Express packaging machine

1. It can complete the packaging of a large number of express parcels in a short time, greatly improving the packaging efficiency and meeting the express industry's demand for rapid processing of a large number of parcels.

2. It can run uninterruptedly for a long time, reducing production delays caused by equipment downtime and ensuring the continuity of the express packaging process.

3. With the help of advanced sensor technology and precise measurement system, it can accurately measure the size of express parcels, so as to select the appropriate packaging materials and packaging methods for the parcels.

4. The automated operation process reduces the dependence on manual packaging, reduces the manpower investment of express companies, and saves a lot of labor costs.

5. Through precise measurement and intelligent packaging design, it can reasonably use packaging materials, avoid excessive waste of materials, and reduce packaging costs.

Express packaging machines are indispensable key equipment in the modern express delivery industry. They integrate advanced technologies from multiple fields such as mechanical engineering, automatic control, and electronic information technology, aiming to achieve automation, efficiency, and precision in the express package packaging process.

The use of high-precision measuring equipment and advanced control systems can accurately measure the size, weight and other parameters of express parcels, and automatically adjust the working state of the packaging machine and the amount of packaging materials according to these parameters to ensure that each parcel can be properly packaged.

It is compatible with a variety of common express packaging materials, such as cartons, plastic films, woven bags, etc., and can perform corresponding processing and operations according to the characteristics of different packaging materials.

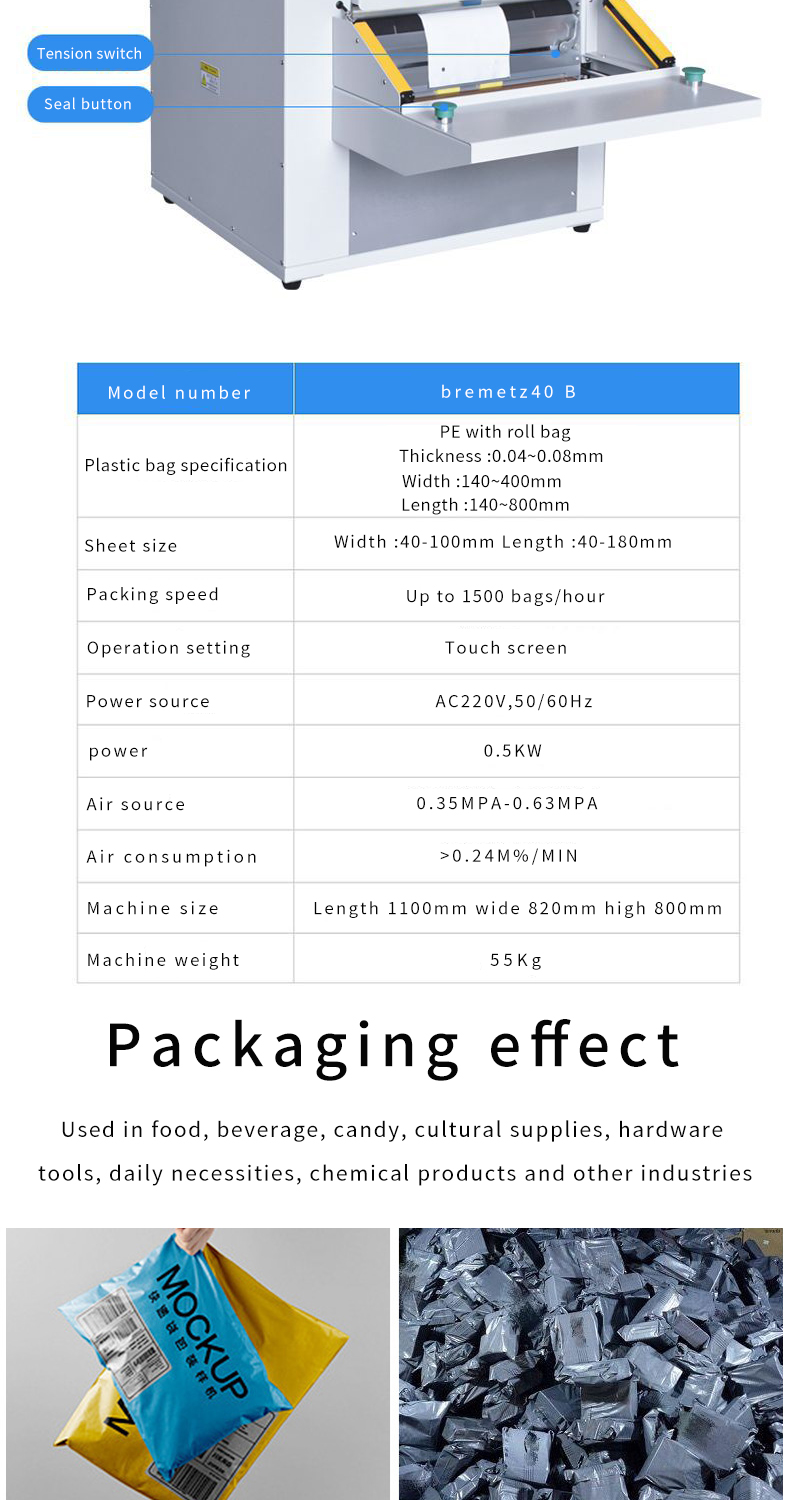

Model number:bremetz40B

Plastic bag specification:PE with roll bag,Thickness:0.04~0.08mm,Width:140~400mm,Length: 140~800mm

Sheet size:Width:40-100mm Length: 40-180mm

Packing speed:Up to 1500 bags/hour

Operation setting:Touch screen

Power source:AC220V,50/60Hz

power:0.5KW

Air source:0.35MPA-0.63MPA

Air consumption:>0.24M%/MIN

Machine size:Length 1100mm wide 820mm high 800mm

Machine weight:55Kg

It is composed of high-quality mechanical components, advanced electrical control systems and precise sensors. The overall structure is reasonably designed, the cooperation between each part is closely coordinated, and it has high stability and reliability.

Equipped with an intuitive and friendly human-machine interface (HMI), operators can complete tasks such as equipment parameter setting, working mode selection, fault information query, etc. through simple touch screen operations, and can master the use of the equipment without complex professional training.

During the design and manufacturing process, we focus on the application of environmental protection and energy-saving concepts, and use energy-saving motors, optimized transmission systems and intelligent energy management technologies to reduce the energy consumption of equipment.

Application areas:

Express logistics companies: can quickly process a large number of express parcels, improve parcel packaging efficiency and quality, and reduce operating costs.

E-commerce enterprise warehouses: express packaging machines can be integrated with e-commerce enterprises' order management systems to achieve automated order processing and parcel packaging.

Postal system: When handling various letters, parcels and mails, the postal department can also use express packaging machines to improve packaging efficiency and standardization.

Internal logistics of large enterprises: Express packaging machines can play a role in the internal logistics centers of these enterprises and automate the packaging of products within the enterprise.