Intelligent and efficient strapping machine

1. Fast operation: Able to complete a large amount of packaging work in a short time, significantly increasing the speed of production and packaging.

2. Strong continuous working ability: It can operate stably for a long time without frequent downtime, rest or maintenance, which greatly increases the work output per unit time.

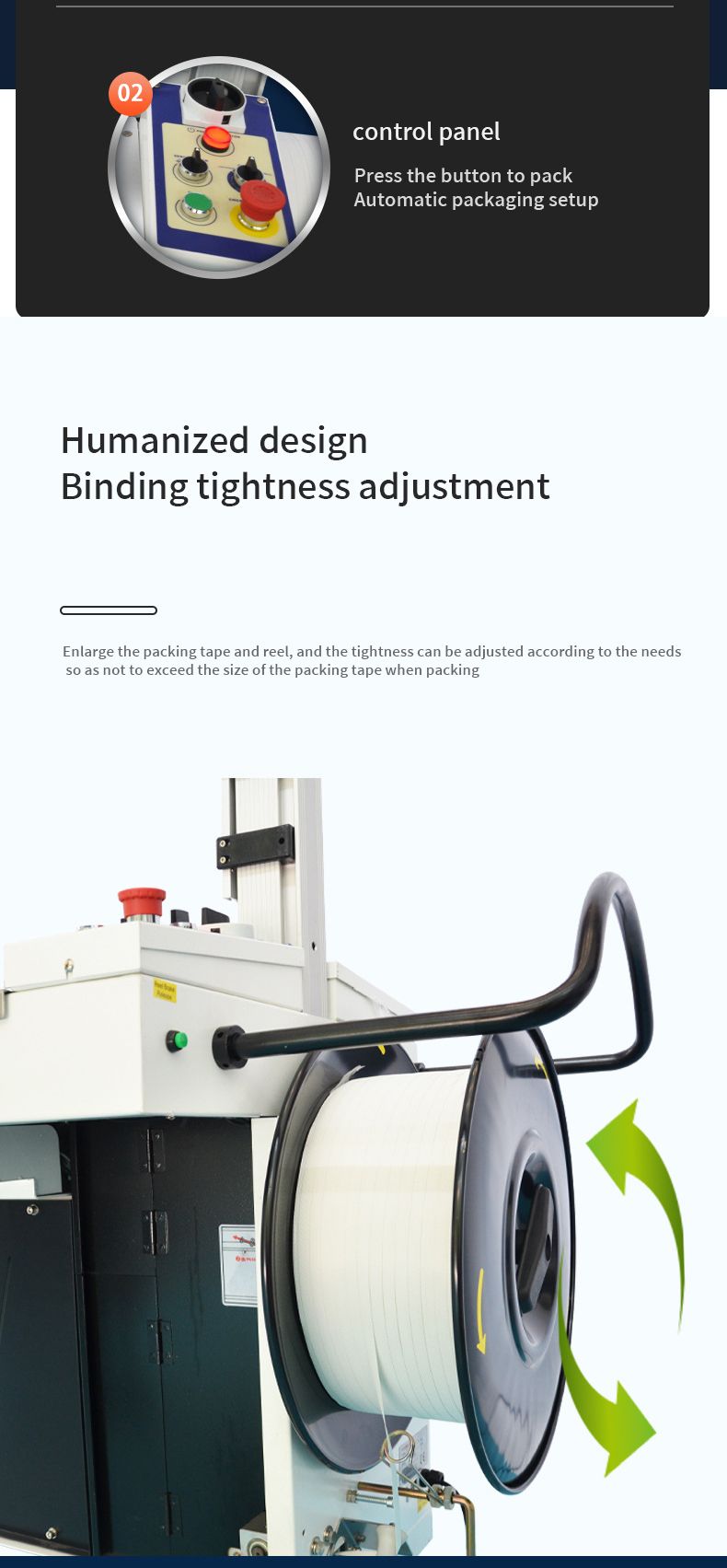

3. Precise control of bundling strength: Through advanced sensors and control systems, the bundling strength can be precisely controlled to ensure that each package is bundled to a consistent degree. It will neither be too loose and cause the package to fall apart during transportation or storage, nor will it cause the package to fall apart during transportation or storage. Over-tightening may damage the contents of the package.

4. Accurate positioning: For items of different sizes and shapes, the intelligent and efficient strapping machine can accurately position and bundle items, ensuring the accuracy and consistency of the bundling position, making the packaging more neat and beautiful.

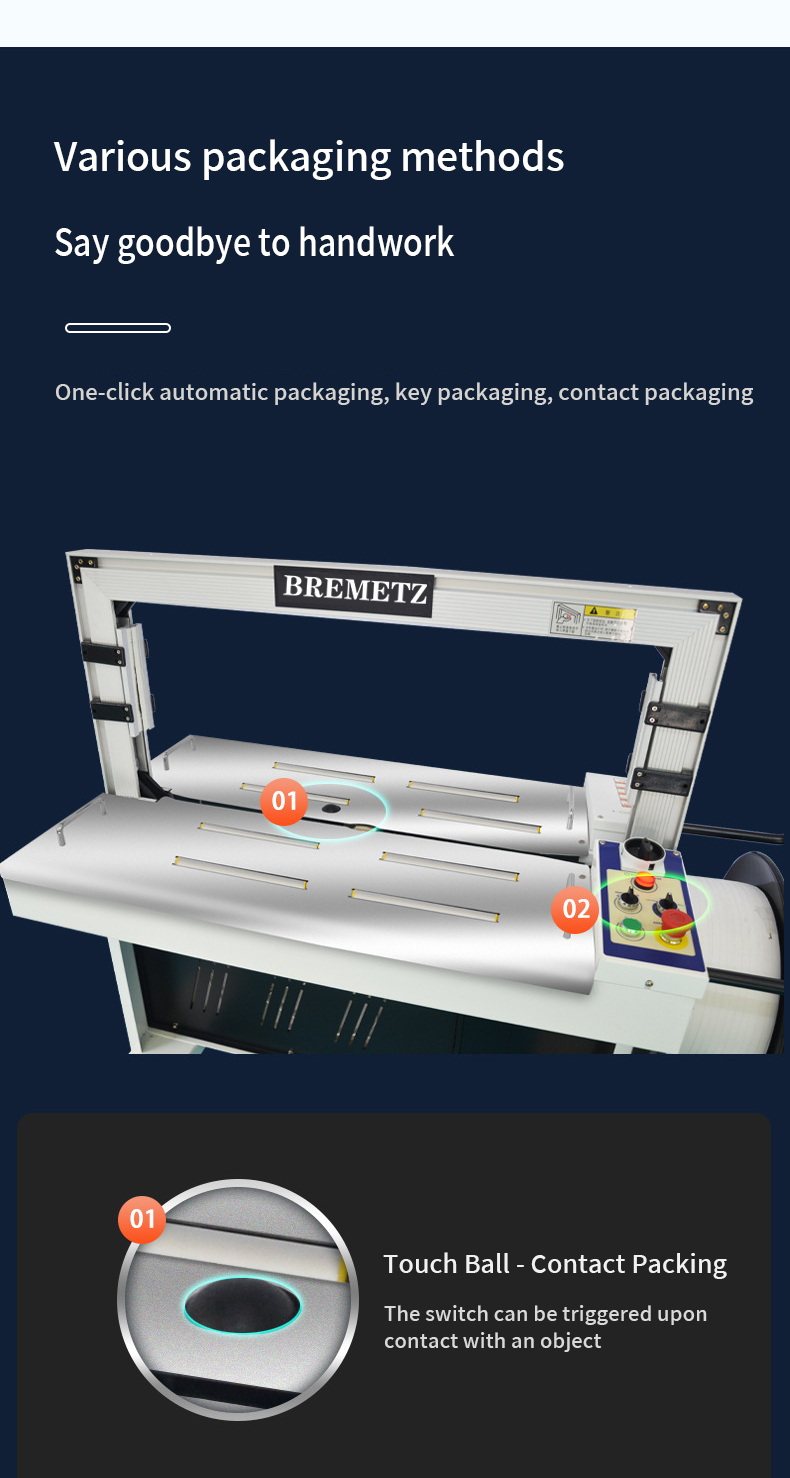

5. Automatic operation: The automated operation process is realized. Just set the relevant parameters, and the equipment can automatically complete a series of actions such as feeding, bundling, and cutting, reducing the tedious process of manual operation, reducing labor intensity and labor costs.

6. Intelligent adjustment: It can automatically adjust the bundling method, strength, speed and other parameters according to different item characteristics and packaging requirements, adapting to a variety of complex packaging scenarios.

7. Suitable for a variety of strapping materials: It can be compatible with a variety of strapping materials of different materials and specifications, such as plastic straps, steel straps, paper straps, etc., to meet the packaging needs of different industries and products. Enterprises can choose appropriate strapping materials according to actual conditions to reduce packaging costs.

Intelligent and efficient strapping machine is a modern packaging equipment that integrates advanced technology, high efficiency, precision and intelligence. It is widely used in logistics, warehousing, manufacturing, commerce and other fields, aiming to provide fast, stable and high-quality strapping and packaging solutions for various items, effectively improve packaging efficiency and quality, and reduce labor costs and packaging errors.

Intelligent and efficient strapping machines mainly complete the strapping process through the coordinated work of mechanical transmission, electronic control and sensor monitoring. First, the motor drives the strapping mechanism to transport the strapping tape from the reel to the strapping position. In this process, the control system accurately controls the strapping length and speed according to the preset parameters and the information fed back by the sensor. When the object is in the appropriate strapping position, the clamping mechanism fixes the object, and then the tensioning mechanism applies appropriate tension to the strapping tape to make the strapping tape fit the object tightly. Then, the cutting device cuts the strapping tape, and for some types of strapping tape, there will be a welding device to firmly connect the ends of the tape.

Sturdy frame: The frame is made of high-strength steel or alloy materials, and is precisely welded and processed to ensure the rigidity and stability of the overall structure. This structural design can withstand various pressures and vibrations during the strapping process, ensuring that the equipment does not deform under long-term, high-intensity working conditions, and maintaining the accuracy and stability of the strapping.

High-quality shell: The shell part uses wear-resistant and corrosion-resistant metal plates or engineering plastics. The shell not only provides protection for the internal mechanical parts, preventing external factors such as dust and moisture from affecting the normal operation of the equipment, but also focuses on safety and aesthetics in design.

The equipment is equipped with various types of sensors, including photoelectric sensors, tension sensors, proximity sensors, etc. Photoelectric sensors are used to locate objects and detect the position of strapping belts; tension sensors monitor the tension of strapping belts in real time and feed back to the control system for adjustment; proximity sensors are used to detect the working status and position relationship of each component inside the equipment. These sensors and the control system together form a real-time monitoring network to ensure that any abnormalities during the operation of the equipment can be discovered and handled in a timely manner.

It supports multiple strapping modes, which can be flexibly selected according to the shape, weight and transportation requirements of the items. For example, the cross strapping mode is suitable for square or rectangular items that need to be fixed in all directions; the tic-tac-toe strapping mode can provide more stable support for heavier or larger items; and the parallel strapping mode is often used for strapping long items.

The equipment has undergone strict quality inspection and optimized design, and can operate continuously and stably for a long time. Key components are made of high-quality wear-resistant materials, and with advanced heat dissipation and lubrication systems, the risk of component wear and overheating is reduced, ensuring uninterrupted operation in large-scale production and packaging operations.

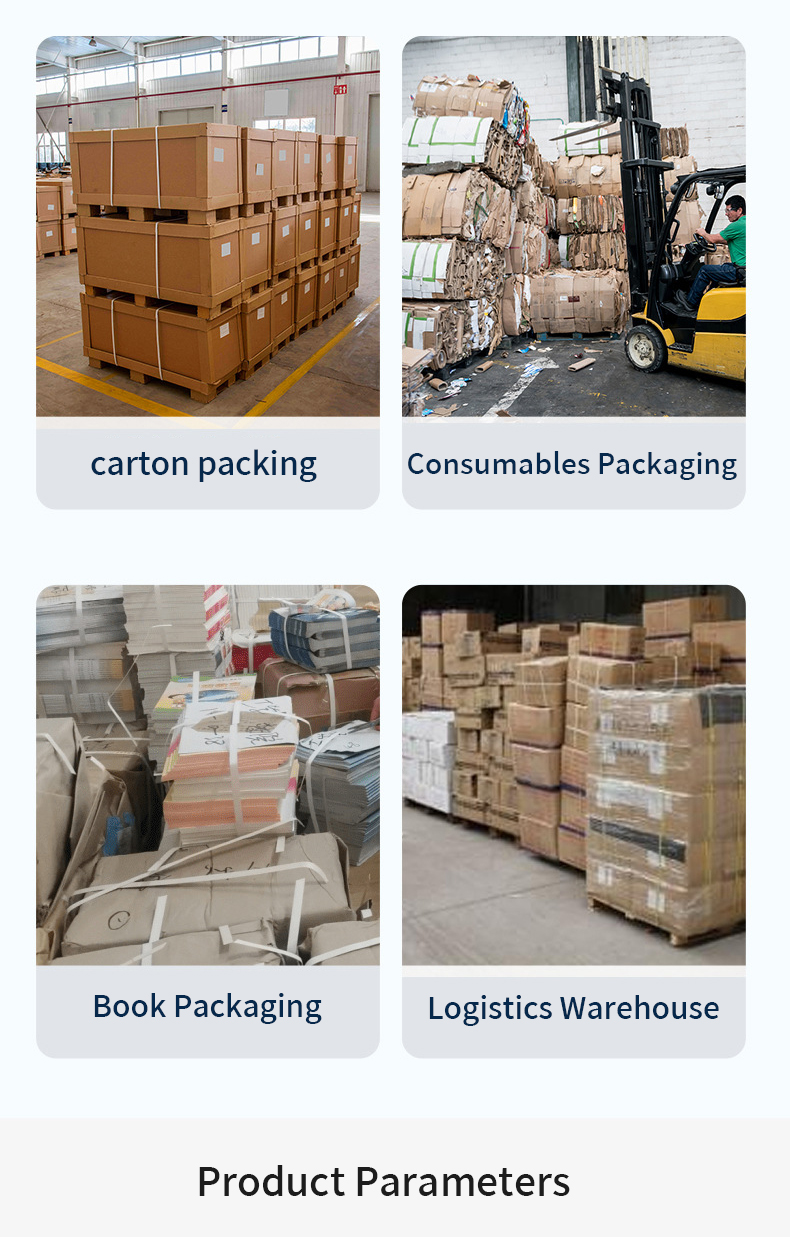

Application areas: Logistics and warehousing industry, in logistics centers and warehouses, intelligent and efficient strapping machines are used to bundle various goods, including e-commerce parcels, pallet goods, etc.

Manufacturing industry, manufacturing enterprises widely use this equipment in product packaging. For enterprises producing mechanical parts, electronic products, furniture and other products, intelligent and efficient strapping machines can select appropriate strapping materials and modes according to the characteristics and packaging requirements of the products.

Building materials industry, building materials such as tiles, wood boards, pipes, etc. are usually large in size and heavy in weight, requiring reliable strapping methods. Intelligent and efficient strapping machines can use steel belts or high-strength plastic belts to bundle these building materials products to ensure their stability during handling and transportation.

In the agricultural field, intelligent and efficient strapping machines also play an important role in the packaging and transportation of agricultural products.

Commercial and retail industries, in the commercial and retail links, intelligent and efficient strapping machines are used to bundle and package goods, such as gift packaging, supermarket promotional goods bundling, etc. Its beautiful and firm bundling effect can enhance the attractiveness of the goods and facilitate customers to carry.

product name:Bundle material packaging machine

Product model:BLMC-101

Countertop Height:750mm

Weight-bearing capacity: 80KG

Product Net Weight:220KG

Product Power: 1000w, 10A

Use bandwidth:9,10, 12, 15mm

Product power supply: 3P,380V,50HZ

Product Size:1435x630x1455mm

Standard frame:W800mmxH600mm

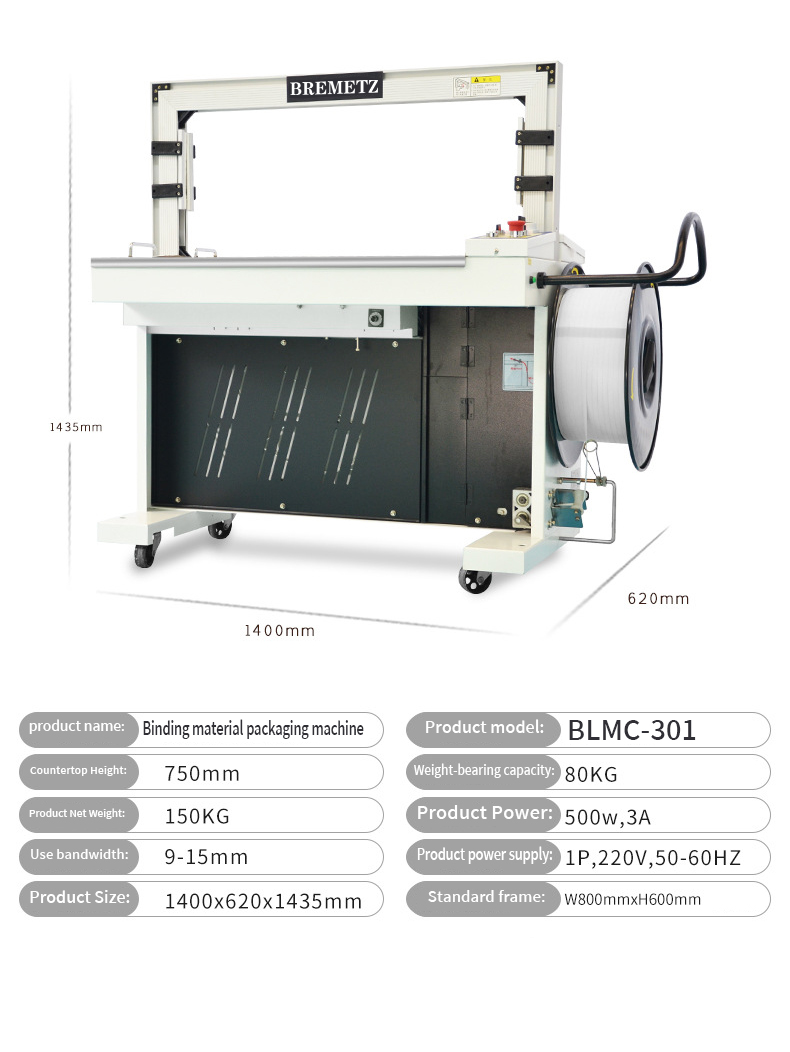

product name:Binding material packaging machine

Product model:BLMC-301

Countertop Height:750mm

Weight-bearing capacity:80KG

Product Net Weight:150KG

Product Power:500w, 3A

Use bandwidth:9-15mm

Product power supply: 1P,220V,50-60HZ

Product Size:1400x620x1435mm

Standard frame:W800mmxH600mm