Automatic winding machine

1. The automatic winding machine is equipped with an advanced tension control system, which monitors the tension of the winding material in real time through a high-precision tension sensor. The tension error is precisely controlled within a very small range.

2. The use of advanced motion control systems and precise transmission mechanisms can achieve precise position control of the wound object.

3. The automatic winding machine has a powerful power system and an optimized winding mechanism design, which can achieve high-speed winding operations.

4. The equipment has a high degree of automation and can automatically detect and handle some common operating faults, such as material jams, abnormal tension, etc.

5. The operator only needs to simply set the winding parameters on the human-machine interface of the equipment to automatically start and complete the entire winding operation.

6. It integrates an advanced intelligent control system, which can monitor the operating status and process parameters of the equipment in real time, and make intelligent adjustments according to preset programs and algorithms.

Automatic wrapping machine is a highly automated and intelligent mechanical equipment, widely used in many fields such as industrial production, logistics packaging, etc. It can accurately and efficiently wrap objects of various shapes, sizes and materials.

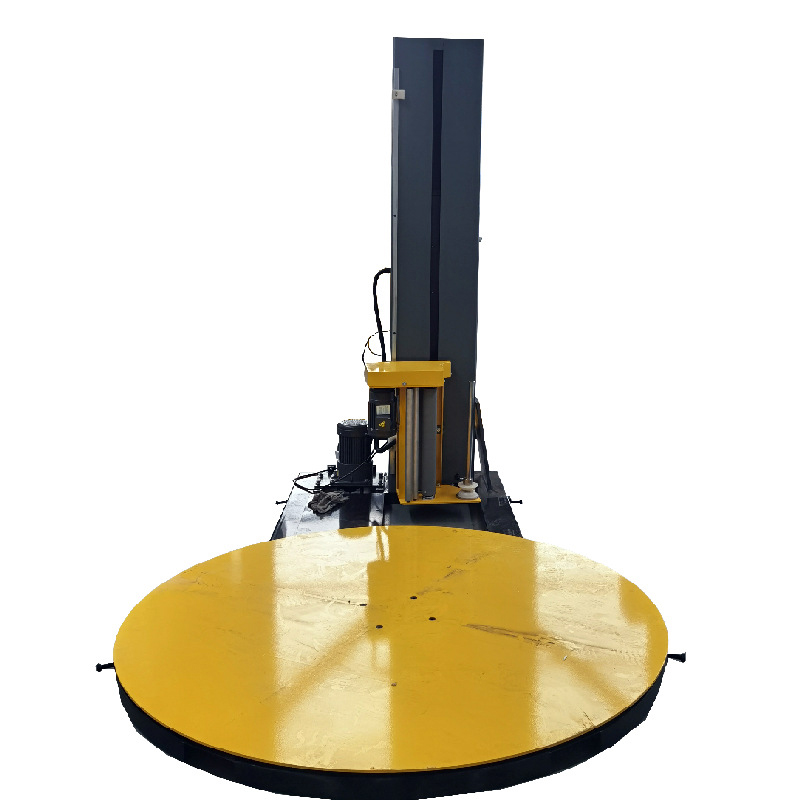

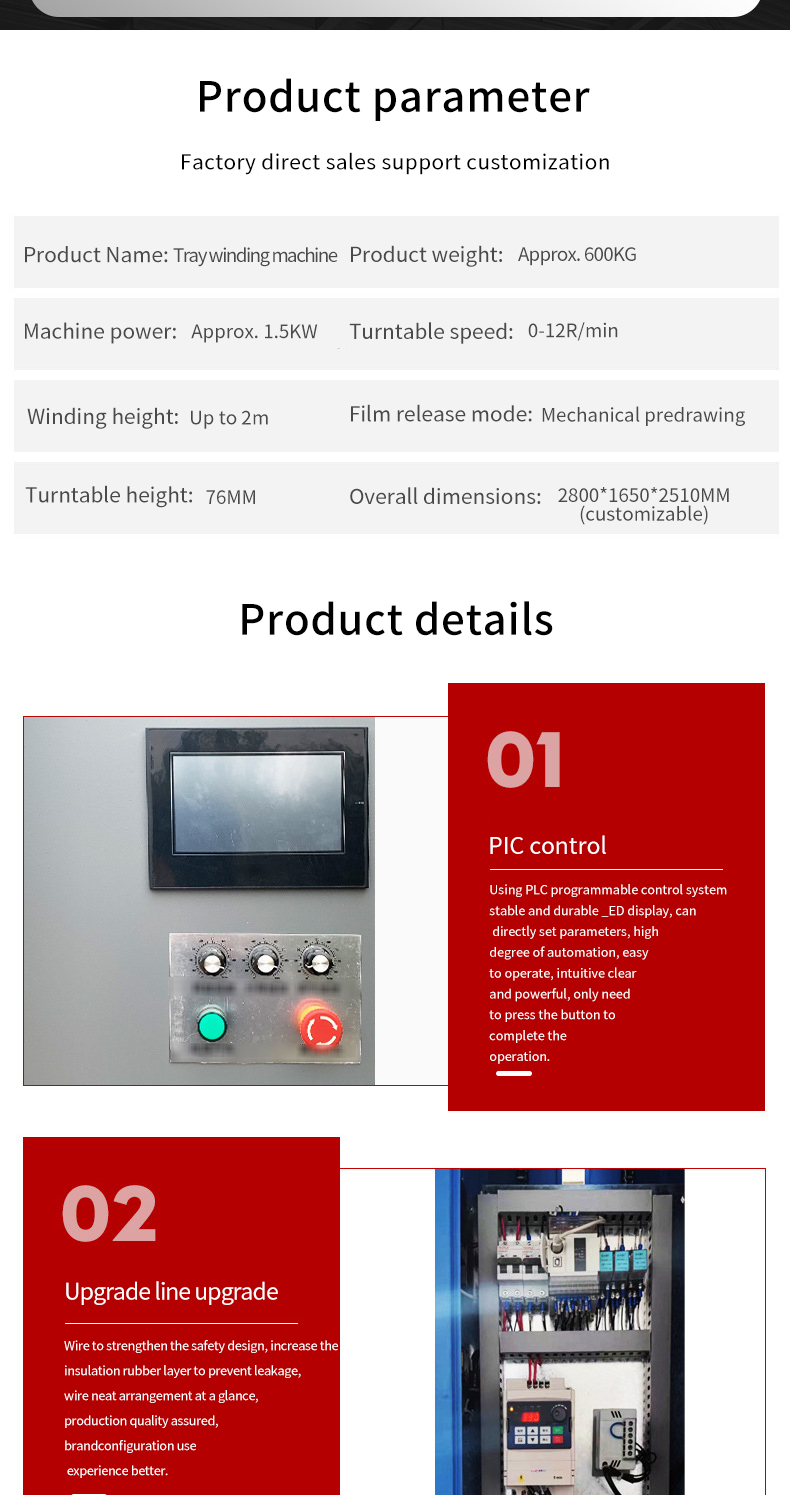

Product Name: Tray winding machine

Product weight:Approx. 600KG

Machine power: Approx. 1.5KW

Turntable speed: 0-12R/min

Winding height: Up to 2m

Film release mode: Mechanical predrawing

Turntable height: 76MM

Overall dimensions: 2800*1650*2510MM (customizable)

The automated operation process and high-speed winding capabilities give it significant advantages in production efficiency. Compared with traditional manual or semi-automatic winding methods, automatic winding machines can significantly shorten the winding time of a single product.

The control system with PLC as the core has powerful intelligent functions. It can automatically adjust the operating parameters of the equipment according to different winding tasks and material characteristics, such as automatically adjusting the tension according to the thickness change of the winding material.

It can adapt to the winding needs of objects of various shapes, sizes and materials, as well as different types of winding materials. By replacing different fixtures, molds and adjusting equipment parameters, it can easily realize the winding packaging of various materials.

The use of high-quality mechanical parts, advanced electrical components and strict quality inspection processes ensures that the equipment has stable and reliable performance during long-term operation. The mechanical structure is sturdy and durable and can withstand high-intensity workloads.