Fully automatic powder filling production line

1. High-speed operation: It can continuously perform powder filling operations at a faster speed, greatly improve production efficiency, meet the needs of mass production and the market's requirements for rapid product delivery.

2. Multi-station collaborative operation: The entire production line cooperates with each station, and the loading, metering, filling, sealing, packaging and other links are seamlessly connected, reducing waiting time and pauses in the production process.

3. High-precision sensor: Equipped with an advanced metering system, it can accurately control the filling volume each time to ensure that the weight error of each bag or bottle of powder product is extremely small.

4. Intelligent feedback adjustment: Some advanced production lines also have intelligent feedback adjustment functions, which can automatically adjust the filling parameters according to the metering data monitored in real time, further improving the metering accuracy.

5. Parameter preset and storage: The filling parameters of a variety of different products can be pre-set and stored, and the switching is fast and convenient, which improves the flexibility and adaptability of the production line.

6. Stable operating performance: Each component has been carefully designed and strictly screened, the mechanical structure is solid and stable, and the electrical system performance is reliable, ensuring that the production line maintains a stable working state during long-term operation.

7. Closed production environment: The production line usually adopts a closed structural design, which reduces the flying and leakage of powder during the filling process, avoids the health hazards of dust to operators and the pollution of the production environment.

Fully automatic powder filling production line is a highly automated and integrated production system, which is specially used for filling operations of powder products. It is widely used in many industries such as food, medicine, chemical industry, cosmetics, etc. It provides a comprehensive solution for efficient, accurate and safe filling and packaging of powder products, and is an indispensable key equipment in modern production.

Application areas:

Food industry, in the food industry, it is widely used for the filling and production of various powdered foods. These food powders have extremely high requirements for metering accuracy, hygiene standards and packaging quality. The fully automatic powder filling production line can meet these requirements and ensure the quality and safety of the products.

Pharmaceutical industry, for the filling of pharmaceutical powders, the production line can guarantee accurate metering and strict hygiene conditions. The high-precision metering and safe and hygienic design of the fully automatic powder filling production line meet the strict specifications of the pharmaceutical industry.

Chemical industry, many powder raw materials and finished products in the chemical industry need to be filled and packaged. The fully automatic powder filling production line can handle powders of different chemical properties and adapt to the diversified needs of the chemical industry.

In addition to the above industries, the fully automatic powder filling production line can also be applied to other fields that require powder filling, such as the building materials industry, agriculture, etc., to provide efficient and convenient filling solutions for the production of powder products in these industries.

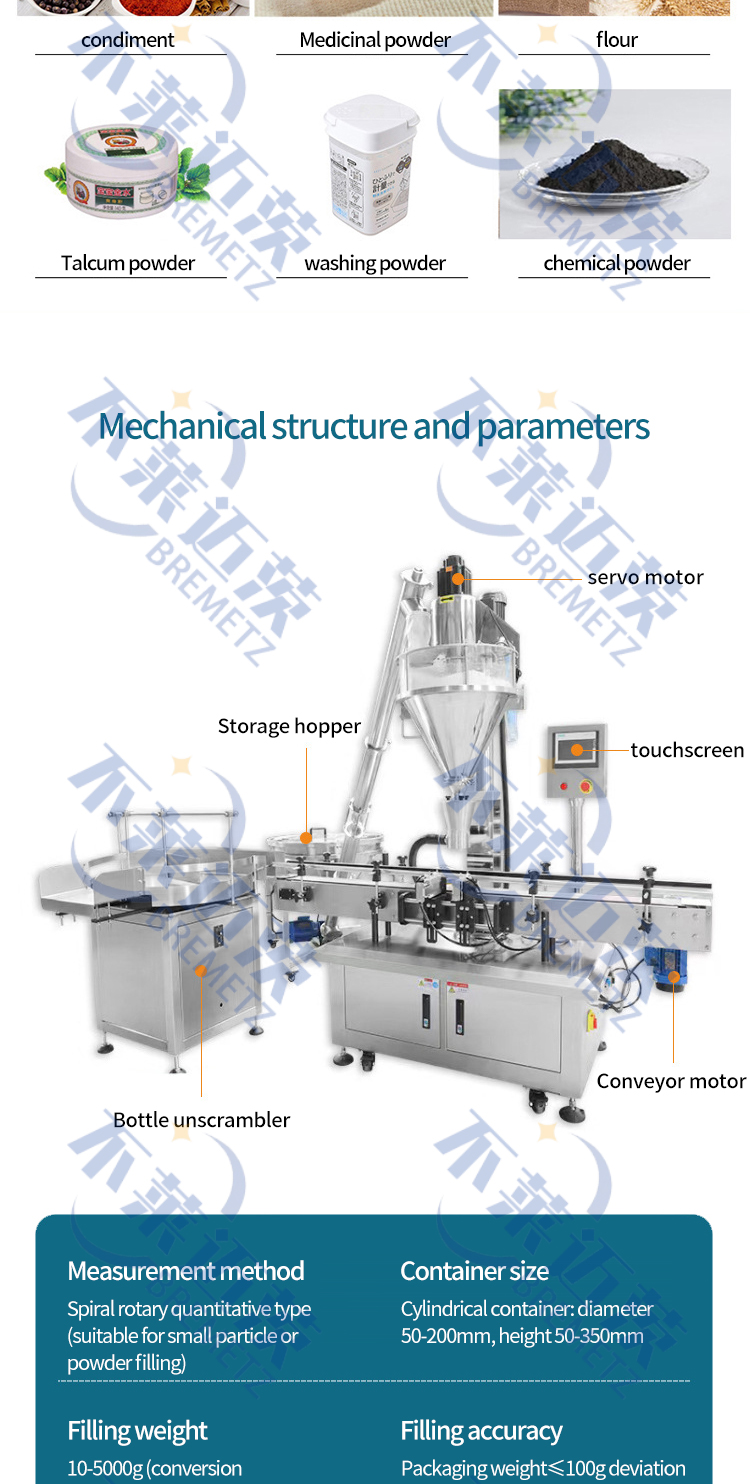

Measurement method:Spiral rotary quantitative type (suitable for small particle or powder filling)

Container size:Cylindrical container: diameter50-200mm, height 50-350mm

Filling weight:10-5000g (conversionspiral attachment)

Filling accuracy:Packaging weight≤100g deviation,<±1g>100g deviation≤±1%

filling speed:10-30 filling/minute

Power Specifications:Three items 380V50-60Hz

Total power:2KW

Total Weight:300Kg

Overall dimensions :(L)3000 x (W)800 x (H)2200mm

Raw material conveying device: Choose the appropriate conveying method according to the physical properties of the powder and the production scale. For example, for fine powder with good fluidity, the pneumatic conveying system uses airflow to transport the powder from the storage bin to the production line, and its conveying pipeline is equipped with a filter device to prevent powder leakage; for powder with poor fluidity or easy to agglomerate, the screw conveyor pushes the powder forward through the rotating spiral blades, and can be equipped with a stirring device to prevent the powder from agglomerating.

The production line uses high-quality mechanical parts and electrical components, and has undergone strict quality inspection and durability tests. The mechanical structure is reasonably designed, and the connections between the various components are firm and reliable, which reduces the vibration and wear of the equipment during operation. The electrical system is stable and has strong anti-interference ability. It can operate stably for a long time in a complex industrial environment, reducing the failure rate of the equipment and ensuring the smooth progress of production.

We have a professional after-sales maintenance team that can respond promptly to user fault reports. Our maintenance personnel have rich maintenance experience and professional knowledge and can quickly diagnose and solve equipment problems.