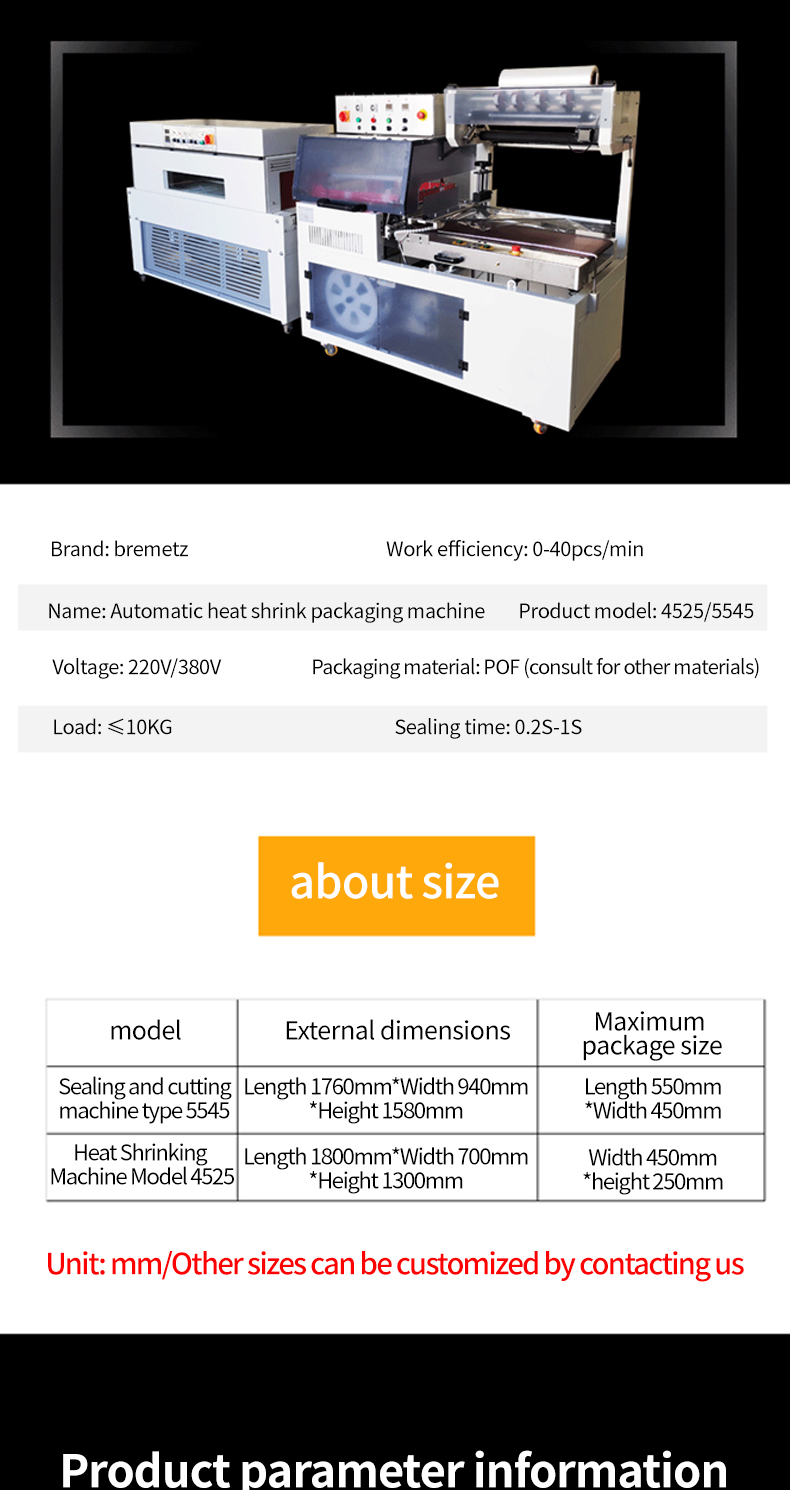

Sealing and shrinking packaging machine

1. Tight fit: Shrink packaging can make the packaging film fit tightly on the surface of the product to form a complete protective cover, effectively preventing the product from being transported.

2. Beautiful appearance: After shrink packaging, the product has a neat, smooth and shiny appearance, which can enhance the overall beauty and grade of the product.

3. Strong fixation: It can fix multiple products or parts of products together to prevent them from moving or scattering in the package.

4. Product diversity: It can package products of various shapes, sizes and types, whether they are regular or irregular.

5. Fast packaging speed: With a high packaging speed, it can complete the packaging task of a large number of products in a short time, improve production efficiency, and meet the large-scale production needs of enterprises.

6. High energy utilization efficiency: In the shrink packaging process, advanced heating technology and control system are used to accurately control the heating temperature and time.

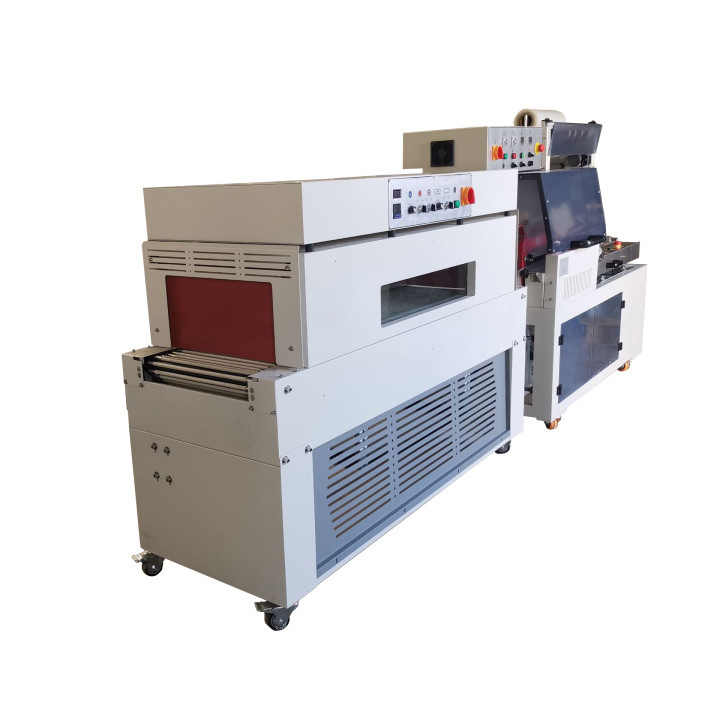

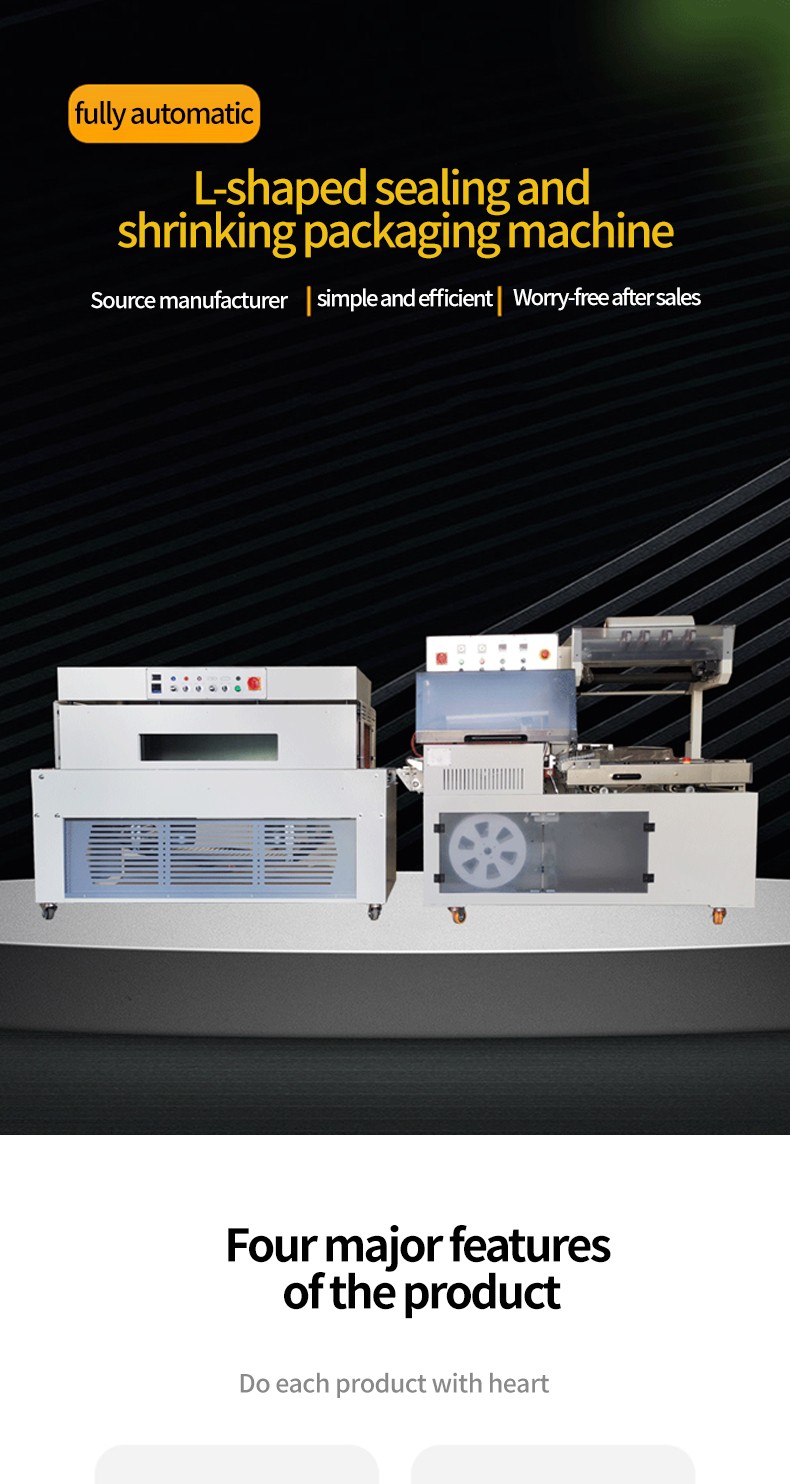

The sealing, cutting and shrinking packaging machine is an advanced packaging equipment that integrates the two packaging functions of sealing, cutting and shrinking. It is widely used in many industries such as food, daily necessities, medicine, hardware, electronics, etc. It provides high-quality, beautiful and well-protected packaging for products by sealing, cutting and shrinking the packaging materials, effectively improving the added value and market competitiveness of the products.

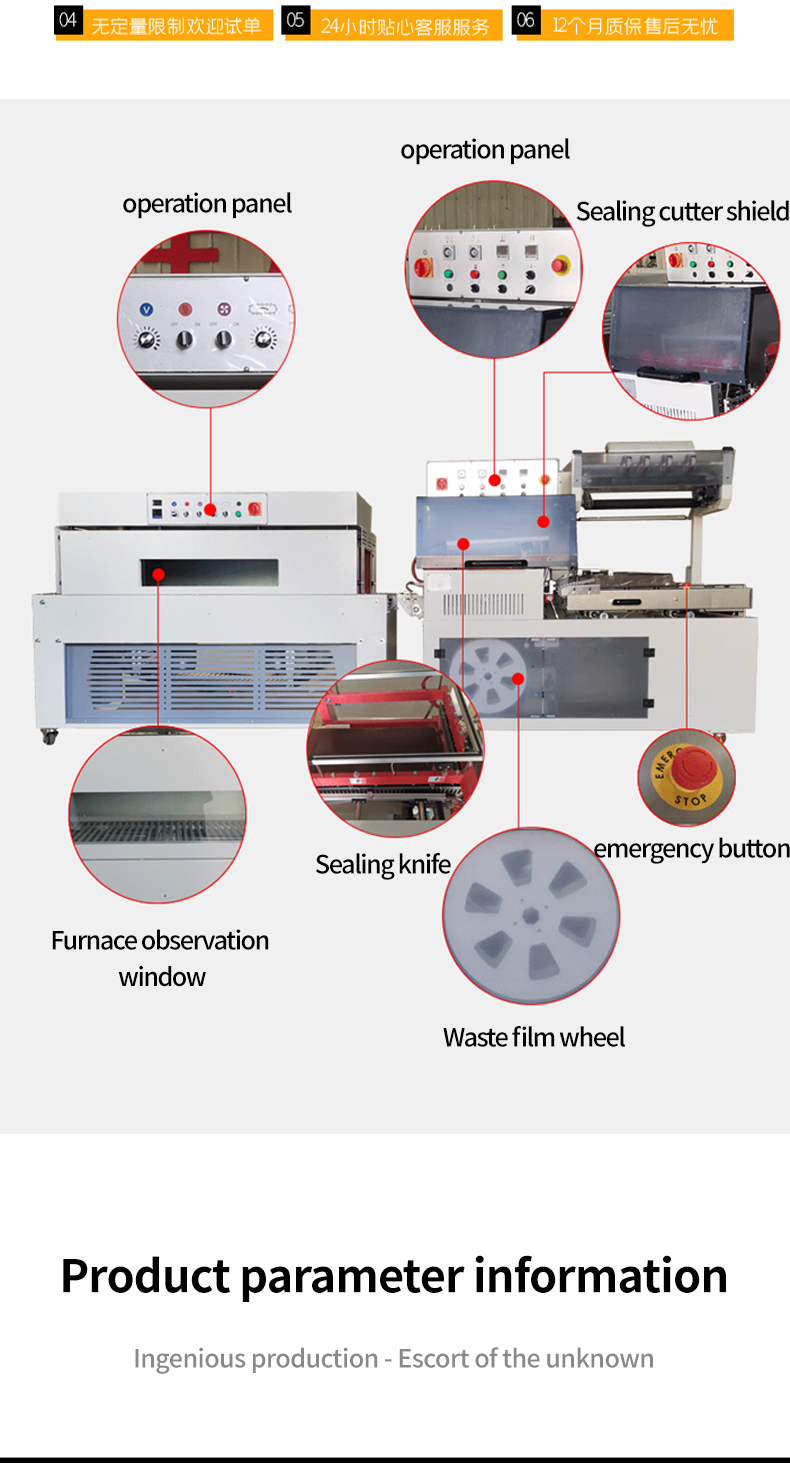

Firm sealing and cutting: By precisely controlling the sealing and cutting temperature and pressure, it is possible to ensure that the sealing of the package is firmly sealed, effectively preventing product leakage and external contamination, and ensuring the stability of the product during transportation and storage.

Tight shrinkage: The shrinkage process makes the packaging film fit the product tightly, which not only provides good protection, but also makes the product appearance more beautiful and neat, improves the product display effect, and helps to attract consumers.

Fast sealing, cutting and shrinking: The equipment has a high sealing, cutting and shrinking speed, and can complete the packaging of a large number of products in a short time, meeting the needs of large-scale production, effectively improving production efficiency and reducing unit production costs.

Brand: bremetz

Work efficiency: 0-40pcs/min

Name: Automatic heat shrink packaging machine

Product model: 4525/5545

Voltage: 220V/380V

Packaging material: POF (consult for other materials)

Load: <10KG

Sealing time: 0.2S-1S

model:Sealing and cutting machine type 5545,Heat Shrinking Machine Model 4525

External dimensions:Length 1760mm*Width 940mm *Height 1580mm,Length 1800mm*Width 700mm *Height 1300mm

Maximum package size:Length 550mm *Width 450mm,Width 450mm *height 250mm

Compatible with multiple products: It can package products of various shapes, sizes and types, from food, daily necessities to hardware, electronics and other industries, without the need to frequently change equipment for different products.

Applicable to multiple materials: It has good adaptability to packaging materials of different materials and thicknesses (such as plastic films, composite films, etc.), and can flexibly select suitable packaging materials according to product characteristics and packaging requirements.

Simple operation: The touch screen operation panel and intuitive parameter setting method enable operators to easily master the operation of the equipment, reducing the skill requirements for operators, reducing training time and costs.

Easy to maintain: The equipment structure is designed for easy maintenance, key components are easy to disassemble and replace, and equipped with fault diagnosis and alarm functions, which facilitates maintenance personnel to find and solve problems in time and improve equipment utilization.

Safety protection: The equipment is equipped with complete safety protection devices, such as emergency stop button, protective door sensor, overload protection, etc., to ensure the safety of operators and the normal operation of equipment.

Application areas:

Food industry: used to package various foods. Shrink packaging can extend the shelf life of food and keep it fresh and hygienic.

Daily necessities industry: widely used in the packaging of daily necessities. Through sealing and shrink packaging, the packaging quality and aesthetics of the product are improved.

Pharmaceutical industry: strict sealing and shrink packaging process ensures the sealing and hygiene of the medicine, and meets the requirements of the pharmaceutical production quality management specification.

Hardware and electronics industry: suitable for packaging hardware accessories, etc. Provide good protection for these products to prevent collision, scratches and static electricity during transportation.

Most regular manufacturers will provide on-site installation services to ensure that the equipment can be properly installed and placed at the location specified by the customer, ensuring the stability and safety of the equipment.

Provide detailed equipment operation training for customers' operators to familiarize them with the equipment's control panel, operation buttons, various functions and correct operation procedures.

When a device fails, the customer reports the problem to the after-sales service department. The manufacturer will respond within the specified time. Generally, the manufacturer will contact the customer within 24 hours to understand the fault situation and arrange for maintenance personnel to come to the customer's home for repair or provide remote technical support based on the severity and urgency of the fault.