High speed blister packaging machine

1. The use of advanced control systems and precise mechanical structures can achieve long-term continuous and stable operation, reducing downtime and production interruptions.

2. The use of high-precision molds and advanced molding technology makes the blister molding regular and accurate in size, and the error can be controlled within a very small range.

3. By optimizing the heat sealing parameters and using high-quality heat sealing materials, the blister seal is guaranteed to be firm and the product quality is effectively protected.

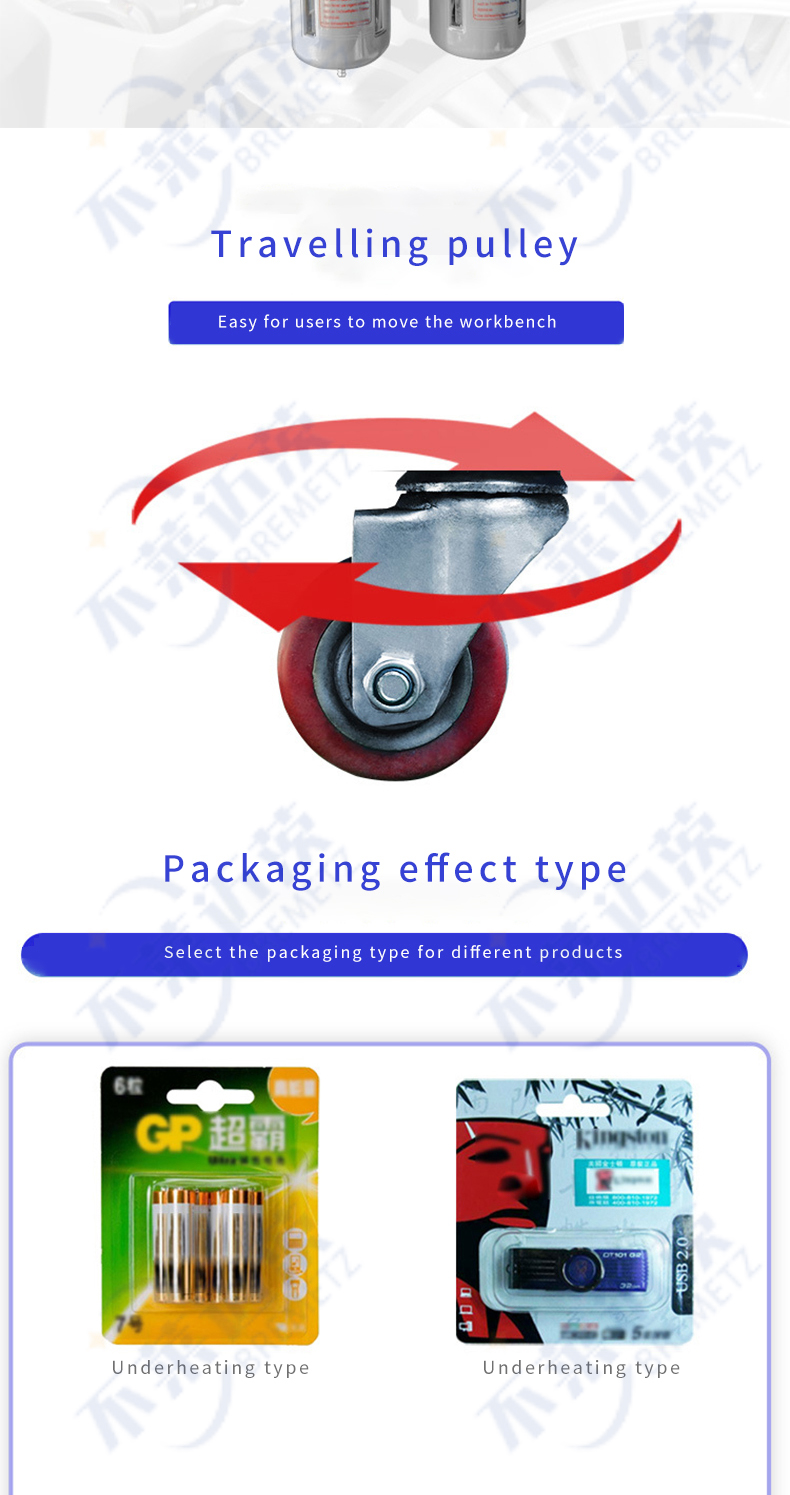

3. It can be used for the packaging of a variety of products and can adapt to products of different shapes, sizes and properties.

4. The traction mechanism of the robotic arm adopts servo drive, and the stroke can be freely adjusted within a certain range.

5. The use of energy-saving motors and advanced control technology reduces the energy consumption of the equipment and saves energy costs.

As a key equipment in the field of modern packaging, high speed blister packaging machine is widely used in many industries such as food, cosmetics, electronics, etc. with its excellent performance. It integrates advanced mechanical manufacturing, automatic control and thermoforming technology, and packages the product between the blister and the base plate with high speed, precision and stable work flow.

The advanced technology of positive pressure forming, vacuum forming or a combination of the two, combined with high-precision molds, can quickly shape regular and accurate blister in a short time. The forming speed is as high as dozens or even hundreds of times per minute, meeting the packaging shape requirements of different products.

Equipped with a variety of feeding devices such as vibrating plates, conveyor belts, metering screws, etc., it can accurately convey and fill products according to their characteristics (such as granules, powders, tablets, liquids, etc.).

Using multiple heat sealing methods such as upper and lower mesh, male and female heat sealing, air cushion heat sealing, etc., combined with precise temperature, pressure, and time control, the blister and the base plate are quickly and firmly sealed. The heat seal has high strength, effectively preventing air and moisture from entering, providing a reliable sealing environment for the product and extending the shelf life of the product.

After the blister forming, filling and heat sealing are completed, the continuous blister sheet is accurately cut into individual packaging units according to the preset size through a high-speed punching mechanism and output in an orderly manner.

The molding process relies on high-precision molds and advanced technology to ensure that the blister molding error is extremely small and the appearance is neat and exquisite; the filling process is precisely measured to prevent product quantity or weight deviation.

The heat sealing process strictly controls parameters and ensures a tight and firm seal, ensuring the quality of each packaging unit is stable and reliable in all aspects, thereby improving the market competitiveness of products.

It is used for product packaging in many fields such as medicine, food, cosmetics, electronics, etc. It can flexibly deal with products in different forms such as tablets, capsules, granules, powders, liquids, blocks, etc.

Equipped with a PLC control system and a human-machine interface, operators can easily complete operations such as equipment start-up, stop, parameter setting, operation monitoring, and fault diagnosis through an intuitive interface, thereby achieving highly automated production, reducing manual intervention, lowering labor intensity, and improving production efficiency.

Energy-saving motors and advanced control technology are used to reduce energy consumption while ensuring high-speed operation. Equipped with multiple safety protection facilities such as emergency stop button, overload protection, safety shield, etc.