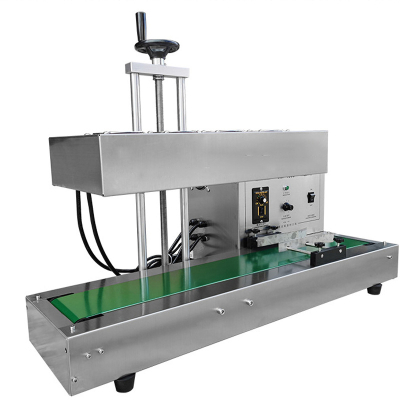

Granule Packaging Machine

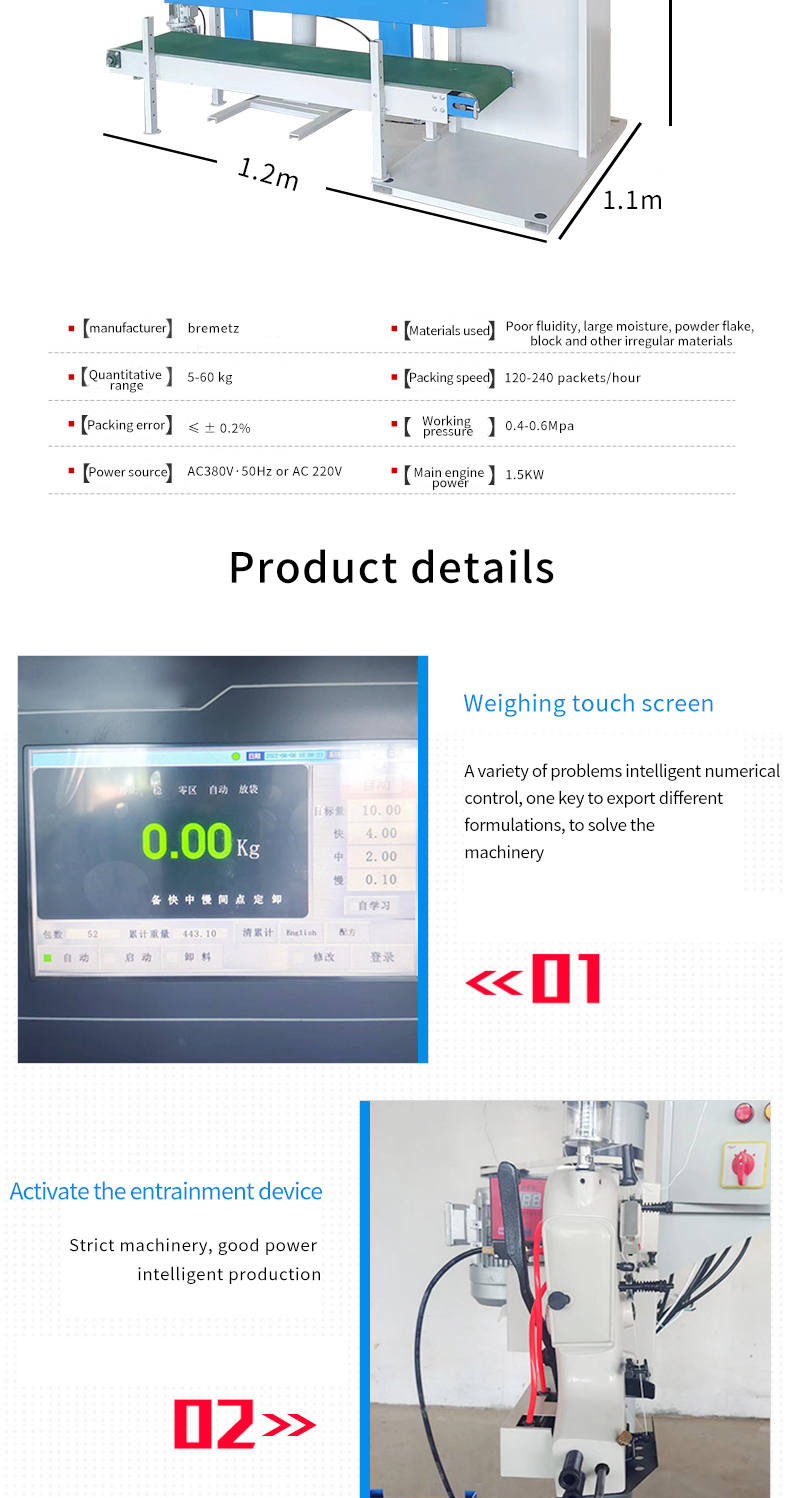

1. The use of high-precision electronic weighing systems, volumetric metering devices or spiral metering devices can accurately measure granular materials.

2. Some machines have functions such as automatic correction of drop and automatic tracking of zero points, and can adjust the metering parameters in real time according to the actual packaging situation.

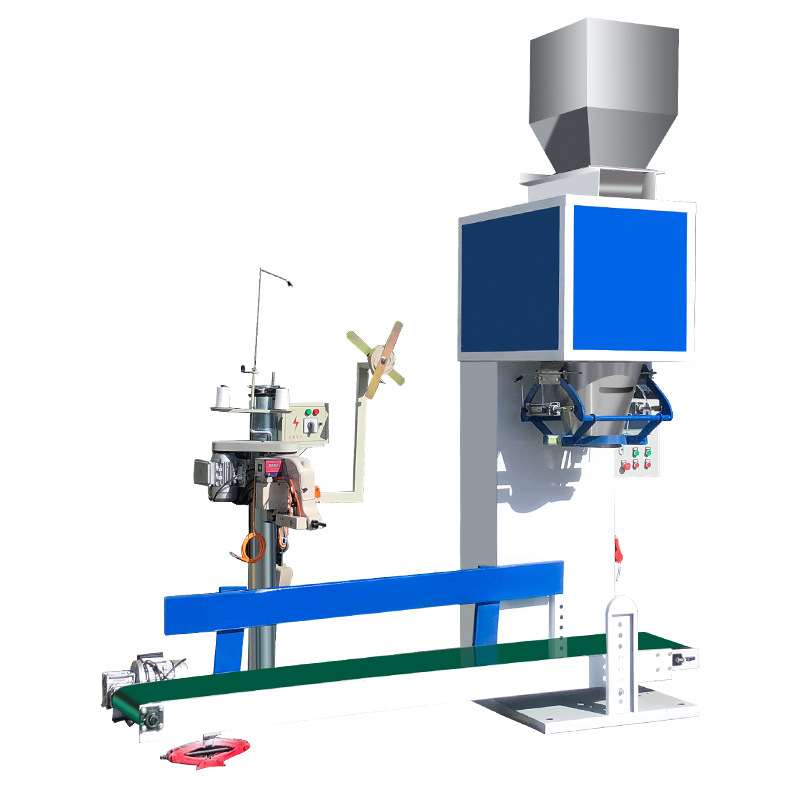

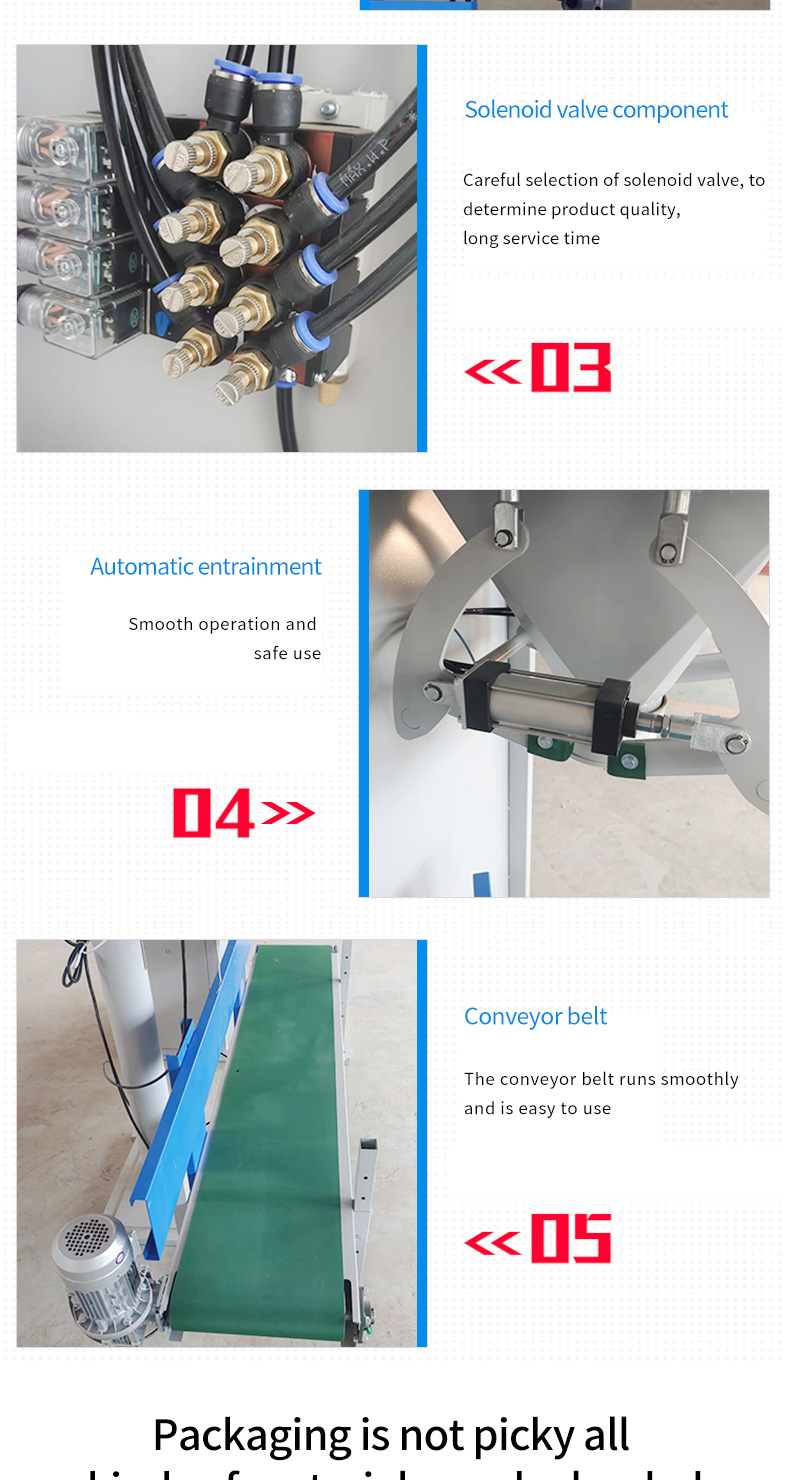

3. The fully automatic granule packaging machine can automatically complete the entire packaging process from material conveying, metering, filling, bag making, sealing, printing production date to finished product output.

4. It can be used to package various granular materials, and can also adapt to the packaging needs of materials with different particle sizes, shapes, fluidity and specific gravity.

5. By adjusting the machine parameters and replacing some parts, it can adapt to different packaging specifications and meet the diverse needs of different customers and markets.

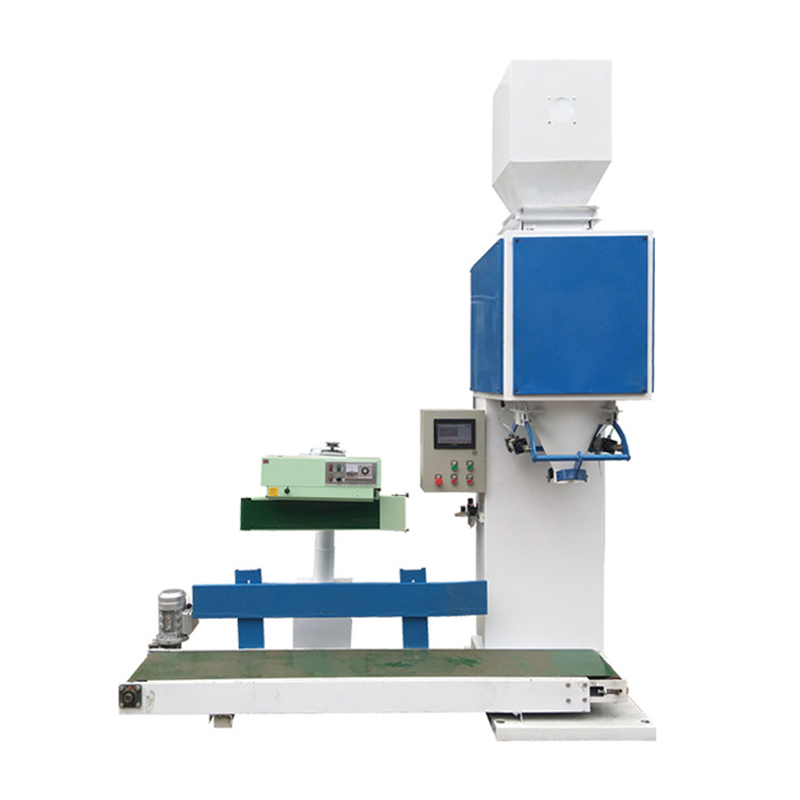

Granule Packaging Machine is an advanced equipment specially used for packaging granular materials, which plays a key role in many industries.Its overall appearance usually adopts a simple and elegant industrial style design, and the main structure is composed of a sturdy and durable metal frame to ensure stability under long-term and high-intensity work.

With advanced metering technology and automatic compensation algorithms, the metering error of granular materials can be controlled within a very small range. Whether it is tiny coffee particles or larger plastic particles, they can be packaged accurately to meet the quality requirements of different products.

The fully automatic operation process greatly increases the packaging speed, and dozens or even hundreds of bags can be packed per minute, which greatly improves production efficiency, saves a lot of time and costs for enterprises, and adapts to the needs of large-scale industrial production.

It is suitable for granular products in many industries such as food, medicine, chemical, feed, plastic, etc. It can handle materials with different particle sizes, shapes, fluidity and specific gravity, and can easily adjust the packaging specifications.

It uses high-quality parts, precise mechanical structure, stable operation and low failure rate. At the same time, the perfect fault detection and alarm system can detect and prompt problems in time, facilitate rapid maintenance and ensure production continuity.

It uses high-quality parts, precise mechanical structure, stable operation and low failure rate. At the same time, the perfect fault detection and alarm system can detect and prompt problems in time, facilitate rapid maintenance and ensure production continuity.

The parts in contact with materials are made of food-grade or pharmaceutical-grade materials, which are easy to clean and disinfect to prevent material contamination. They are also equipped with safety devices such as overload protection and leakage protection to ensure the safety of operators and equipment.