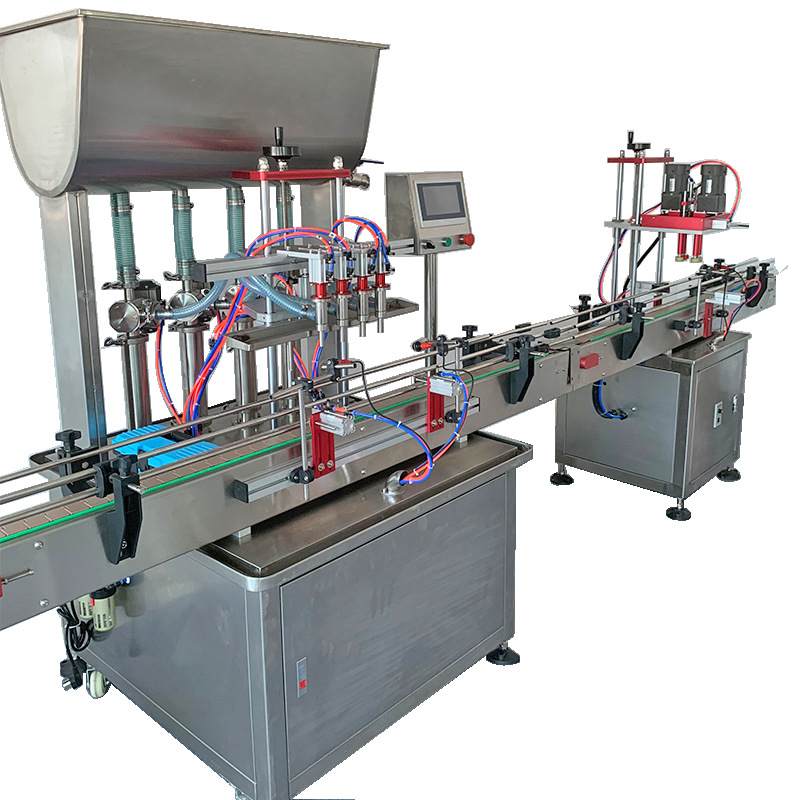

Fully automatic liquid filling machine

1. High-speed filling: The machine has an advanced filling system that can achieve fast and continuous filling operations.

2. Continuous and stable operation: The use of high-quality mechanical structure and automatic control system ensures the stability of the equipment during long-term operation.

3. High-precision metering device: Equipped with an advanced metering system, it can accurately control the filling volume of the liquid with a very small error range, usually reaching an accuracy of ±0.5% or even higher.

4. Multi-specification adaptability: It can adapt to packaging containers of different capacity specifications by simply adjusting parameters or replacing some parts.

5. Fully automated process: A series of operations from bottle delivery, positioning, filling to the final capping can be completed automatically without manual intervention.

6. Material and structural design: The main body of the equipment is usually made of high-quality stainless steel, which has good corrosion resistance and easy cleaning.

Fully automatic liquid filling machine is a highly automated liquid filling equipment, widely used in many industries such as food, beverage, medicine, daily chemicals, etc. It can accurately and efficiently fill various liquids into different types of packaging containers, and realizes the automation of a series of operations from container transportation, liquid filling to capping (if necessary), which greatly improves production efficiency and product quality, and reduces the errors and pollution that may be caused by manual operation.

Product Name: Filling and capping machine

Filling speed:20-25 bottles/minute

Product material:304 stainless steel/aluminum plate (Filling materials) liquid, semi-fluid, paste.

Product features:Automatic feeding, automatic filling, (automatic capping), automatic capping.

Product Features:Quantitative dispensing, driven by servo motor, precise filling, automatic capping, saving labor.

Product price: Different filling ranges, different output requirements, different prices, please consult customer service for details.

Product customization:Products can be customized according to your requirements.

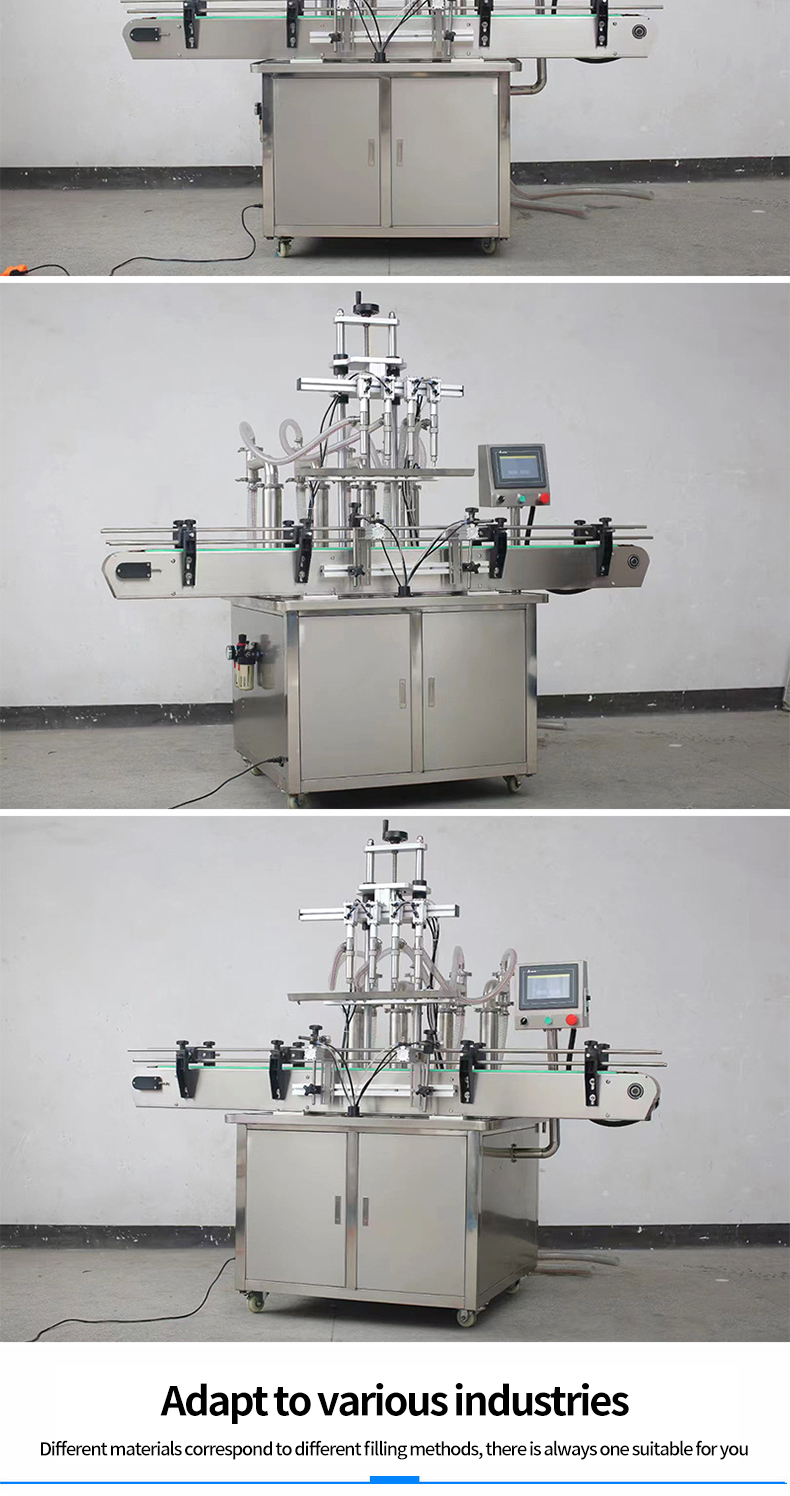

Versatility and flexibility: It can adapt to a variety of liquid types and packaging containers of different specifications. It can be used for filling different products through simple adjustments, which improves the use value of the equipment and the company's return on investment.

Efficient and stable: It has high-speed and continuous filling capabilities and can remain stable during long-term operation, reducing downtime and production delays, and improving production efficiency and economic benefits.

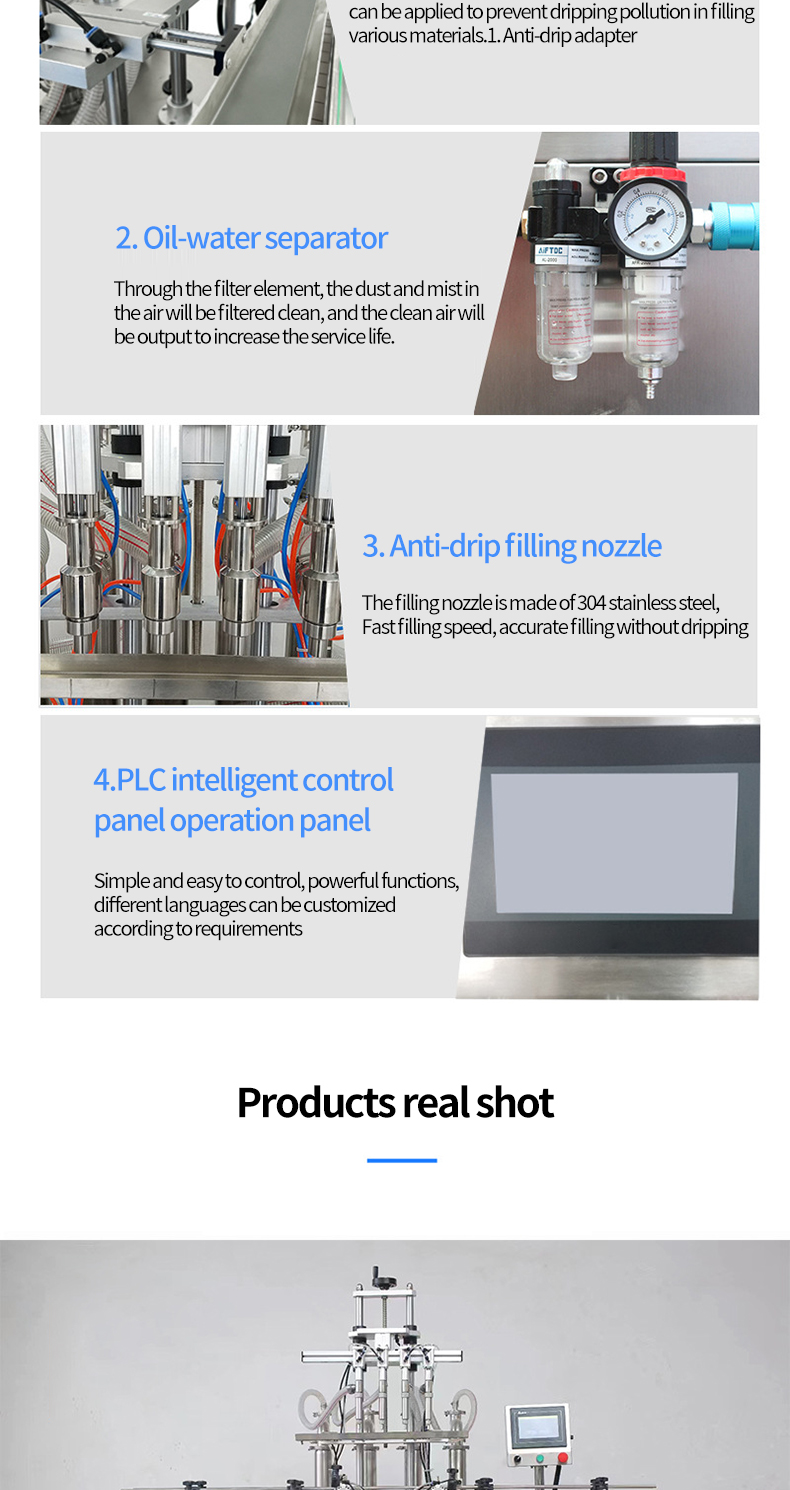

Anti-drip adapter,The utility model has the advantages of simple and reasonable structure, accurate leaking action, andcan be applied to prevent dripping pollution in filling various materials.

Oil-water separator,Through the filter element, the dust and mist in the air will be filtered clean, and the clean air will be output to increase the service life.

Anti-drip filling nozzle,The filling nozzle is made of 304 stainless steel, Fast filling speed, accurate filling without dripping.

PLC intelligent control panel operation panel,Simple and easy to control, powerful functions, different languages can be customized according to requirements.

Hygiene and safety: It adopts materials and structural design that meet hygiene standards, is easy to clean and disinfect, can effectively prevent liquid contamination, and meet the production needs of industries such as food and medicine that have high requirements for hygiene conditions.

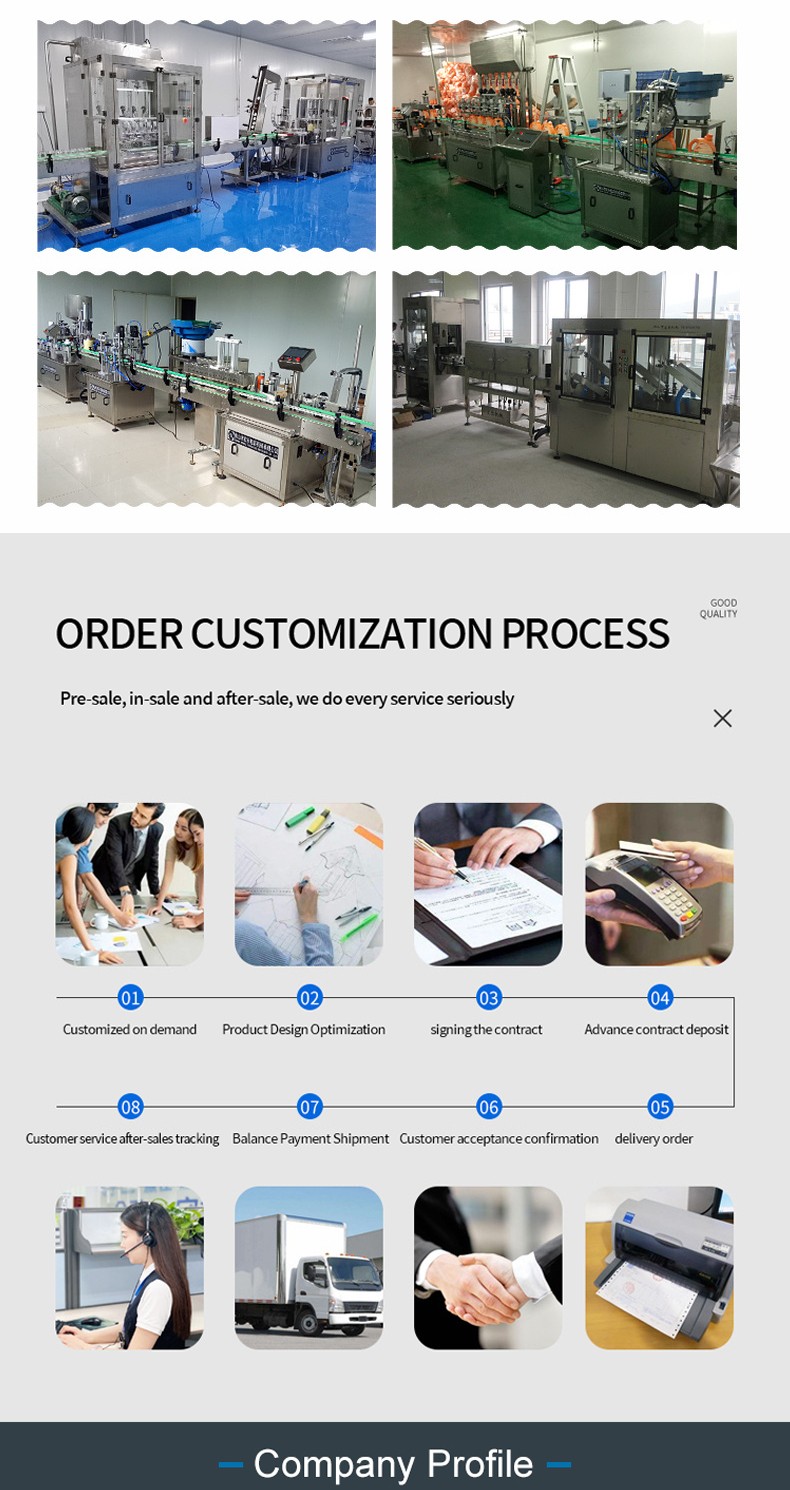

An experienced team of technical engineers is responsible for the installation of the equipment. They will accurately locate and fix the equipment according to the customer's production site layout and equipment requirements to ensure that the equipment is installed firmly and stably. During the installation process, the standard operating procedures in the equipment installation manual are strictly followed to ensure that the connections of each component are tight and accurate, laying the foundation for the normal operation of the equipment.

Operation training: Provide customers with professional operation training courses. The training content covers the basic operation principles of the equipment, detailed function introduction of the operation panel, setting methods of various parameters, and daily operation processes such as equipment start-up, stop, emergency handling, etc.

Maintenance training: In addition to operation training, we also provide customers with equipment maintenance training. The training content includes daily maintenance knowledge of equipment, troubleshooting and treatment methods of common faults, replacement steps of wearing parts and key points of regular equipment maintenance.

Quick response maintenance: Establish a complete after-sales service network and quick response mechanism. When a customer's equipment fails, the customer can contact the after-sales service center in a timely manner through various means such as phone, email, online customer service, etc. The after-sales service team will respond as soon as possible after receiving the repair information, and quickly arrange technicians to rush to the site for repair according to the severity of the fault and the specific needs of the customer.

We pay attention to the development of industry technology and potential needs of customers, and provide customers with equipment upgrade services in a timely manner. The upgrade content may include software updates of the control system, improvements in filling technology, improvements in metering accuracy, and improvements in the degree of equipment automation. Through equipment upgrades, customers' equipment can always maintain advanced performance and high production efficiency, better meet the needs of market changes and corporate development, and enhance customers' market competitiveness.