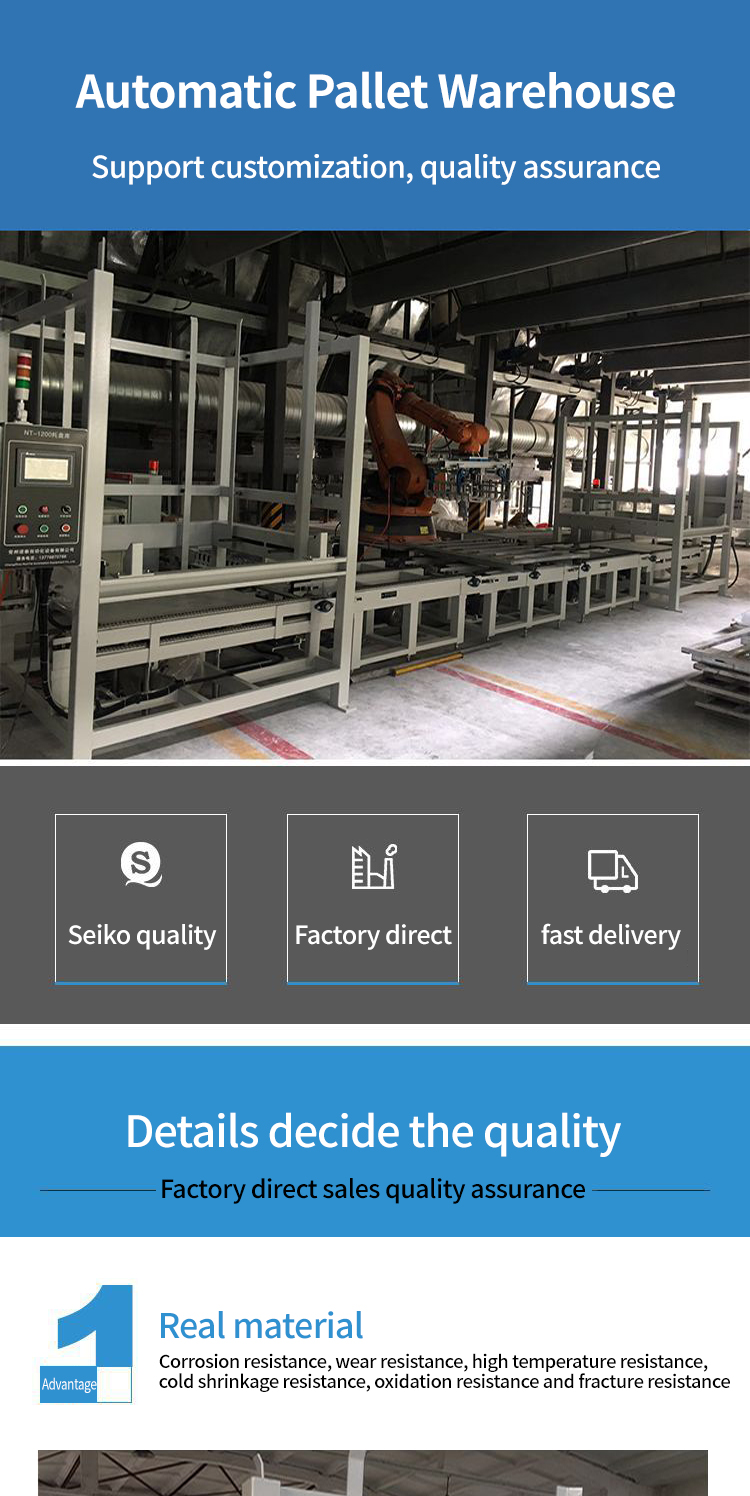

Fully automatic pallet warehouse

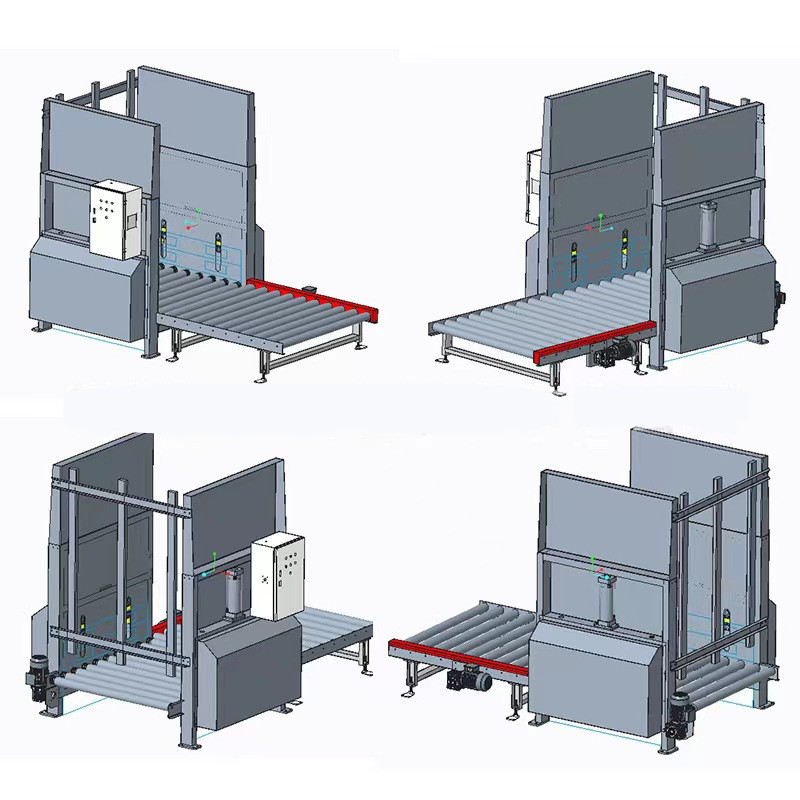

1. Three-dimensional storage: It can build a multi-layer three-dimensional shelf system, make full use of the vertical space of the warehouse, and greatly increase the storage capacity.

2. Compact layout: By rationally planning the shelf layout and pallet storage method, the channel space between shelves can be reduced and the utilization rate of warehouse space can be improved.

3. Automated operation: The use of automated equipment such as stacking cranes and shuttles can realize the automatic storage, retrieval and handling of goods.

4. Continuous operation: The automated equipment can run 24 hours a day, ensuring the continuity and stability of warehouse operations.

5. Accurate storage and positioning: With the help of computer systems and sensor technology, each pallet and cargo can be accurately located and managed, and the information of the cargo can be mastered in real time.

6. Flexible configuration: The system has high flexibility and scalability, and can be adjusted according to the development needs and business changes of the enterprise.

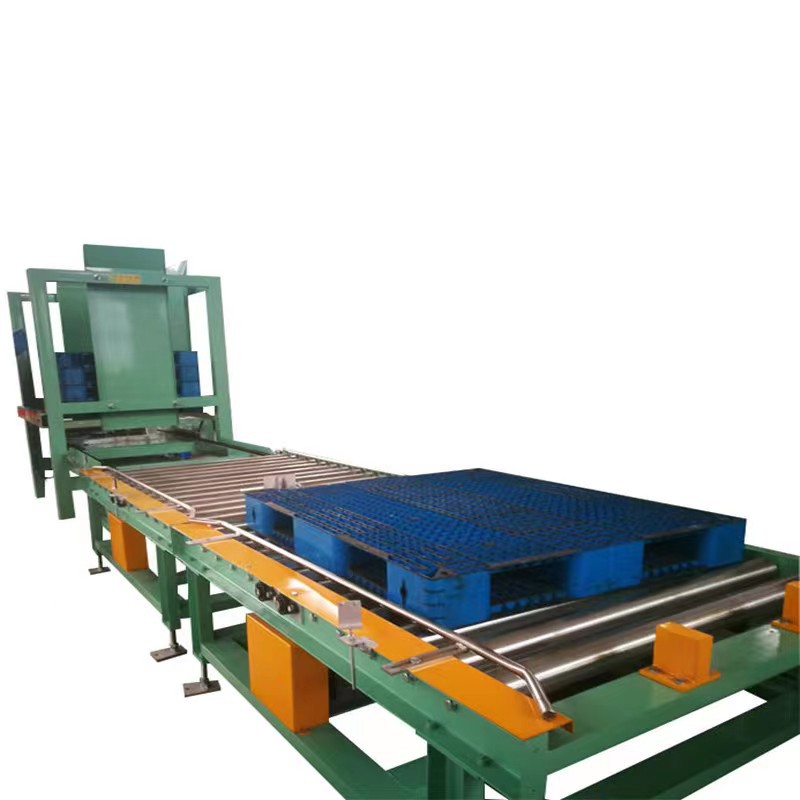

The fully automated pallet warehouse is a highly automated storage system that integrates multiple hardware and software components such as shelves, stacking equipment, conveyor systems, and control systems. It can realize the automatic storage, retrieval, and handling of palletized goods, greatly improving the efficiency and accuracy of storage operations. It is suitable for logistics centers, manufacturing companies, e-commerce warehouses, etc. of various sizes.

Corrosion resistance, wear resistance, high temperature resistance, cold shrinkage resistance, oxidation resistance and fracture resistance.

Reasonable design,Compact structure, multiple specifications, customizable.

High degree of automation: Through the coordinated work of various automated equipment and control systems, automatic storage, retrieval and handling of goods are realized, which greatly reduces manual intervention, improves operation efficiency and accuracy, can quickly respond to order requirements, and shortens the time for goods to enter and leave the warehouse.

Accurate cargo management: With the help of advanced information management systems, the status and location of cargo can be monitored in real time, the inventory quantity and in-and-out records can be accurately grasped, and refined cargo management can be achieved to reduce the occurrence of cargo loss and misplacement.

High operating efficiency: The high-speed operation and continuous operation capabilities of automated equipment, as well as the optimized workflow, greatly improve the speed of cargo in and out of the warehouse, and can quickly respond to market demand and meet the production and sales needs of enterprises.

High safety: Equipped with a variety of safety protection devices, such as anti-collision system, emergency stop button, height and weight limit devices, etc., to ensure the safety of operators and equipment, while also reducing the risk of damage to goods during handling and storage.

Strong scalability: The system has good scalability, and can flexibly increase or decrease hardware facilities such as equipment and shelves, as well as upgrade the software system according to the development of the enterprise and business changes, to achieve the expansion of warehouse scale and improvement of functions.

Fault repair response: Once the equipment fails, customers can contact the after-sales maintenance team in time. Professional technicians will respond in a short time, through telephone communication, remote diagnosis or on-site repair.

Parts replacement: The after-sales team will provide genuine parts replacement services to ensure that the replaced parts are fully compatible with the equipment and guarantee the performance and reliability of the equipment.

Technical consultation: If customers encounter any technical problems during use, they can consult the after-sales technical support team at any time. With rich professional knowledge and experience, the technicians will provide customers with detailed answers and technical suggestions to help customers solve problems and optimize the use of the equipment.

System upgrade and optimization: With the continuous development of technology and changes in customer business needs, the after-sales team will provide customers with system upgrade and optimization services to ensure that the equipment always maintains advanced performance and functions, better meet customer business needs, and improve customer competitiveness.