Small sealing packaging machine

1. Small size, compact design, does not take up too much space, and is convenient to place in various production sites or commercial shops.

2. Light weight, easy to carry and transfer to the place of use, and can flexibly adjust the position according to actual needs.

3. Equipped with a simple and intuitive operation interface, operators can quickly master its use without complex training.

4. Quick start, can enter the working state in a short time, reduce waiting time, and improve production efficiency.

5. Can achieve accurate and stable sealing effect, effectively prevent the contents in the package from leaking, getting damp, oxidized or contaminated.

6. It has good compatibility with packaging materials of different types and thicknesses, and can flexibly select suitable packaging materials for sealing packaging according to product characteristics and packaging requirements.

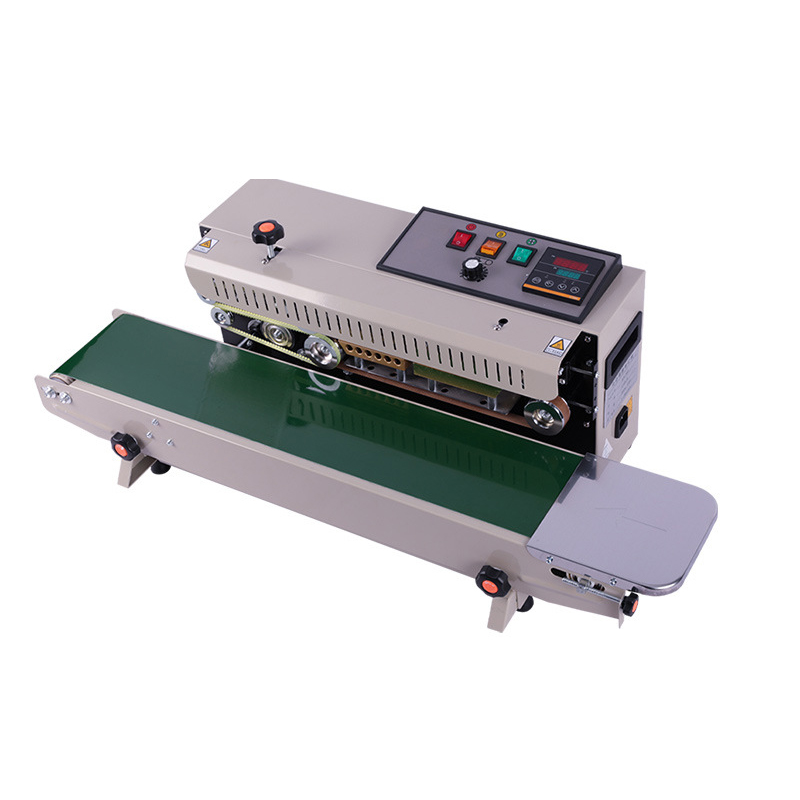

The small sealing packaging machine adopts a compact and sturdy metal frame structure with an exquisite and compact overall shape. It is designed to meet the needs of small enterprises, shops and family workshops for efficient and convenient sealing packaging of various items.

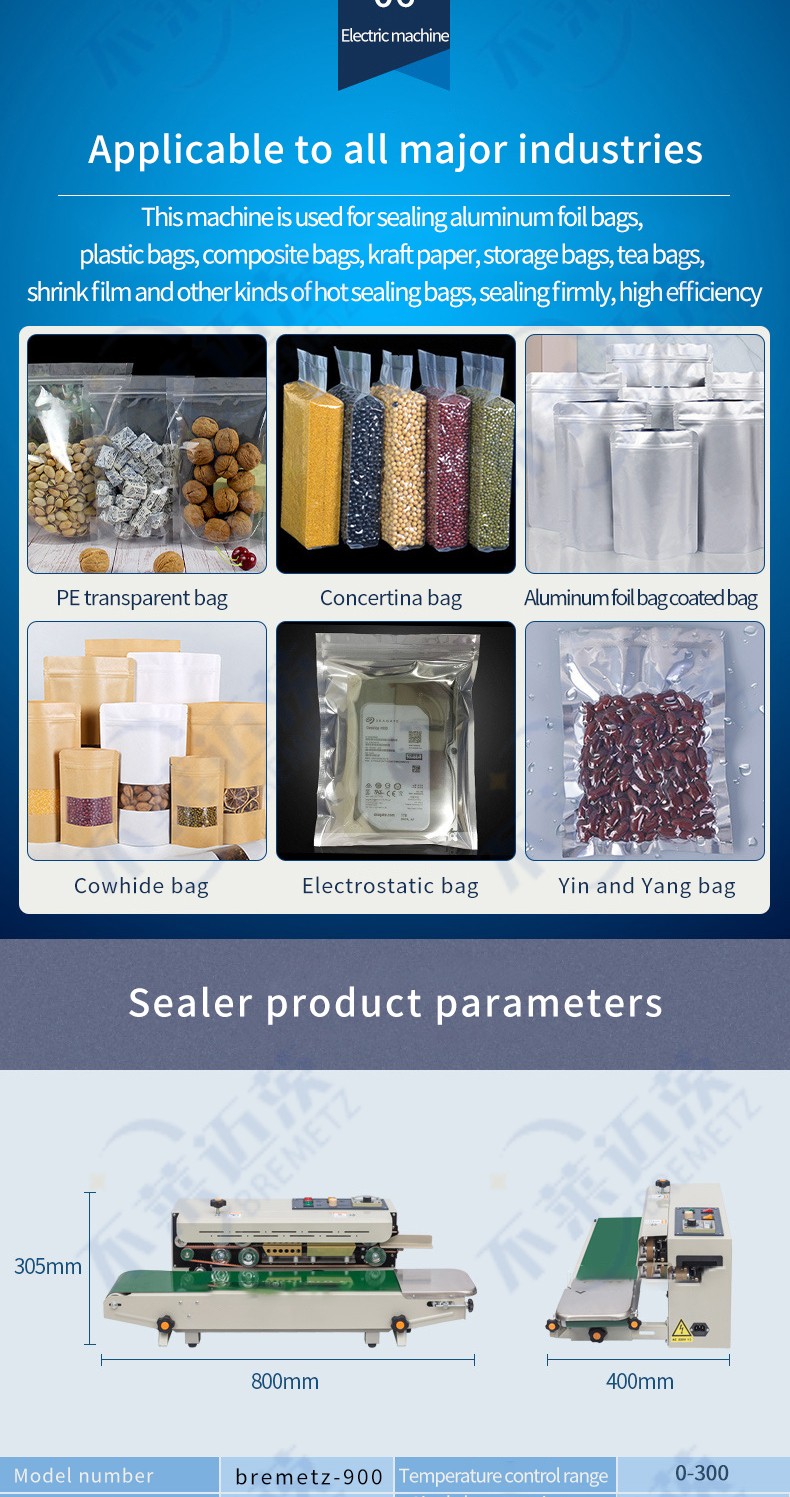

With advanced sealing systems and diversified functional modules, it is able to achieve precise sealing of packaging materials of different types and thicknesses, ensuring a firm and tight seal whether it is plastic film, aluminum foil or composite material.

It supports various packaging forms such as ordinary sealing, vacuum packaging, and inflation packaging, and can be flexibly selected according to product characteristics and packaging needs. It meets the diversified packaging requirements of multiple industries such as food, pharmaceuticals, cosmetics, and electronics, and expands the application scope and market adaptability of the product.

It adopts advanced microcomputer control system and integrates intelligent operation interface. Users can easily set various parameters such as sealing temperature, time, pressure, vacuum degree, inflation volume, etc. through simple key operation or touch screen input.

Energy saving and environmental protection factors were fully considered during the design process, and energy-saving heating elements, motors and optimized circuit design were adopted to effectively reduce the energy consumption of the equipment.

The overall structure is compact, small in size, light in weight, and does not take up too much space. It is convenient to place in various production sites, commercial shops or home environments, and is easy to carry and move to the location of use. The position can be flexibly adjusted according to actual needs.

Model number:bremetz-900

Temperature control range:0-300

Power source:220V50HZ

Single layer maximum film thickness (mm):≤0.08

power:0.65KW

Sealing width (mm):12

Sealing speed (m/min);0-12

Overall dimensions (mm):800*400*305

The structure of the equipment is relatively simple, the parts are easy to replace and maintain, the maintenance difficulty and cost are low, and the daily maintenance work mainly focuses on cleaning, lubrication, inspection of wearing parts, etc., which can be completed by general users themselves or solved through simple after-sales service support.

For some simple faults, our technicians will provide assistance to customers through remote technical support. Using tools such as video calls and remote desktop connections, they will guide customers to check, debug and troubleshoot equipment.

With the continuous development of science and technology and the advancement of industry technology, we will continue to pay attention to the update and upgrade of small sealing packaging machine related technologies, and provide customers with technical upgrade services and guidance in a timely manner.

We attach great importance to customer feedback and user experience, and have established a variety of customer feedback channels to facilitate customers to communicate with us.