Online Pallet Wrapping Machine

1. Improve production efficiency: It can seamlessly connect with the production line to realize a series of operations such as automatic feeding, wrapping, and discharging of pallet goods.

2. Uniform packaging effect: Through precise control systems and mechanical structures, ensure that the wrapping force of the stretch film on the pallet is uniform.

3. Customizable packaging: The packaging parameters can be flexibly adjusted according to different product characteristics and packaging requirements.

4. Multiple pallet sizes and cargo types: It can adapt to pallets of different sizes and cargo packaging of various shapes, weights and materials, with strong versatility and flexibility.

5. Different packaging materials can be used: Stretch film is generally used as the main packaging material, but stretch film of different specifications and materials can also be selected according to specific needs.

6. High space utilization: The online pallet wrapping packaging machine has a relatively compact structure and a small footprint, which can effectively save space in the production workshop or warehouse and improve space utilization.

Online Pallet Wrapping Machine is a kind of equipment used for pallet cargo packaging. It can wrap the stretch film tightly around the pallet and cargo to fix, protect and prevent dust.Stretch film is mainly used as packaging material, and some machines can also use other similar plastic films.

The pallet cargo enters the turntable through the conveyor line. After the photoelectric switch senses the cargo, the pallet conveyor line stops conveying and the turntable starts. The turntable drives the cargo to rotate, and at the same time the film system releases the stretch film and wraps the cargo according to the set parameters. After wrapping is completed, the equipment automatically stops, cuts the film, fixes the tail film, and finally sends the packaged cargo out of the turntable.

High packaging quality: Through precise control systems and mechanical structures, the wrapping force of the stretch film on the pallet is ensured to be uniform, and the packaging is tight, neat and beautiful, effectively preventing the displacement and scattering of goods during transportation and storage, and providing good protection for the products.

Product name: On-line winding packagingmachine

Packing size: 1200*1200MM

Packing length: 2000MM (can be extended)

Countertop weighing: 2000KG (can be used as a heavier type)

Formwork structure: Pre-stretched structure can effectively stretch the stretch film by 250%

Turntable speed: 0-12 rpm

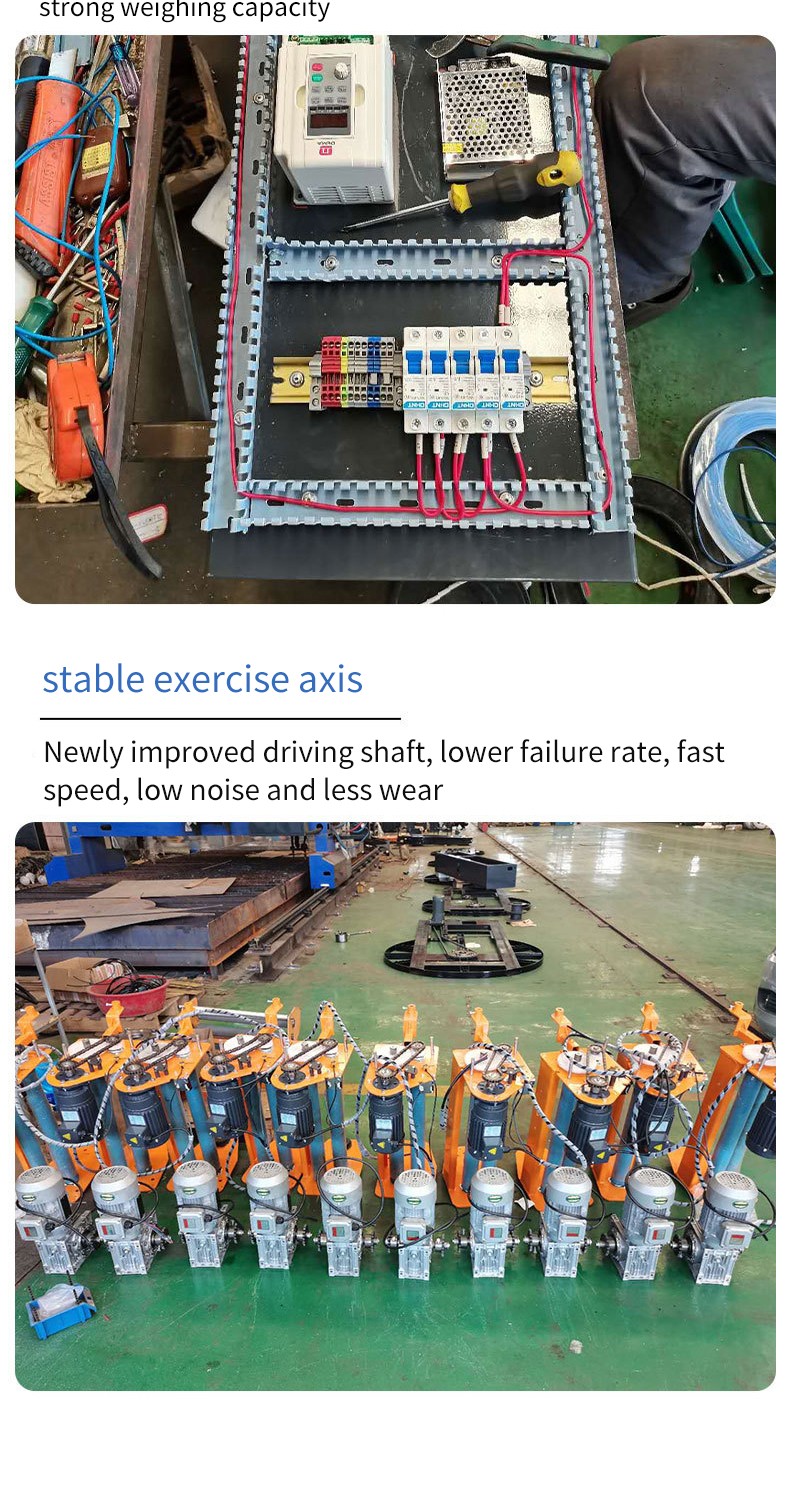

Turntable transmission mode: chain/roller/plate chain

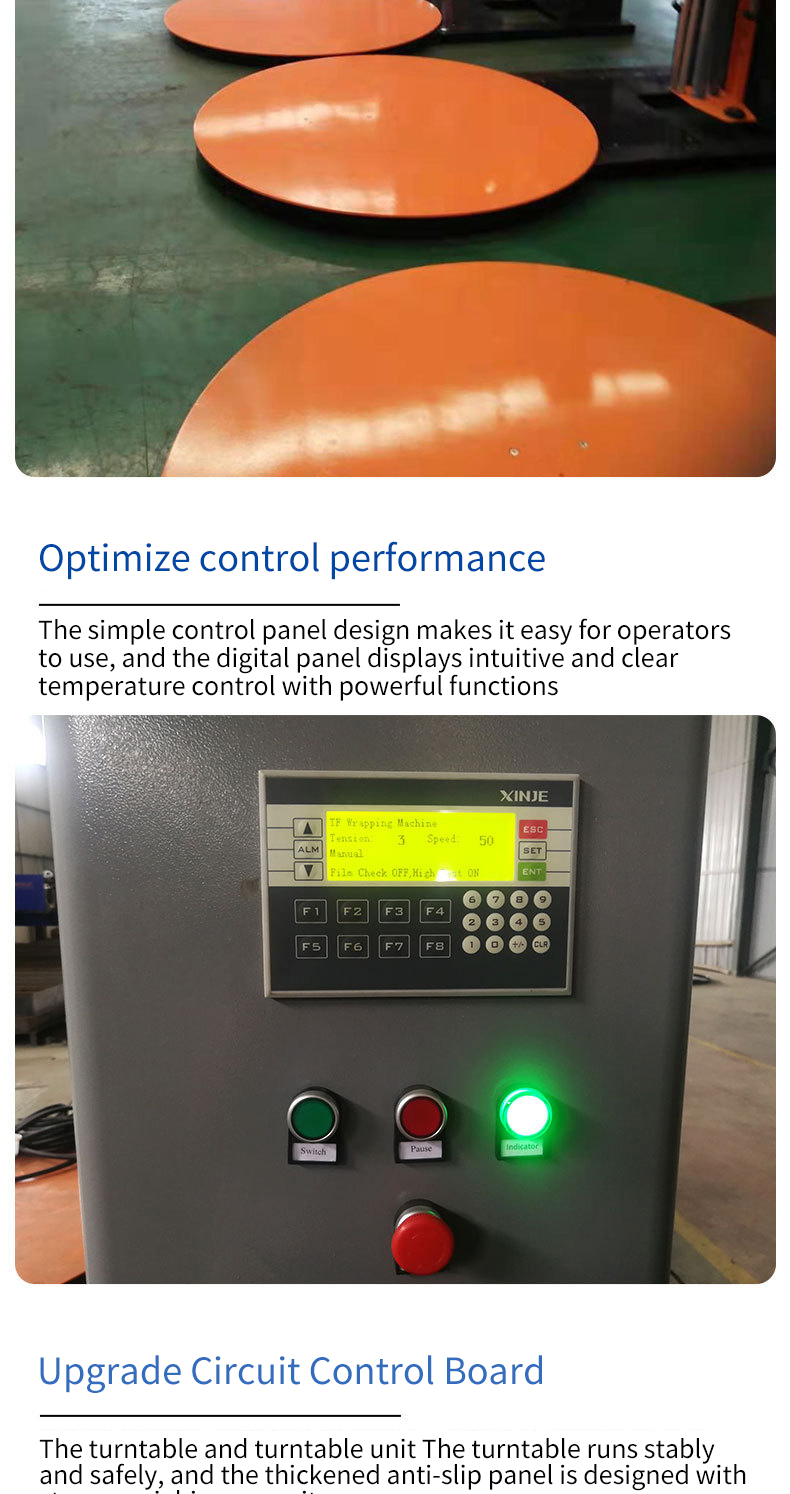

Easy to operate: Equipped with a touch screen or other intuitive operating interface, operators can quickly adjust packaging parameters. At the same time, built-in fault diagnosis and alarm functions make it easy for maintenance personnel to quickly locate and solve problems, reducing equipment downtime.

The equipment has stable and reliable performance: it adopts high-quality mechanical structure and components, and is equipped with advanced control systems, which can operate stably for a long time, reduce equipment failures and maintenance times, and have a long service life.

Wide range of applications: It can adapt to pallets of different sizes and cargo packaging of various shapes, weights and materials. It can also use stretch films of different specifications and materials to meet the needs of different industries and customers.

High safety performance: Equipped with complete safety protection devices, such as guardrails, light curtain sensors, emergency stop buttons, etc. At the same time, in the design and manufacturing process, relevant safety standards and specifications are strictly followed to ensure the safety of operators.

Energy saving and environmental protection: Energy-saving motors, inverters and other equipment are used to automatically adjust the power according to the actual workload and reduce energy consumption. In addition, precise film stretching and winding control can reduce film waste, reduce packaging costs, and meet environmental protection requirements.

Operation training: The manufacturer will provide free operation training for the customer's operators to familiarize them with the equipment's operation methods, parameter settings, daily maintenance and other knowledge.

Maintenance training: Teach the customer's maintenance personnel how to perform daily maintenance, troubleshooting and simple repairs on the equipment to extend the service life of the equipment and reduce the failure rate of the equipment.

Software upgrade service: With the continuous development of technology and changes in customer needs, manufacturers will upgrade the control system software of the equipment to improve the performance, function and stability of the equipment, and provide customers with free or paid software upgrade services.