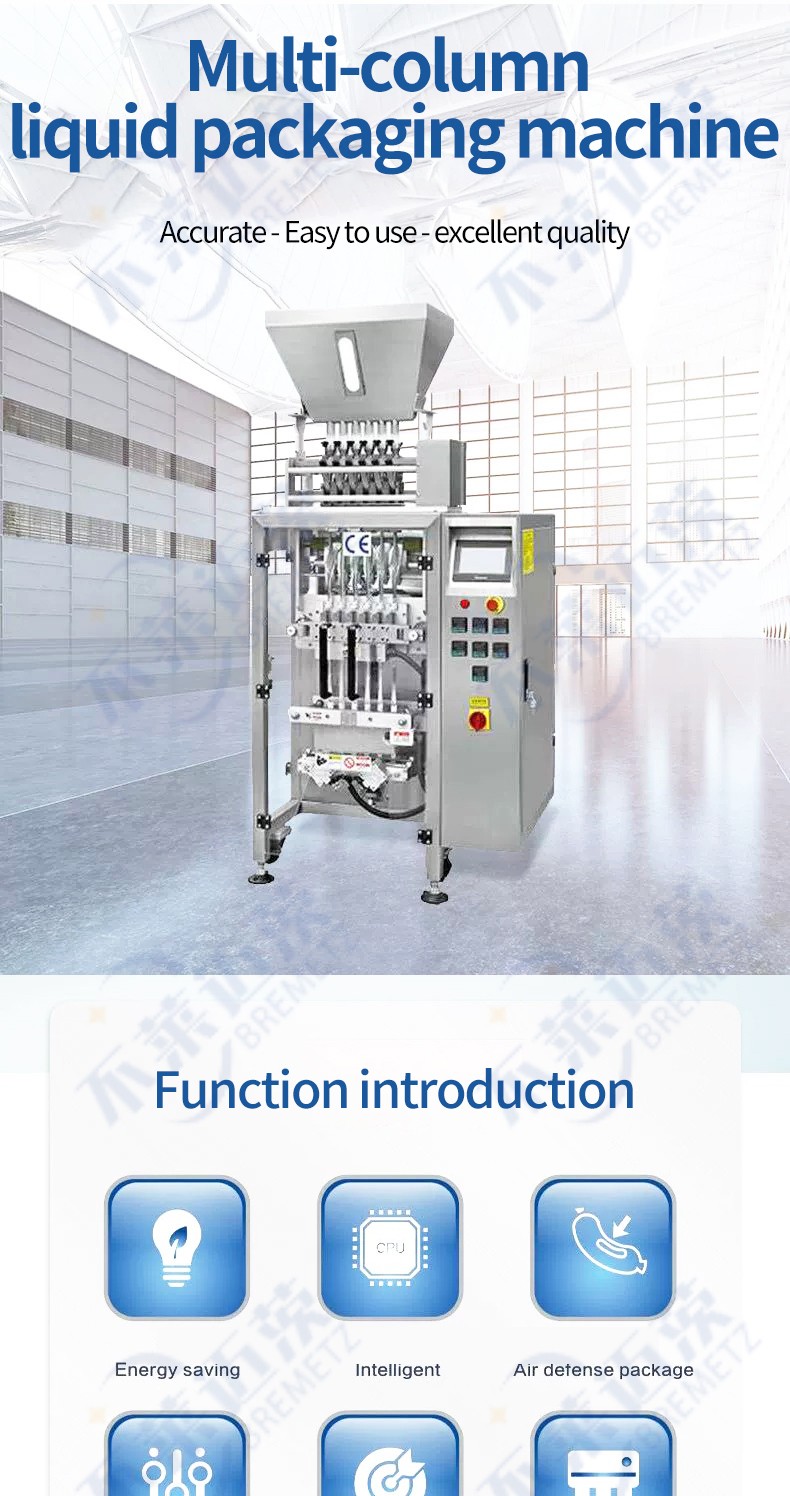

Multi-lane liquid packaging machine

1. Multi-channel parallel filling: equipped with multiple filling channels, multiple packaging containers can be filled at the same time.

2. High-speed and stable operation: using advanced transmission system and control system, the operation speed is fast and stable, reducing the downtime and failure probability of the equipment.

3. Accurate control of filling volume: using high-precision metering devices, such as volumetric metering pumps, weighing sensors, etc., can accurately control the liquid filling volume in each packaging container.

4. Multiple metering methods are optional: according to different liquid characteristics and packaging requirements, different metering methods can be selected, such as volumetric metering, weight metering, etc.

5. Suitable for a variety of liquids: It can handle liquid materials of various viscosities, densities and fluidities, and achieve stable filling of different materials by adjusting the structure and parameters of the filling head.

6. Compatible with different packaging containers: It can match packaging containers of various shapes and specifications. Just replace the corresponding filling head and positioning device to achieve filling operations for different containers.

Multi-lane liquid packaging machine is an advanced liquid packaging equipment, which mainly uses piston pumps, metering pumps and other metering devices to accurately control the filling volume of liquid, and then uses the sealing device to seal the packaging container to complete the liquid packaging operation.

High efficiency: With multiple filling channels, it can fill and package multiple packages of liquid at the same time, with extremely high production efficiency, which can greatly shorten production time and improve the company's production capacity.

High precision: Equipped with high-precision metering devices and advanced control systems, it can accurately control the filling volume of liquid, ensure that the volume or weight of liquid in each package is highly consistent, and effectively ensure product quality.

Strong adaptability: It can be applied to various types of liquids, including low-viscosity water and beverages, medium-viscosity emulsions and sauces, and high-viscosity pastes, etc. At the same time, it is also compatible with packaging containers of different shapes and specifications, such as plastic bottles, glass bottles, and soft packaging bags.

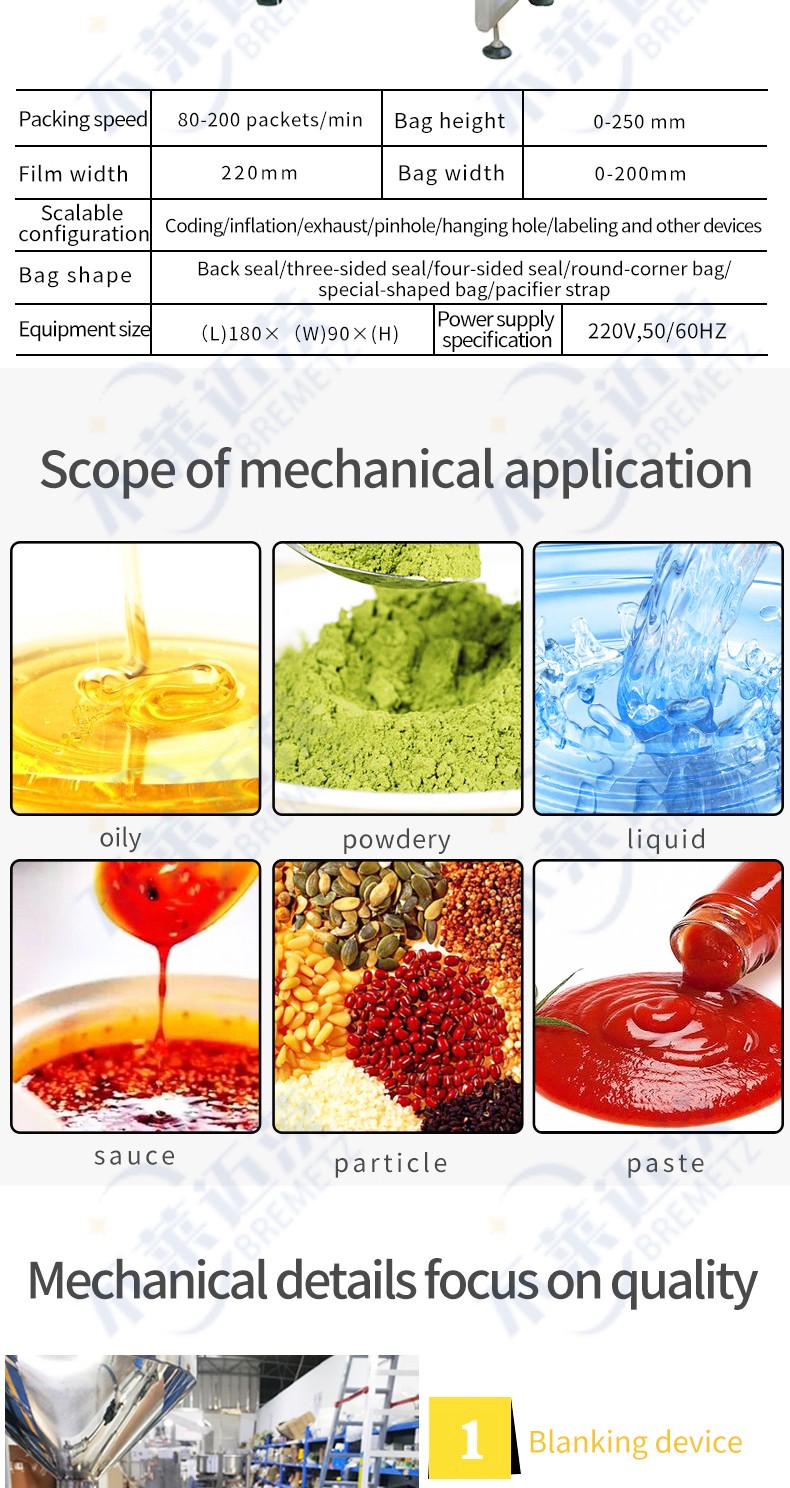

Packing speed:80-200 packets/min

Bag height:0-250 mm

Film width:220mm

Bag width:0-200mm

Scalable configuration:Coding/inflation/exhaust/pinhole/hanging hole/labeling and other devices

Bag shape:Back seal/three-sided seal/four-sided seal/round-corner bag/ special-shaped bag/pacifier strap

Equipment size:(L)180×(W)90×(H)

Power supply specification:220V,50/60HZ

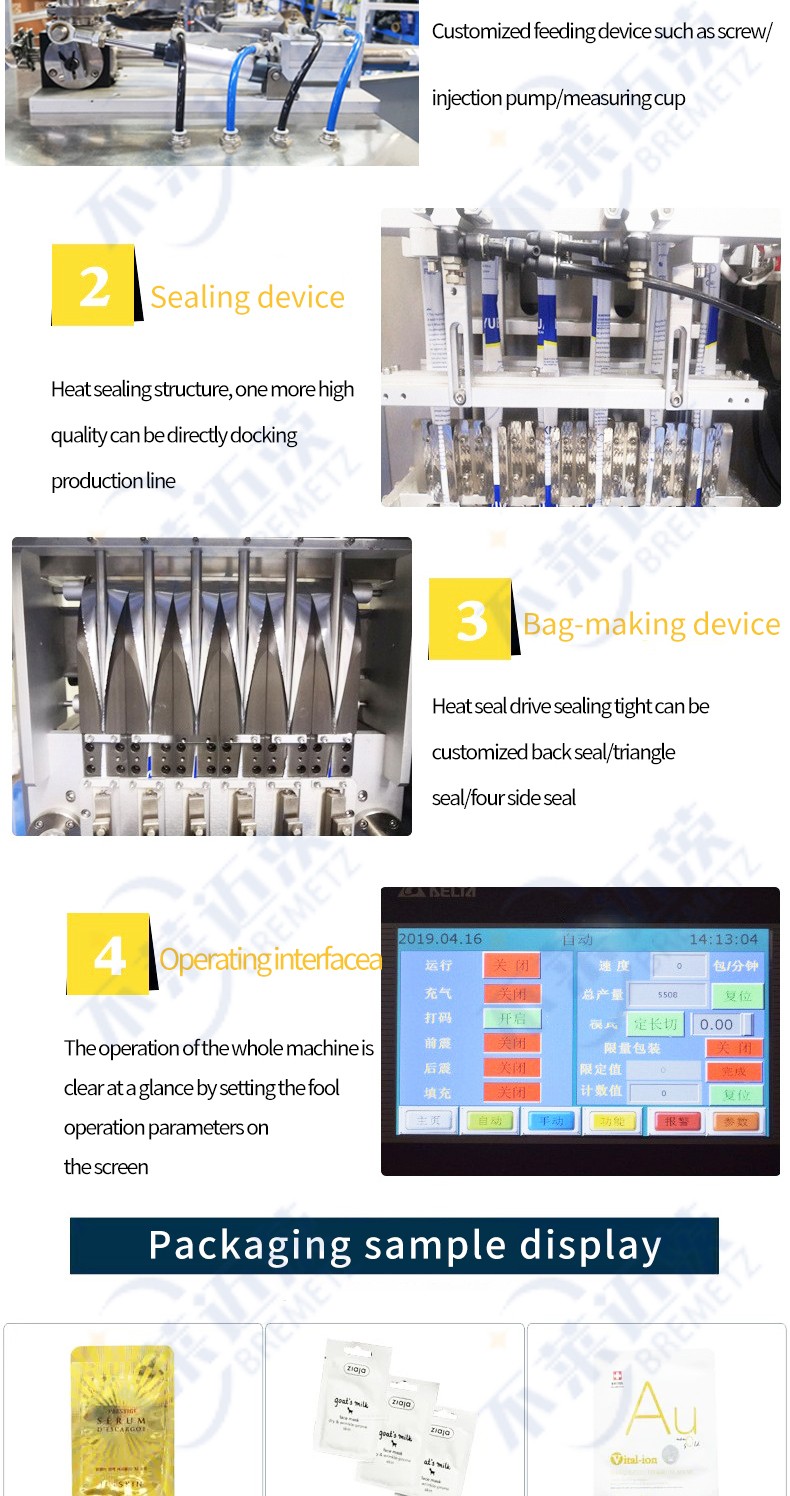

High degree of automation: The PLC control system and human-machine interface are used to realize the automatic operation and intelligent management of the equipment. The operator only needs to set the relevant parameters on the human-machine interface, and the equipment can automatically complete a series of packaging processes such as material transportation, filling, sealing, labeling, counting, etc., which greatly reduces manual intervention.

High reliability: The overall structure is reasonably designed, using high-quality materials and components, with good stability and durability, able to operate stably for a long time, reducing the failure rate and maintenance cost of the equipment.

Application areas: In the food and beverage industry, it can be used to package various liquid products such as milk, juice, soy sauce, vinegar, edible oil, etc.; in the cosmetics industry, it is suitable for packaging lotions, toners, essences, perfumes, etc.; in the pharmaceutical industry, it can be used to fill oral liquids, injections, eye drops and other pharmaceutical liquids; in addition, in other industries such as chemicals, it can also be used to package various liquid chemicals, glue, etc.