Paste filling machine

1. Accurate metering method: For example, the paste filling machine using piston-type volumetric metering can accurately control the filling volume each time. For paste products that require accurate dosage, it can ensure that the content of each bottle or each product meets the standard requirements.

2. Small error range: Advanced paste filling machines have been carefully adjusted and optimized, and the filling error can be controlled within a very small range, ensuring the consistency and quality stability of the product.

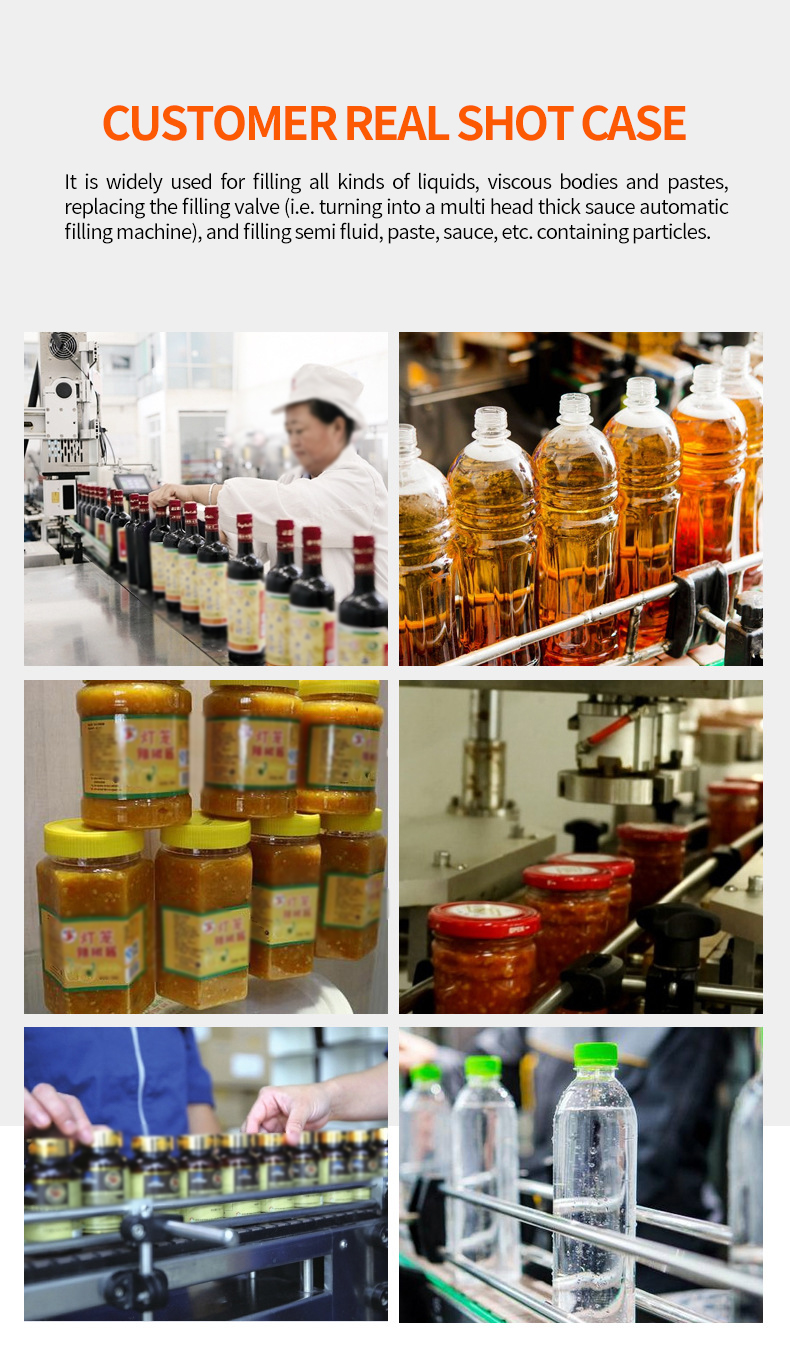

3. Various paste types: Whether it is sauce, toothpaste, or lotion, shampoo and other paste products with different viscosities and fluidities, the paste filling machine can adapt well and accurately fill.

4. Diverse packaging containers: It can be applied to a variety of packaging containers, such as plastic bottles, glass bottles, hoses, barrels, etc., to meet the needs of different customers for product packaging forms.

5. Fast filling: Paste filling machines with a high degree of automation can complete a large number of filling tasks in a short time, greatly improving production efficiency.

6. Friendly human-machine interface: Modern paste filling machines are equipped with intuitive and easy-to-understand human-machine interface. Operators only need simple training to easily master the operation of the machine, which greatly reduces the requirements for the operator's skill level.

7. Excellent material: Parts in contact with the paste are usually made of stainless steel and other materials that meet the hygiene standards of the food and pharmaceutical industries. They are not easy to rust and are corrosion-resistant, which can ensure that the paste product is not contaminated during the filling process.

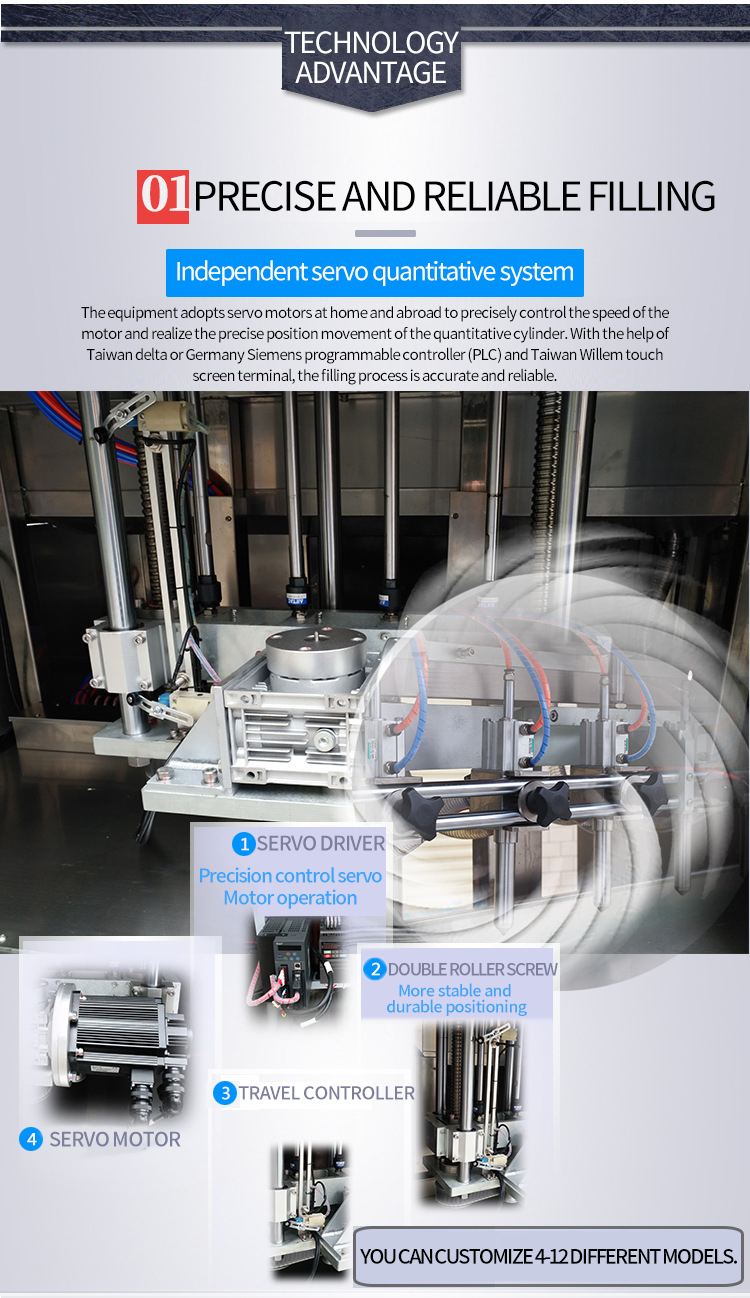

Automatic paste liquid filling machine, multi-head piston type automatic liquid filling machine is a new generation of automatic filling machine developed by our company for many years of production experience and absorbing advanced technology.

Automatic paste liquid filling machine, it adopts piston quantitative principle, electrical appliances and pneumatic components using well-known brands, novel design, beautiful appearance, friendly interface, strong adaptability, simple operation, accurate filling volume, convenient maintenance and other characteristics.

Technical parameters:

Number of heads: 2, 4, 6, 8, 10, 12,

Output (bottles/hour): 600-800, 1300-1600, 1600-2200, 2000-2500, 2500-2800, 3000-3500

Compatible capacity (g): 100-500

Whole line power (Kw): about 4-5, about 6-7, about 8-9, about 10-11

Whole line size (LxWxH) mm: 6000X1500x2000, 8000X1500X2500, 10000X1500x2500, 12000X1500X2500, 14000X1500x2500

16000X1500x2500

Voltage (V) :380

Other features of automatic paste liquid filling machine:

(1) The use of good brands of electrical appliances and pneumatic components, low failure rate, reliable performance, long service life.

(2) The use of high-strength stainless steel frame, easy to disassemble, easy to clean, in line with GMP requirements

(3) The filling volume and filling speed adjustment are simple and the appearance is beautiful

(4) Equipped with no bottle and no filling function, liquid level automatic control and feeding;

(5) Without the need to replace parts, you can quickly adjust a variety of different shapes and specifications of the bottle;

(6) The filling head is equipped with a special leak-proof device, and there is no brushing and dripping phenomenon in filling.

The frame of the equipment is made of high-strength metal materials, such as high-quality steel, and is precisely cut and welded to ensure the stability of the overall structure. This sturdy frame can effectively bear the various pressures and vibrations during the filling process, ensuring that the equipment remains stable during long-term operation and that the filling accuracy will not decrease due to external forces.

The equipment is equipped with a high-precision piston device, which accurately controls the filling amount of the paste through the reciprocating motion of the piston. The stroke of the piston can be accurately adjusted according to the set filling amount to ensure that the dosage of each filling is accurate. This metering method has high metering accuracy for high-viscosity pastes, such as ointments, meat sauces, etc., and the error can be controlled within a very small range.

After filling is completed, the equipment can quickly and effectively cut off the flow of the paste to prevent the paste from dripping outside the container. This is achieved through a specially designed filling head valve and control system, which ensures that the paste channel is closed at the moment the filling is completed to avoid wasting the paste and polluting the working environment. At the same time, for pastes with high viscosity and easy to draw, the special design of the equipment can effectively prevent the drawing phenomenon, ensuring that the appearance of the product after filling is neat and beautiful.

In food processing enterprises, it is used to fill various paste foods, such as jam, peanut butter, chocolate sauce, cream, etc. Through precise filling, it ensures that the weight and quality of the product meet the standards and meet the consumer's requirements for food quality. At the same time, the hygienic design of the equipment ensures the safety and hygiene of the food, meeting the strict regulatory requirements of food production.

We have a professional after-sales maintenance team that can respond promptly after receiving a user's fault report. The maintenance personnel have rich maintenance experience and professional knowledge, and can quickly diagnose and solve equipment problems. At the same time, we have established a complete spare parts supply system and stockpiled sufficient original spare parts to ensure that the required parts can be provided in time during equipment maintenance, shorten the equipment downtime, and ensure the user's production continuity.