cups per hour,About 1800 cups perhour our,About 1800 cups perhour our

Working air pressure:0.6-0.8Mpa,0.6-0.8Mpa,0.6-0.8Mpa

power:1000W,1250W,1500W

Product size:90*125*150cm,90*125*150cm,90*125*160cm

Product weight:240kg,260kg,280kg

Easy to operate: PLC control system and touch screen operation interface make the operation simpler, more intuitive and easy to use. Operators only need simple training to master the operation of the equipment, which reduces the requirements for professional skills of operators.

Easy maintenance: The equipment has a reasonable structural design, is easy to disassemble and clean, and is convenient for daily maintenance. At the same time, key components are made of high-quality materials and imported components, with stable and reliable performance and long service life, reducing the cost of equipment maintenance and replacement.