Fully automatic liquid filling machine, technology leads the development

In recent years, with the growing demand for liquid product packaging in various industries, the fully automatic liquid filling machine industry has shown a booming development trend and has become a key force in promoting the efficient and precise production of liquid products.

According to relevant reports, the market demand for fully automatic liquid filling machines in my country has continued to rise in recent years, and the overall scale of the industry has continued to expand. The rapid development of many industries such as food, beverages, medicine, and daily chemicals has put forward higher requirements for the filling efficiency and quality of liquid products, which has effectively promoted the prosperity of the fully automatic liquid filling machine market.

Precision filling technology upgrade: Modern fully automatic liquid filling machines use advanced metering systems and control technologies, such as high-precision flow meters, weighing sensors, etc., which can achieve precise control of liquid filling volume, and the error can be controlled within a very small range, ensuring that the filling volume of each bottle or barrel of product meets strict standards, effectively improving product quality and consistency.

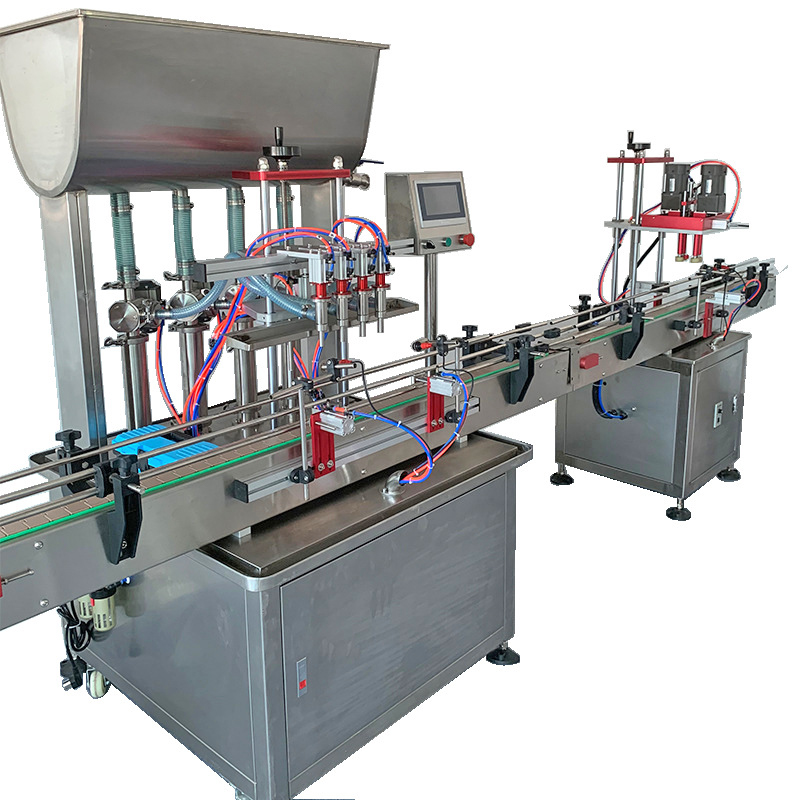

Intelligent automation level improvement: With the help of intelligent control systems and automation technology, fully automatic liquid filling machines can seamlessly connect with upstream and downstream production equipment to achieve automated collaborative operations of the entire production line.

Multifunctional integrated design: In order to meet the needs of different industries and products, fully automatic liquid filling machines continue to develop in the direction of multifunctional integration. In addition to the basic filling function, some equipment also integrates multiple functions such as sealing, labeling, and coding, realizing multiple uses of one bottle, reducing the equipment footprint, and reducing the company's equipment procurement and production costs.