Intelligent perception collaborative robot

1. Multi-dimensional perception capability: The intelligent perception collaborative robot is equipped with a variety of advanced sensors that can accurately identify the shape, size, color and position of objects. Whether in a complex production environment or facing objects of different shapes, it can quickly and accurately locate them.

2. High-precision operation execution: Based on accurate perception data, the robot can achieve high-precision operations. The motion control system of its robotic arm can convert the perceived information into precise action instructions to control the robot's movements at the micron level.

3. Environmental perception ensures safety: The robot can perceive the surrounding environment in real time, including the position and movement of personnel and the situation of other obstacles. Through complex algorithms and sensor data fusion, when it detects the risk of collision with personnel or other objects, it will immediately adjust its movement speed, direction or stop the action.

4. Optimize the collaborative process to improve efficiency: The intelligent perception collaborative robot can form an efficient collaboration mode with human operators. It can understand human action intentions and workflows and automatically adapt to the work rhythm of different operators.

5. Strong task adaptability: Whether it is a simple and repetitive handling task or a complex assembly task, the intelligent perception collaborative robot can do it. It can quickly adjust the working mode through programming and learning algorithms to adapt to different task requirements.

6. Wide environmental adaptability: Robots can work in a variety of complex environments, such as high temperature, low temperature, humid, dusty industrial environments, or production workshops with limited space and complex layouts

7. Intelligent learning and upgrading: Using the collected data, robots can perform intelligent learning. At the same time, manufacturers can upgrade the software and hardware of robots based on a large number of user data feedback, provide users with continuously improved functions and performance, extend the service life of robots and increase their value.

The intelligent sensing collaborative robot is an advanced automation device that integrates cutting-edge technology, and is designed to provide efficient, accurate and safe collaborative solutions for industrial production, logistics warehousing, scientific research experiments and other fields. It perfectly combines intelligent sensing technology with collaborative functions, becoming a powerful assistant in modern intelligent production environments.

It has a highly reliable safety collaboration mode and can work safely with human operators in the same workspace. When the robot detects that the distance to people or other objects is close to the safety threshold, it will automatically reduce the running speed or pause the action. Its safety protection system complies with international safety standards and adopts multiple safety technologies such as collision detection, area monitoring, and safety light curtains to ensure the safety of personnel and the integrity of equipment during human-machine collaboration.

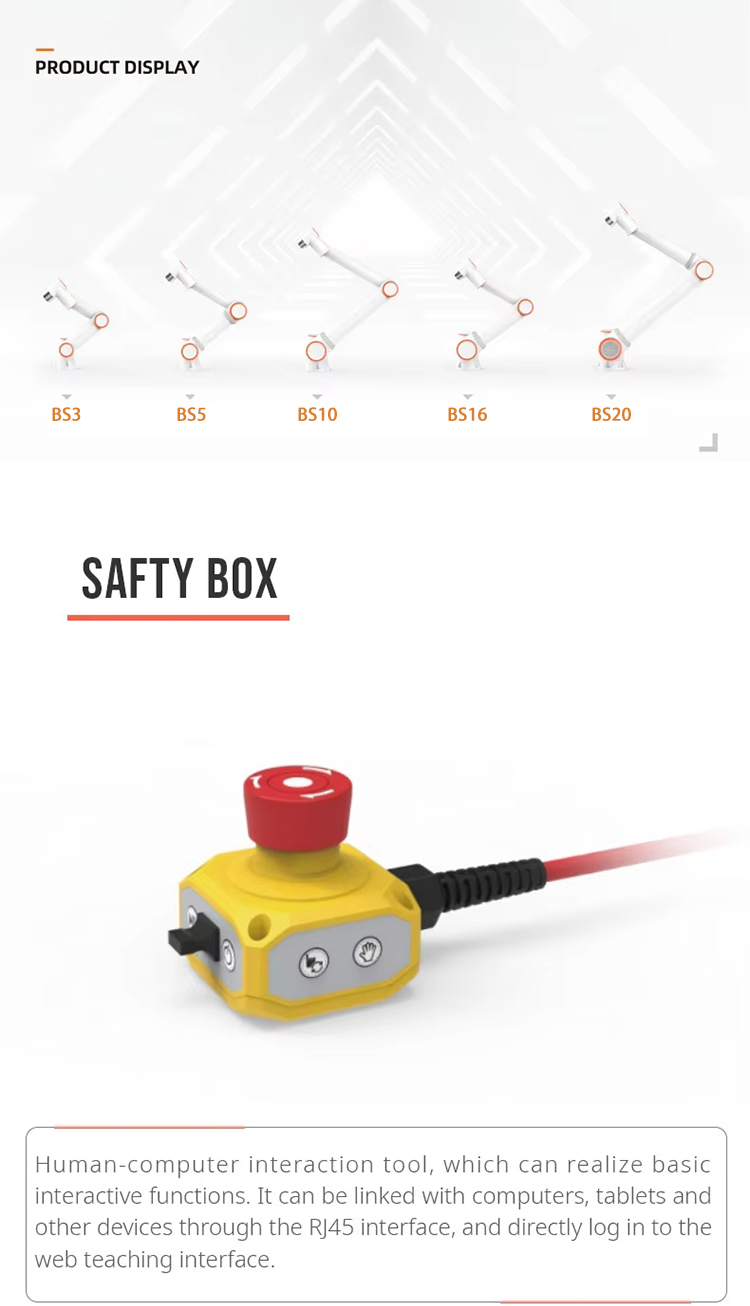

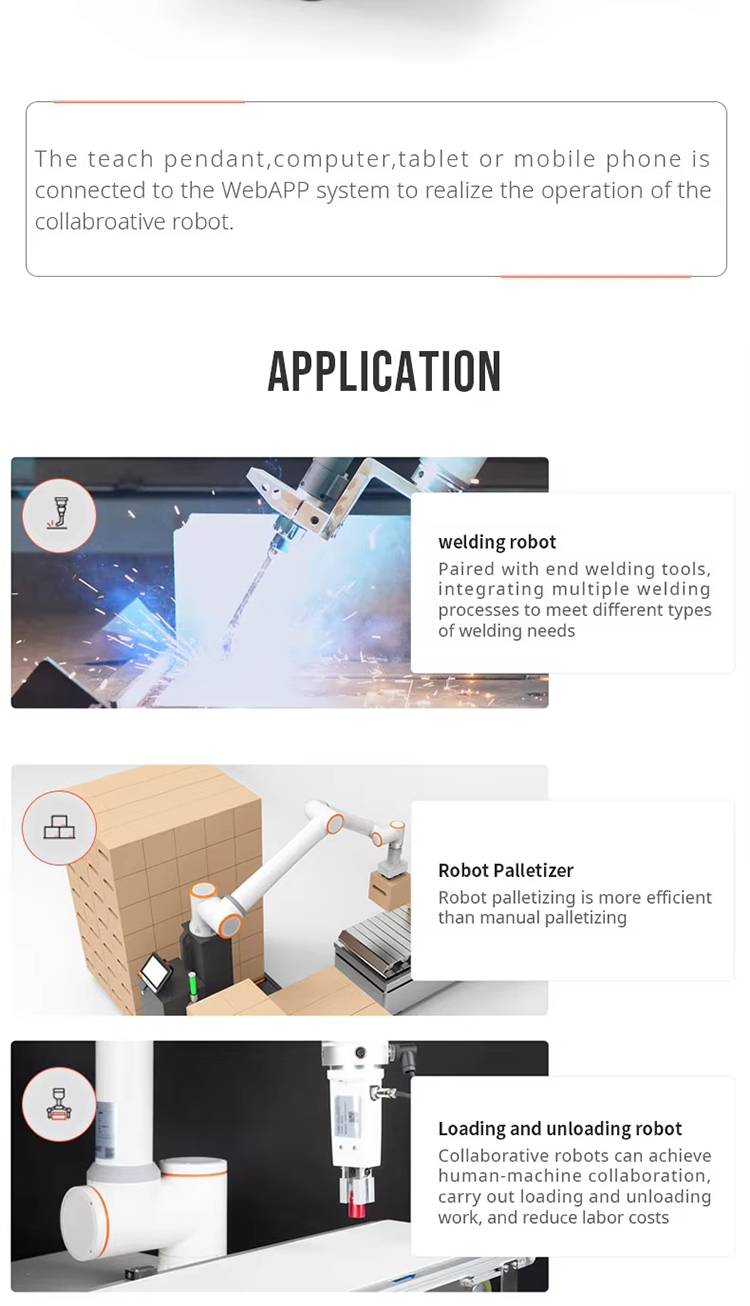

A convenient human-machine interaction interface and multiple interaction methods are designed. Operators can operate and program the robot through teaching pendants, gesture recognition, voice commands, etc. The robot can quickly understand human intentions and accurately perform tasks according to instructions. In addition, it can automatically adjust the collaboration mode according to the operator's working habits and rhythm, realize seamless cooperation between man and machine, and improve work efficiency.

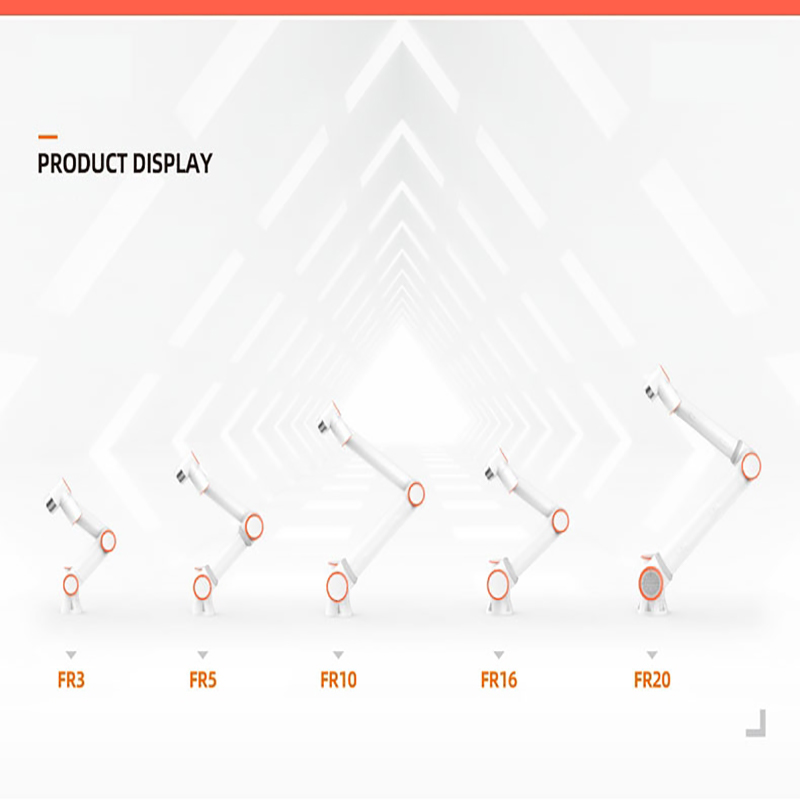

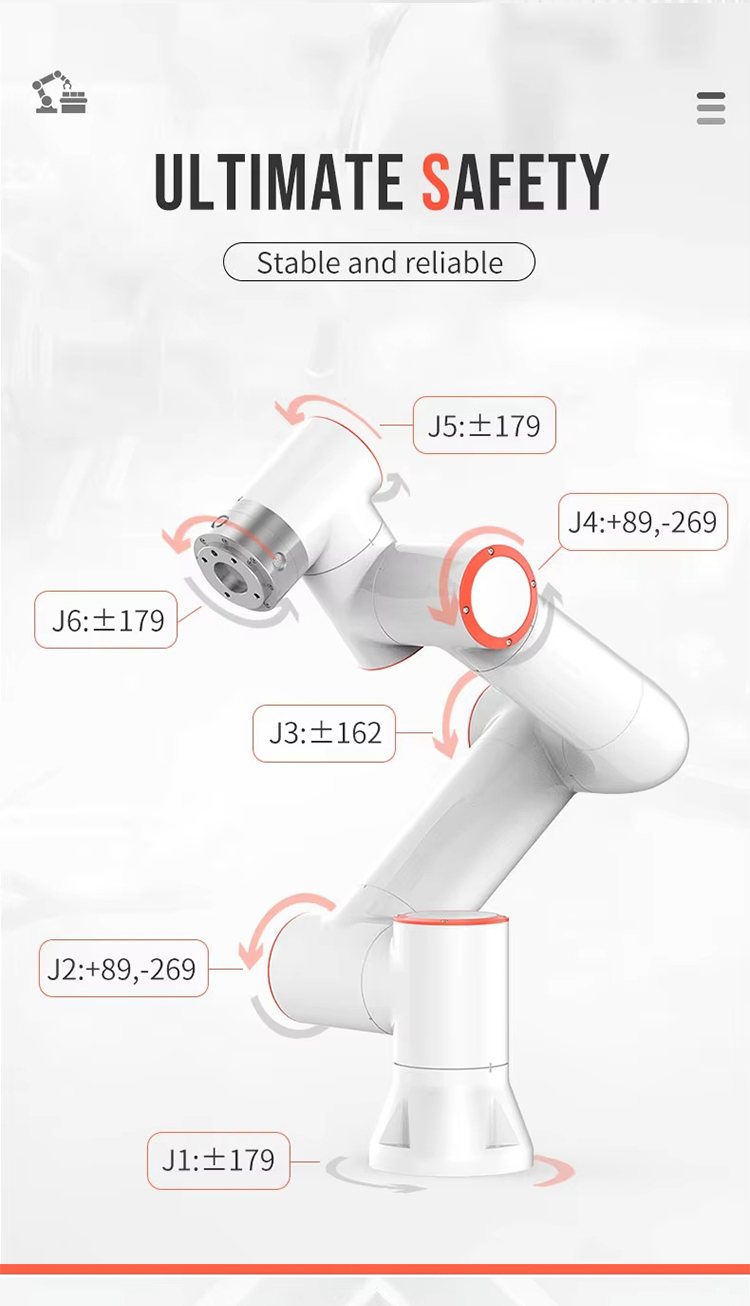

The high-precision mechanical arm and joint design adopts high-strength, lightweight materials and advanced manufacturing technology to ensure the rigidity and stability of the mechanical structure. The mechanical arm has a wide range of motion and can flexibly reach various positions in the working area to meet different operating requirements.

Application areas:

Industrial manufacturing, in the automotive manufacturing, electronic equipment production, mechanical processing and other industries, it is used for the assembly, handling and testing of parts and components.

Logistics warehousing, in logistics distribution centers and warehouses, it can realize the rapid sorting, stacking and handling of goods. The robot can accurately pick the goods according to the order information and neatly stack them on pallets or load them into transport vehicles, which greatly improves the automation and efficiency of logistics operations.

Scientific research experiments, in laboratory environments, assist researchers in experimental operations such as sample processing and instrument operation. Its high precision and intelligent perception capabilities can ensure the accuracy and repeatability of the experimental process, while preventing researchers from contacting dangerous experimental materials or environments.

Health care, in the medical field, it can be used to assist surgery, rehabilitation treatment and drug distribution.